Amazing Browning steam shovels!

Posted by Chris Graham on 30th December 2021

Keith Haddock explains the fascinating history of Browning steam shovels that were developed in Ohio during the early 20th century.

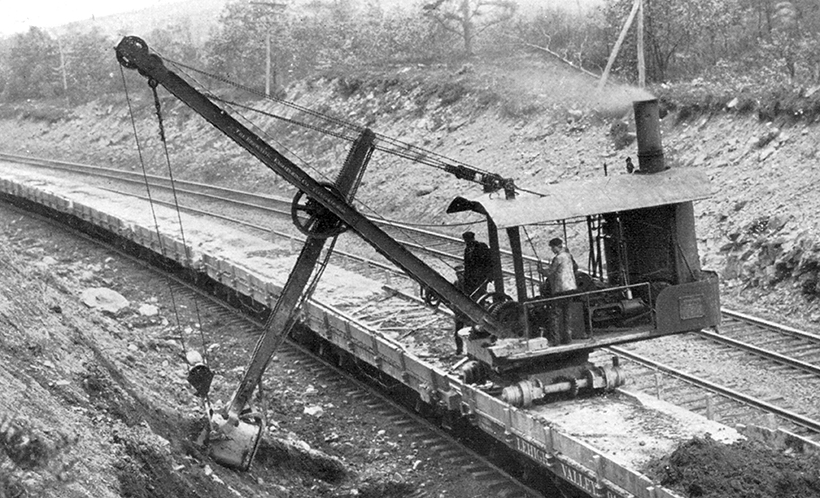

Browning steam shovels: This is Browning ‘No. 3 Steam Crane’ built by Browning Engineering Company converted for use as a shovel. Since the crowd motor was incorporated in the shovel boom, conversion from a crane required no change to the hoisting machinery.

In 1899, Victor R and Earl H Browning established the Browning Engineering Company in Cleveland, Ohio, USA. From the outset, this industrial company manufactured locomotive cranes as well as coal and ore handling equipment for use on the shores of the Great Lakes.

By 1908, the company was offering two sizes of rail-mounted, fully-revolving steam shovels in ½ and 1 cubic yard sizes and, by 1910, two sizes of heavy-duty railroad (half-swing) steam shovels appeared. The 1½-yard size weighed 45 tons in operation and carried a 50in x 10ft long boiler; the 2½-yard size weighed 75 tons and carried a 48in x 18ft long boiler. At about this time, the company introduced ‘Scraper Bucket Excavators’ (Draglines) in sizes from 1 to 3½ cubic yards, mounted on skids and rollers or rail tracks. From 1911, the company built, to special order, rail-mounted stripping shovels with booms up to 75 feet and dippers to 3½-yards capacity.

One of the large Browning draglines with buckets up to 3½ cubic yards capacity built in the early part of the 20th century. This machine is mounted on skids and rollers.

Locomotive cranes were always a prominent part of Browning’s business and, following success on the Mexican Railways with a large self-propelled railroad wrecking crane fitted with a shovel attachment, Browning offered shovel conversions for all its locomotive cranes and promoted their use for crane work as well as excavation duties. By 1912, the company had built a wide range of rail-mounted locomotive cranes (convertible to shovels), railroad wrecking cranes and the Browning Railroad Ditcher.

One of the most popular and long-lived products of the Browning Engineering Company was the Railroad Ditcher. This view shows how it excavated from the side of the train and gradually moved along the flat wagons, loading them as it proceeded.

Literature describes the operation of the Ditcher as follows: A train of empty flat wagons is provided, with the Ditcher placed on the one farthest from the locomotive. The Ditcher travels on two rail sections placed on top of the wagons and digs from the side of the train, loading the wagons behind it as it gradually travels toward the locomotive. As it progresses along the train, it transfers one track section forward after the other. When the train is loaded it is hauled to the dumping point and unloaded.

