Roadless Ploughmaster 90 restored

Posted by Chris Graham on 11th February 2021

Tony Hoyland discovers a beautifully-restored, ex-demonstrator Roadless Ploughmaster 90 that’s been brought back to life in the most exacting way.

Richard Mason with the Roadless Ploughmaster 90; the late-afternoon burst of sunshine really makes that fresh paintwork pop!

I think it’s fair to say that I, pretty much like the rest of you reading this, have been starved of the privilege of walking up and down splendid collections of tractors lined-up for parade throughout 2020. So, it was an unexpected and welcome surprise to go and see the latest restoration by Jack Ashton, whose last project, a Farmall H, was featured in the March 2020 issue of Tractor & Farming Heritage magazine. This time the tractor was a Roadless Ploughmaster 90, a restoration he’d just put the finishing touches to and returned to its owner Richard Mason, who lives on the outskirts of Boston, in Lincolnshire.

Not only was I met by this latest piece of immaculate work, but also by a mind-boggling array of Roadless tractor history. This included Roadless examples of E27N Full track and Half-track crawlers, a Blue Grey Super Major full track crawler plus Dextas, Super Majors and much more. The theme today, however, was Ploughmaster, and the newly-restored 90 sat alongside a mouth-watering selection of the Ploughmaster range, including the 6/4, 75, 90, and 120 tractors.

Jack did all the paintwork on the tractor, apart from the nose cone, bonnet and fuel tank cowl.

Richard bought the Roadless 90 at a Cheffins sale some 10 years ago. He explained: “I’ve been collecting for 14 years now. I saw a Super Major at the Carrington Rally some 15 years ago and then went and bought one, and that was the start of it all.”

Company demonstrator

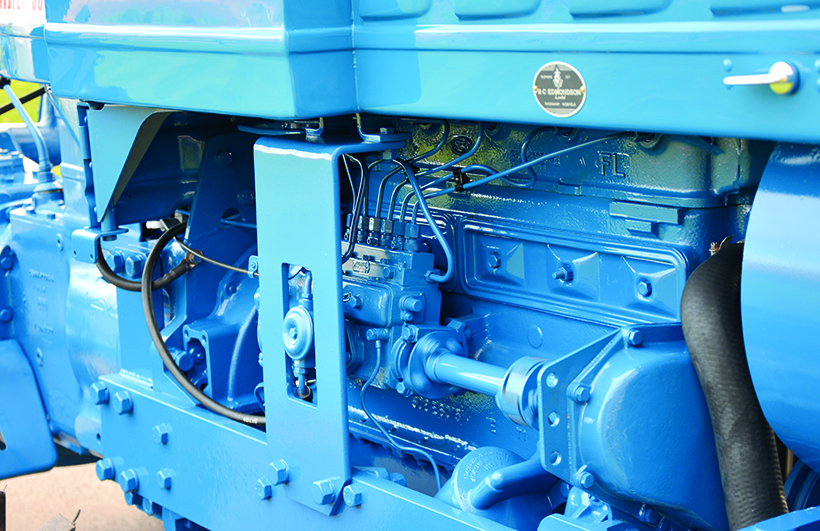

“It used to be a Roadless demonstrator for the Eastern Counties, and I have a copy of the build card for the Ploughmaster 90 from John Bownes, who took over the Roadless business. It was ordered on January 11th, 1966, as a demonstration tractor, and was supplied to RC Edmondson on September 7th, 1966.

Just 4,323 hours on the tractor meter; let’s hope there’s plenty more in there if needed, after the engine rebuild.

“Unfortunately, after that, the trail runs cold on the tractor’s history. It’s fitted with an age-related plate. Fast forward nine years, and ‘master restorer’ Jack Ashton took on the nut-and-bolt restoration of the Ploughmaster 90, starting work in January, 2020. Just nine months later, the task was completed. The Ploughmaster 90 was only produced for a year (1965-1966) and, according to Stuart Gibbard’s book Roadless – Story of Roadless Traction from Tracks to Tractors, there were only 127 produced.”

