1902 Burrell lockdown restoration

Posted by Chris Graham on 6th April 2022

Simon Colbeck and Paul Vickery tell the story of the superb, lockdown restoration of a 1902 Burrell single 7nhp agricultural engine.

First season out at the South Bedfordshire Country Show at New Manor Farm, on June 30th, 2019. (Pic: Simon Colbeck)

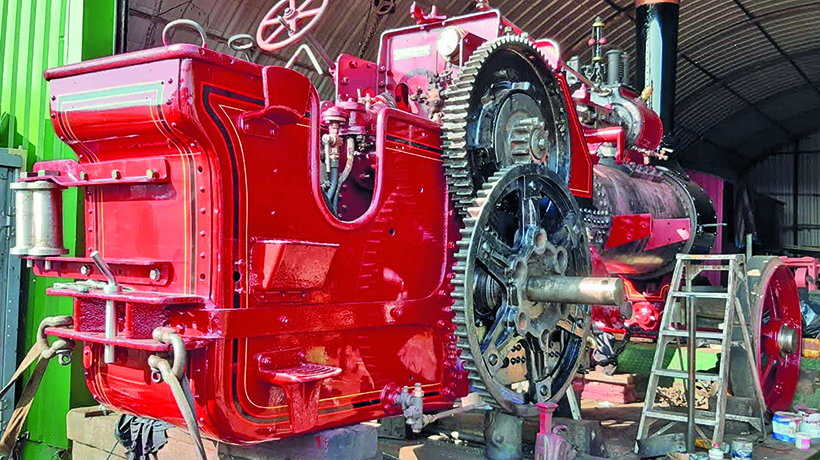

Last year saw the return to the rally field of many engines that have been subject to extensive restoration projects which have been completed during the Covid-19 pandemic lockdowns. One such engine is the Vickery brothers, Paul and Ian’s superb Burrell single 7nhp agricultural engine, No. 2507 of 1902. Now resplendent in a new lined crimson paint job the engine has been a highlight at local events following the resumption of rallies in 2021.

Paul and George Vickery enjoy a ride around the grounds of Old Warden, September 5th, 2021. (Pic: Simon Colbeck)

Often to be seen paired with another of the Vickery’s restorations, a 1926 Fowler living van, the brothers have been busy during lock down returning the engine to the condition it left the Thetford works when delivered to its first owners in Suffolk. Having caught up with the engine at a number of events in 2021 Paul Vickery takes up the story of the brother’s involvement with the engine and its subsequent overhaul.

George Vickery in control during a days threshing with the Burrell at Stotfold Mill Working Weekend on October 9th, 2021. (Pic: Simon Colbeck)

“Steam has always been in our family and with the help of our dad Jonathan we purchased our first engine together at a young age, a very derelict Aveling & Porter R10 roller which we restored and rallied over 19 years. Having really enjoyed the Aveling we decided it was time for a new challenge and set our sights on acquiring a traction engine, so with a heavy heart we sold the Aveling to go towards a new purchase.

Out on the roads in Bedfordshire, Paul and Ian road the engine wherever possible to local rallies. (Pic: Simon Colbeck)

Fortunately, dad spotted the advert in Old Glory for a 1902 Burrell single-cylinder general purpose engine available for sale on the Isle of Wight. Immediately the ferry was booked and on a misty morning, off we went to view the engine for the first time. As soon as the doors of the shed were opened, we knew this was what we had been looking for.

Paul and Ian take the Burrell out of the airfield at Old Warden. Behind the engine is Fowler living van No. 13918 of 1926. The van had been saved for preservation in 1954 by notable ploughman, Charles Roads. (Pic: Simon Colbeck)

“Originally delivered new on 9 September 1902 to Mr S Martin of Monewden in Suffolk, the engine was named originally The Pride of Monewden. It was ordered with copper chimney top, brass hub caps and the name sign-written on the lagging sheet and must have looked very smart when it left the Burrell works. By 1915 the Burrell was sold to Fenning Brooke in Henley, East Suffolk.

