1953 Bedford OSB tipper

Posted by Chris Graham on 10th February 2021

Given the quality of Terry Jones’ 1953 Bedford OSB tipper, you’d never guess it was restored 25 years ago. Peter Simpson tells the story.

Terry Jones’ superb 1953 Bedford OSB tipper was restored over a three-year period almost 25 years ago.

Terry Jones’ 1953 Bedford OSB tipper was restored over a three-year period almost 25 years ago, so its condition today is testament to the quality of the work carried out then. Twenty-five years is quite a long time in lorry-life; few that were new when this one’s restoration was finished, will still be on the road, and any that are will be either in preservation themselves, or seen as ‘preservation prospects.’

Yet the gleaming Bedford we see here wasn’t even new in 1995, and it certainly didn’t get a cost-no-object restoration. Rather, it was restored by a working man using his own efforts, along with help and favours from friends and business contacts.

Owner Terry Jones (right) with well-known local lorry enthusiast, Ashley Lovering.

Remarkable story

This story is made all the more remarkable by the fact that, for more than 20 years before Terry became involved, the Bedford was parked-up in the open and derelict, in a Herefordshire caravan park. What’s more, before that it was employed in one of the roughest environments of all – carrying stone from quarries.

Based in Port Talbot, South Wales, married to Doreen, and retired for the past 12 years, Terry Jones has spent his entire working life with lorries and machinery. He also worked his way up the career ladder, starting as a driver of lorries, before moving on to drive machinery such as excavators and crawler cranes. Eventually, management and a desk job beckoned, and he finished up as the transport manager for Andrew Scott, a large, local, civil engineering and construction company which celebrated is 150th anniversary in 2020.

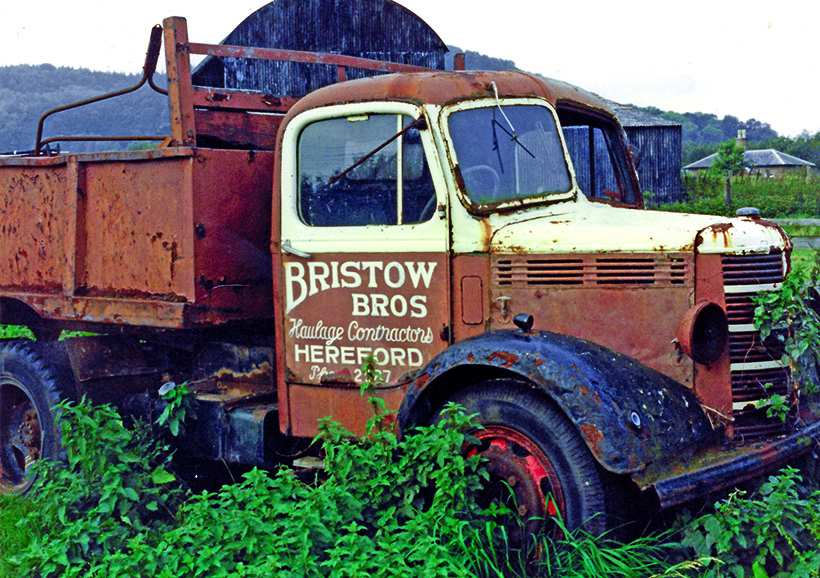

The Bedford ‘as found’. It was standing in the middle of a caravan park and basically been left to rot.

With this role came responsibility for overseeing maintenance and servicing across a wide range of vehicles, plant and equipment. Crucially in the current context, however, it also bought with it access to a large, and well-equipped transport maintenance workshop…

Plenty of help

Terry is keen to acknowledge the help he was given in completing the project by the management at Andrew Scott: “I could never have done it without their help.” Also, key to the job was one of the staff at Andrew Scott; a friend and old-school mechanic/fitter named Clayton Davies. Clayton had served his apprenticeship with the local Bedford dealership, knows his way around 1950’s Bedfords extremely well, and had also assisted “one of the firm’s bosses” with the restoration of a Bedford M.

Terry, it would be fair to say, has always had an interest in vintage engineering, of one kind or another; the Bedford currently shares garage-space with a Scammell ‘miniature’, and a miniature live-steam traction engine. A lorry restoration was, however, always on the wish-list and, with access to the facilities at Scotts, he had a chance to put that dream into practice.

Loaded-up for the journey back to South Wales and restoration.