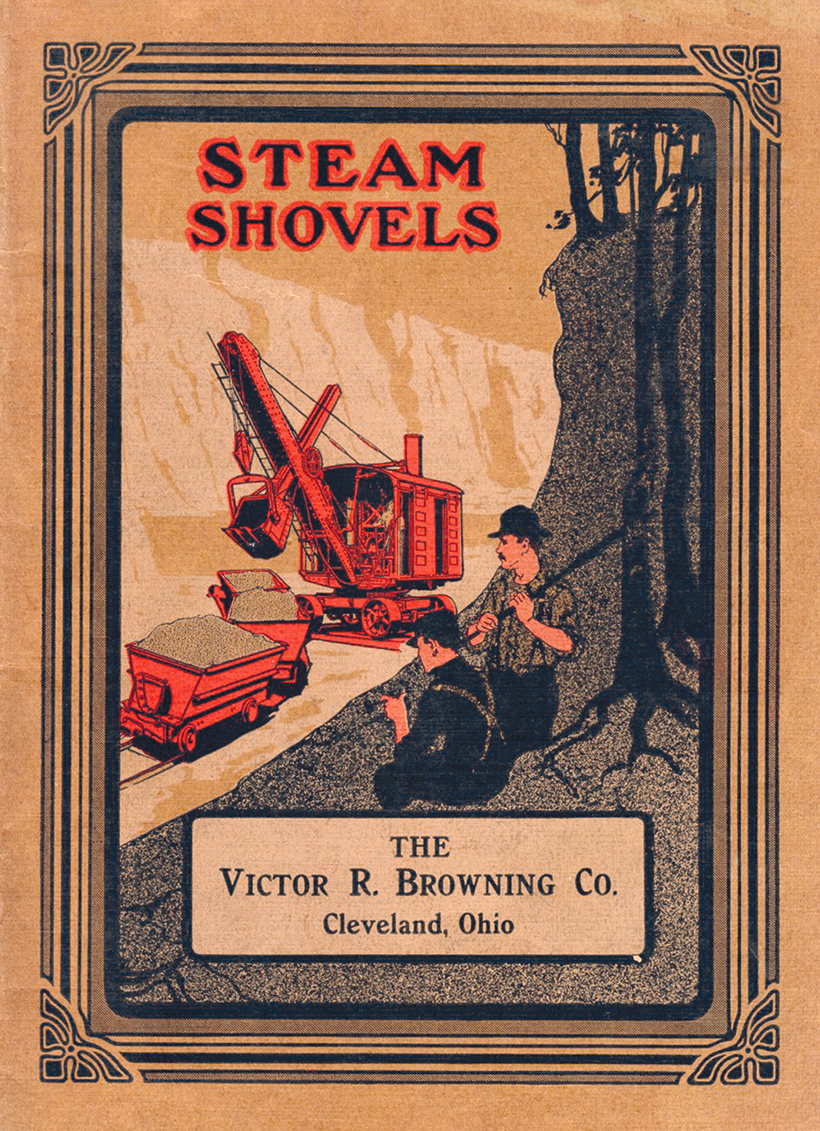

A general catalogue from circa 1926 describing the steam shovels of Victor R Browning Co.

In the early part of the 20th century, the Browning company prospered and additional manufacturing facilities were established under different company names. In 1908 three were listed: the original Browning Engineering Company with works at Collinwood, near Cleveland; the Browning Manufacturing Company with works at Mansfield, Ohio; Browning Foundry Company with works at Ravenna, Ohio. From 1912 to about 1930, the corporate history of Browning is poorly documented because it traded under a number of different names. Literature dated 1920 under the name ‘The Browning Company’ depicts revolving steam shovels, railroad ditchers, wrecking cranes, clam shell buckets (grabs) and pile drivers.

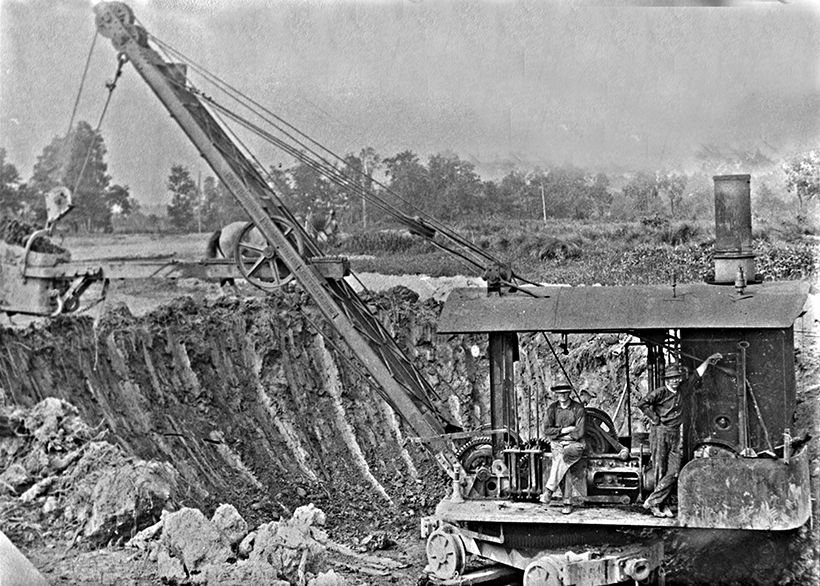

The driver takes a break while this early Browning rail-mounted steam shovel is photographed.