Burrell No. 2507 laid up at Wreningham in Norfolk in the 1960s. (Pic: Stuart Hines Collection)

“In 1921 it changed hands again to Norton Brothers of Wymondham, Norfolk, it was here that it was registered as AH 7105. In 1932 the engine then went to B Sheldrake of Wymondham in Norfolk who only had it for a year before passing it on in 1933 to Mr S Sheldrake of Heathersett, also in Norfolk. Here the Burrell was to remain until the end of its working days. The engine lay derelict and abandoned at the premises of RN Bothway of Wreningham, Norfolk. It is said that he wouldn’t let Mr Sheldrake collect the engine for scrap for one reason or another which meant the engine was saved from the scrap yard. It lay there until 1975 in a very sad state when it was finally sold to Fred Hollis of Chale on the Isle of Wight.

The Vickery’s first sight of the Burrell when they went to inspect it on the Isle of Wight in March 2019. (Pic: Vickery Family Collection)

“Den Phillips of Compton Bay, Isle of Wight bought it in 1976 and took on the big restoration job to get the engine back in steam. A well-known engine on the Isle of Wight it was rallied and showed for many years, being named Rusty Rose.

The Burrell stripped down ready for work to begin in 2020. (Pic: Vickery Family Collection)

“In the early 2000s boiler work was required and Mendip Steam carried out the boiler work then rallied it for a few years. In March 2019 Ian and I purchased the Burrell. Once home a fire was lit and we had a weekend getting to know the engine, the timing was out so the first job was to remove the valve cover and adjust the timing which made it sound much better.

The contrast between the old and new final drive gears. (Pic: Vickery Family Collection)

“Before the 2019 season we needed to do some work, a new chimney was required so this was removed and a new one fitted. The ride on the engine was rather rough as the engine was still on strakes and our children nicknamed the engine Bumpy Burrell. Wanting to road the engine as much as possible we decided to fit quad track tyres to the rear wheels to improve the ride.

Ian Vickery’s tool box was made for the Burrell during lockdown. (Pic: Vickery Family Collection)

“After an enjoyable 2019 rally season roading the engine to many local events it was decided that an overhaul was required as there was a lot of wear in the diff, second shaft and drive train. Stripped down to just boiler and tender, we could see what work was required. The first job was to make a new second shaft and bearings as well as new bushes in the differential.

The gear train fitted and painting of tender underway in 2020. (Pic: Vickery Family Collection)

The final drive gear on the second shaft which drives the winch drum was extremely worn and the winch drum was very loose on the back axle, indicating that it must have done a lot of winching in its life. A new gear was cut and as the winch drum had never been bushed from new it was bored out and a new bush fitted.

Burrell 2507 of 1902 sits under the trees in the grounds of the Shuttleworth Collection at Old Warden on 5 September 2021. (Pic: Simon Colbeck)