He was ‘alerted’ to the existence of VSY 420 by a friend who spotted “a little lorry that might suit you” on a caravan park at Canon’s Prior, near Hereford. It’s actually an ex-military vehicle – though Terry thinks it’s always been a tipper – and was sold off via the famous MoD auction/disposal site at Ruddington, Nottinghamshire. From here, it was bought by the Bristow family, old-established and well-known tipper operators based in Hereford. Bristow ran a fleet of Bedford tippers, chiefly on quarry work and, at one point, had several. But, though as work contracted, so did the fleet and the lorry Terry ended up buying is thought to have been the last one they operated. By this point, however, many parts that had originated on other members of the fleet, had gravitated on to this one and, while the chassis/frame, suspension/steering and rear axle are original, a lot of the smaller stuff almost certainly came from other, scrapped Bedfords. The engine is definitely non-original, and thought to date from 1942.

Anyway, Terry and Doreen took a trip up to Herefordshire, and met up with the family, a deal was agreed and Terry returned with a Hiab-equipped flatbed to collect it.

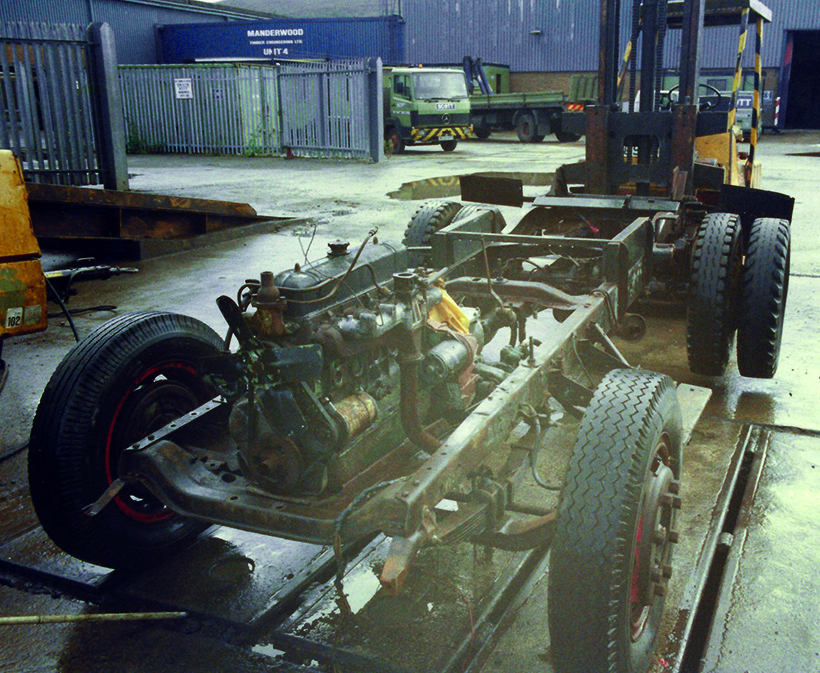

Stripped to a rolling chassis, and with some diesel down the bores in an (unsuccessful) attempt to free the siezed pistons.

You need friends

As anyone who’s tackled a lorry restoration will surely testify, while a certain amount of basic ability with tools goes a long way, there will always be areas where some specialist help is needed; things like machining, servicing or even sourcing parts, and it therefore helps a great deal if you have a decent circle of ‘contacts’ to call on for assistance. Terry’s position, of course, meant that he ‘knew’ a lot of people in and around the Neath/Swansea lorry and equipment maintenance industry. As usual, these were a mix of friends and business contacts, and a lot of people who were a bit of both!

He also freely admits that being the transport manager of a large, local firm with significant ‘purchasing power’, was often a great help when it came to persuading people to go that extra mile! It gave him quicker access to people who could make decisions and probably resulted in more “I’ll see what we can do” responses to requests for unusual parts, or providing services.