From about 1926, the company traded under the name Victor R Browning Co., founder Earl H Browning having left to pursue other business interests. By this time the company had built many types of cranes, including overhead types with grabs, dockside cranes, straddle cranes, ship unloaders, crawler and rail-mounted excavators, and rail-mounted stripping shovels.

This crawler steam-powered crane fitted with a grab was built by Victor R Browning Company in the mid-1920s. Its working weight was 47,000 pounds and the grab was rated at ¾ cubic yards.

The Victor R Browning 7/8-yard revolving steam shovel weighed 25 tons and carried a 20-foot boom and 12ft 3in handle. The main hoist was provided by a pair of 6½in x 8in steam engines, and the crowding and swinging engines were 4½in x 5in double horizontal reversing types. Standard crawler shoes were 20 inches wide. Power to the crawler drive sprockets was by chain from a horizontal propel shaft in the lower works, driven through a series of gears and shafts from the hoisting engines. Steering clutches were operated from the ground by the banksman, with levers provided at each crawler drive sprocket.

This Browning steam shovel is shown at work in a clay pit.

By 1928, the company was known as the Browning Crane Company, still headquartered in Cleveland, but steam shovels no longer featured in production. In the early 1930s, the name was changed to the Browning Crane & Shovel Company and new models of improved petrol and diesel crawler-mounted excavators were gradually introduced. According to sales literature, some of the models marketed in the 1930s included the XE and ME (½ yard), models E and E-2 (5/8 cu yd.), K-2 (¾ yard), A-1 (7/8 yard), F and F-2 (1¼ yard), and L-1 (1½ yard). Some of these models were offered as truck-mounted cranes and excavators.

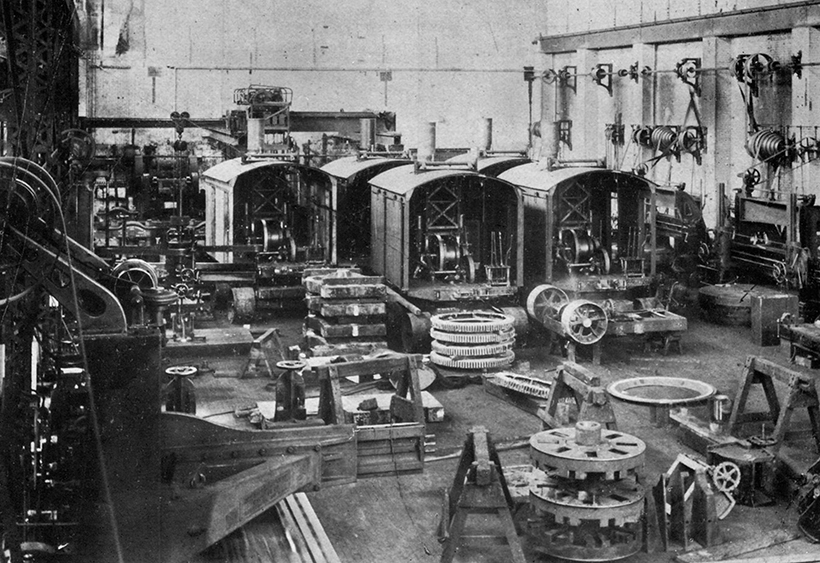

A view of the steam shovel erection bay in the Browning works.

Early in 1954, Browning Crane & Shovel Company was acquired by specialist crane builder, Wellman Engineering Company of Cleveland. Later that year, Wellman merged with McDowell Company, also based in Cleveland, to form the McDowell-Wellman Engineering Company. In 1960, this company was taken over by the Ohio Locomotive Crane Company of Bucyrus, Ohio, and continued to offer designs of Browning diesel-electric locomotive cranes until the last was supplied to Brazil in 1973.

For a money-saving subscription to Old Glory magazine, simply click here

Previous Post

County Donegal Railway request

Next Post

Stunning commercials at the Yorkshire Motorsport Festival