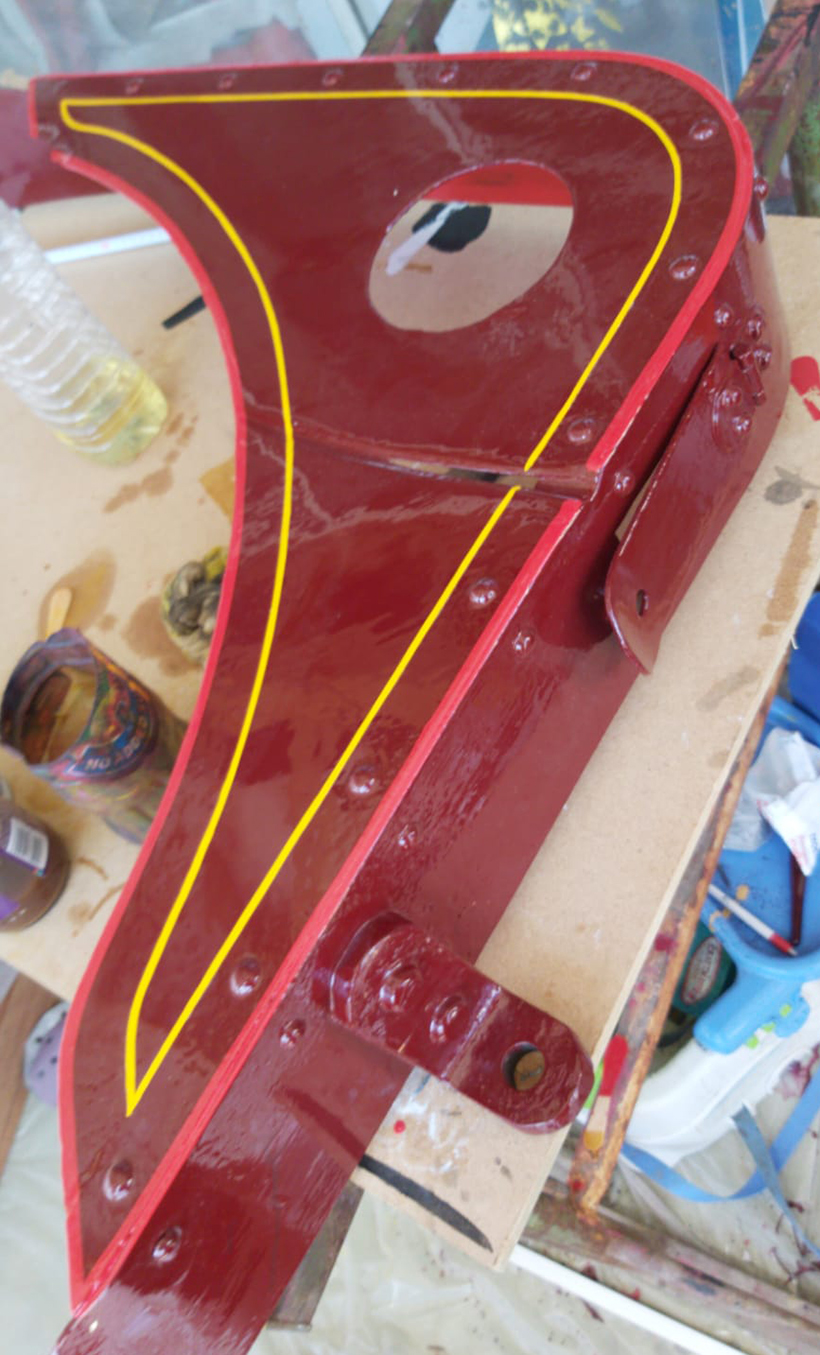

“With the arrival of Covid in 2020 it gave us plenty of time to get to work on the restoration, taking as much home as possible to work on during the lockdowns. Ian made a new wooden seat and toolbox for the tender and painted all the gear guards and after some practising, he also lined them all out. I took bits home for painting, polishing brass and steel work along with fabricating a new ash pan and producing new keys for all the gears. Our dad Jonathan was busy producing a new regulator rod, whistle fittings, pipe work, cylinder drain cocks and repairing the broken gear selector.

New lagging going on the boiler in 2020.

“Once the lockdowns started to ease, we were able to meet and get back up the yard and carry on with the restoration, fitting the bits we had all been working on at home. When assembling the engine, it became apparent that the piston was loose on the piston rod so a new piston rod was made and all the slide bars shimmed and adjusted.

Another job for Ian, the finished lined and painted wheel spokes.

The wheels were sand blasted and the rest of the engine was painted and lined; the build sheet never stated what colour it had been painted when new so we decided on Craftmasters Crimson Lake with traditional Burrell lining. We have taken great satisfaction in completing all the painting and lining ourselves.

Ian Vickery painted and lined the gear guard during the 2020 lockdown. (Pic: Vickery Family Collection)

“By the winter of 2020 the engine was back together and in steam. A 10-year hydraulic boiler test was carried out and all new lagging and sheets were produced. The engine was now really starting to take shape ready for the 2021 rally season which due to the pandemic was a bit slow, but we still managed to get out to a few events, including taking her back to the Isle of Wight Railway steam show. Between ourselves and our dad we have tried to do as many of the jobs on the engine ourselves and we would like to thank all the people that have helped us along the way with jobs that we couldn’t do ourselves, especially the help from our family, without them it wouldn’t have been possible.”

This feature is from the latest issue of Old Glory. For a money-saving subscription to the magazine, simply click HERE