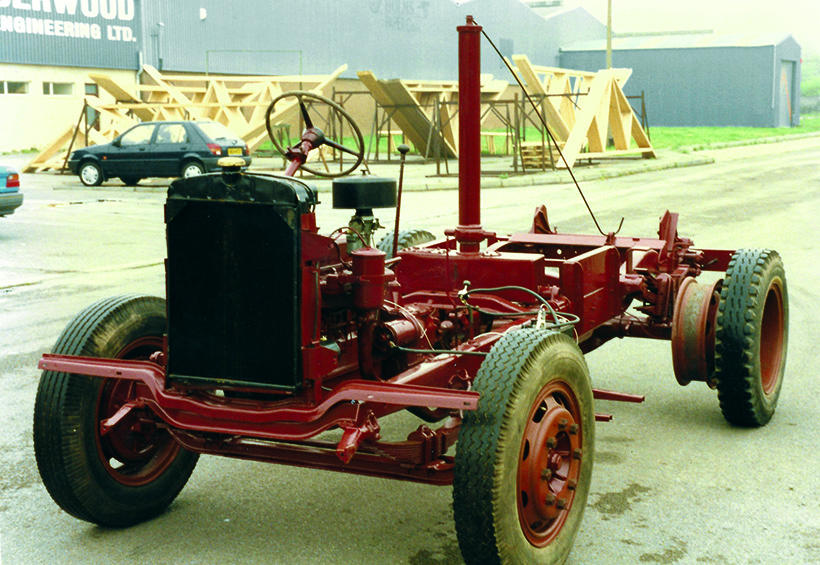

Chassis in primer. Most of the running gear turned out to be in surprisingly good condition.

He also spent a lot of time touring autojumbles and the like in search of parts, and also bought for spares a terminally-rotten Bedford O horsebox which, as we’ll see later, donated a number of useful bits. Even better, Terry was also able to sell the remains for further parts removal, and for more than he’d paid!

Back at the workshop, the first thing Terry and Clayton did was fully dismantle the lorry to rolling chassis stage and, subsequently, everything on that was removed, refurbished and refitted. “We took it right back to the last nut and bolt.” The chassis was shot-blasted, but turned out to be surprisingly solid, so was repaired locally as required and refinished.

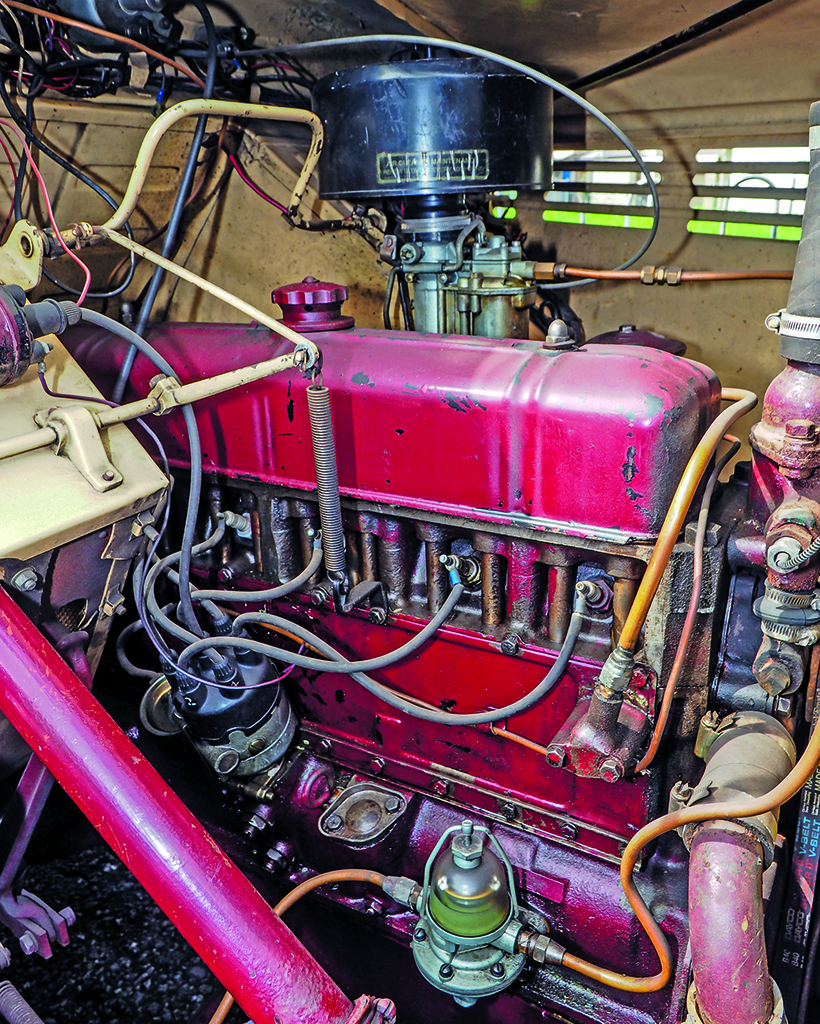

The engine needed a full rebuild due mainly to massive water ingress.