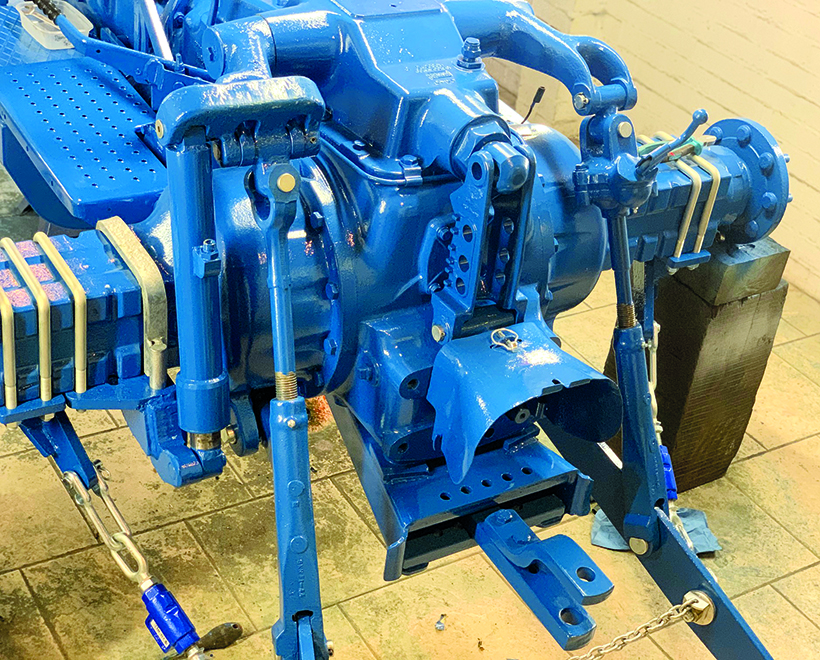

The Ploughmaster 90 was the successor to the Ploughmaster 6/4. It still used the Ford 5000 skid unit, and Roadless used the Ford 590E six-cylinder engine. As per the 6/4, the model 90 possessed the Roadless short wheelbase, this had the benefit of putting more weight on the front drive axle to increase traction. However, there were reliability problems with the hydraulics and front axle and, just one year later, the Ploughmaster 95 was launched. This new tractor was fitted with Ford’s more powerful, six-cylinder 2703E engine, and there were other modifications which included upgrades to the hydraulics and front axle.

Now the restoration work is done, Richard and Jack are on the lookout for a Winsam cab to finish the job.

Restoration issues

When Jack began the restoration, he soon discovered that someone had been there before him, and that the tractor had been poorly-restored in the past. As a result, there were issues with the front axle, and the engine and clutch underwent a complete rebuild. Jack got a lot of his original spares for the restoration from John Bownes Ltd. He said: “It was unreal to get the new/old stock from him, items like the seals came in their original wax paper wrappers, as they were supplied years ago; that’s something an engineer appreciates!

“The restoration only took nine months, but the Coronavirus pandemic slowed things down a little. For example, I’d sent the injectors and injector pump away for overhaul, and they sat there waiting to be worked on while everyone was in lockdown.”

When Roadless opted for a more powerful engine than the Ford 590E six-cylinder, it marked the end of the line for the Ploughmaster 90.

Perfect paintwork

Jack did all the paintwork on the tractor, apart from the nose cone, bonnet and fuel tank cowl. These panels were all badly damaged, so they went to a professional to be repaired and painted. He added: “The bonnet is the original, that was altered at the factory to make it longer, and to allow space for the battery. However, it had started to bow, and was showing signs of poor previous repairs.

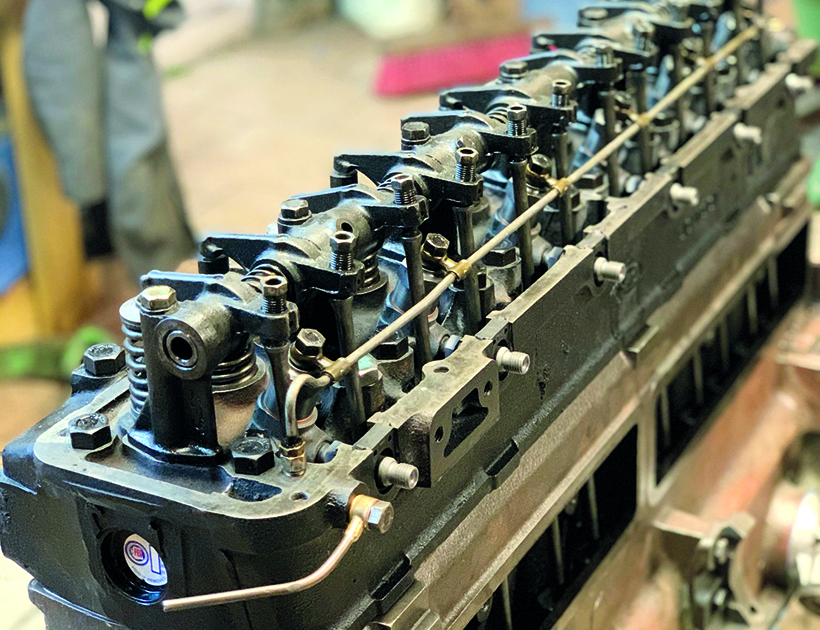

“The issues I came across during the restoration of the engine included damage to No.5 on the cylinder head. It looked like historic damage, possibly caused by a dropped valve. So, Richard sourced a secondhand one from a friend, Paul Wright, which we had reconditioned by the Welham Group.