Even more surprisingly, most of the chassis running gear – bushes, shackles, kingpins etc., also turned out to be in good condition, and could be reused after cleaning up. Even the leaf-springs were OK once taken apart, cleaned up and reassembled using new bolts.

Engine problem

The 28hp Bedford diesel engine did, however, present a problem. Because the lorry had been left standing with its carburettor removed, rainwater had got into the bores, meaning the pistons were rusted solid. Terry was aware that this was likely to be a major issue when he dismantled the lorry, so tried the usual trade trick of soaking the piston tops with diesel, and then leaving the engine standing while work continued on the chassis. It didn’t work, and nor did any of the other usual methods. In the end, the only way that the pistons would come out was courtesy of a sledge-hammer after the cylinder head and crankshaft had been removed. Needless to say, a full rebore was required, together with new pistons, the latter being one of several lucky autojumble finds. A firm in Cardiff carried out the machining and supplied bearings. The rear axle was rebuilt by a firm in Swansea, and the gearbox from the spares-donor cattle truck was fitted because “it was better”, although the original one was still serviceable.

The cab interior was refurbished by Terry and Clayton, with help from a couple of local trim specialists.

Attention then turned to the cab, which careful use of the shot-blaster had confirmed needed significant welded repairs. Once again, “friends and contacts” helped out. Chief areas requiring attention were, as usual, the floors, wheelarches and the support panel under the front windows, together with the door bottoms. New front and rear wings were supplied by Vintage Wings & Radiators of Manchester, and paintwork was applied, using cellulose and traditional coach-painting techniques, by Tony Harris of Swansea, who Terry describes as “an excellent man.” The radiator grille now carried is a ‘one-good-one-out-of-two’ unit, made up using the best parts from the original and the cattle-truck donor. The cab interior was also refurbished by Terry and Clayton, with help from a couple of local trim specialists.

A lucky find

When it came to the tipper body, Terry had a spot of luck. The original steel body was very rotten and, in any case, he wasn’t too keen on retaining it, as he felt it was too heavy for the chassis, especially given that the Bedford’s load-carrying days were over. Accordingly, he decided to replace it with a period, wooden body. As well as putting buildings up, Andrew Scott also carries out demolition work and, at the time, the company was taking down a large school building which had a huge wooden roof lined inside, with some lovely tongue and groove wood. Clearly the longer lengths of this were required and resaleable, but the sub-8ft stuff had no resale value and, basically, was heading for the skip. This, though, was just what Terry needed to make his new tipper body. So, it was salvaged, made into a new body, and Terry was even able to ‘repurpose’ some of the metalwork from the rotten cattle truck’s body.

As mentioned earlier, a lot of bits and pieces were sourced from autojumbles; this included, in particular, most of the electrical items – lights, switches and so on – which needed renewing. This was made easier by a lot of the same stuff being used on contemporary cars. A complete new wiring loom was, however, made from scratch by Clayton, using traditional, old-school ‘one-wire-at-a-time’ techniques.

Keeping it local

In 1995, after three years of evening and weekend work, the project was finished. Since then, Terry and his Bedford have been regular attendees at shows and events around South Wales. You probably haven’t seen it though as, although Terry and Doreen do tow a caravan behind it for occasional overnight stays, he doesn’t tend to travel that far from base. The furthest regular-ish run that they do is to the ‘Welland’ show, at Upton-on-Severn.

Terry describes his Bedford as “lovely to drive”, and it will cruise quite happily at 40-45mph. The only significant issue to have arisen during his ownership came shortly after it went back on the road, when a series of fuel system blockages and intermittent restrictions – especially when the engine was pulling hard – proved tricky to trace. All fuel lines had been renewed during the restoration, and the tank cleaned out. The cause was eventually traced to a significant number of dead spiders in the fuel line unions, which hadn’t been cleaned out properly. Once that was done, normal running was restored, and has remained ever since.

For Terry, though, probably the best aspect of this project has been some of the people he’s met through the worldwide lorry and Bedford communities. “I now have friends I talk to regularly in Australia and New Zealand, and I’ve been to Malta a few times.”

Sadly, it can no longer really be said, as Bedford famously did of its products, that “you see them everywhere.” Bedford enthusiasm, however, is truly still to be found in every corner of the world.

For a money-saving subscription to Classic & Vintage Commercials magazine, simply click here