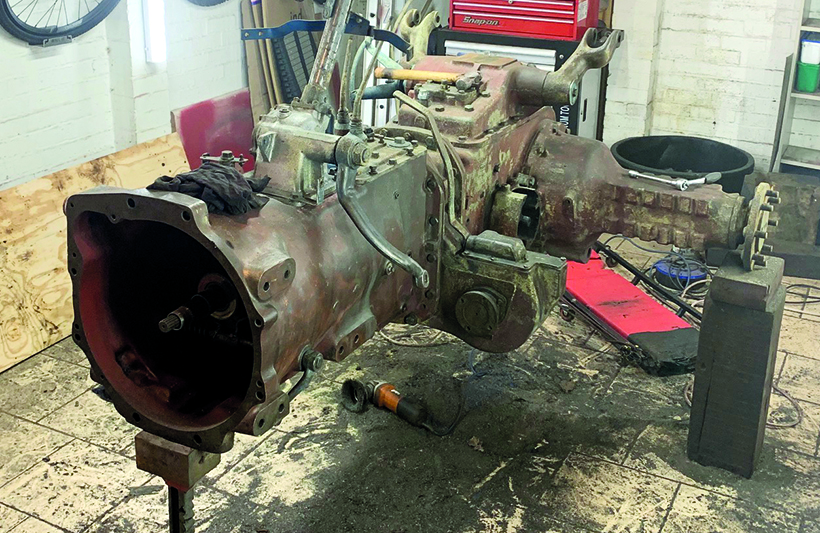

The tractor had been restored in the past, and new paint had been applied on top of the original coating. So it was necessary to take everything back to bare metal to eradicate the rust. (Pic: Jack Ashton)

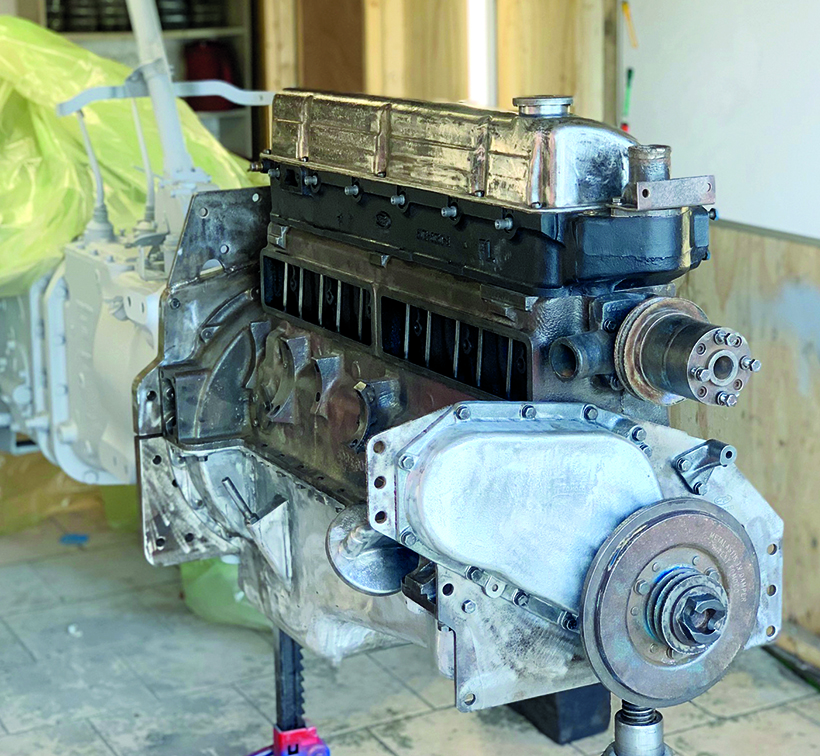

“When the tractor came in, it ran but didn’t start well and smoked while running. The fuel-injection pump was well past its best, so we had it and the injectors reconditioned by the Welham Group in Leicester, as well. The same company also supplied the parts for the engine build, and I found it a very good operation to deal with.

“The clutch was in very good order, so just needed stripping down and cleaning. The axle was fully stripped as there were small cracks to be welded on the main body. Everything else was in good order, so it was just a case of rebuilding with new seals and gaskets. Then re-filled with new semi-fluid grease.”

It was easier to build the engine on the floor. The final job was setting-up the tappets after fitting the rocker assembly. (Pic: Jack Ashton)

Planning for the future

Looking ahead, Jack would like to carry on with more restoration projects. “For now, I’d like to carry on as I am,” he says, “and do the odd one as a hobby. To do any other would mean doing it somewhere else, or extending the garage.”

Speaking of extensions, Richard has a few tractors which will barely fit into his existing shed, and has his eye on expanding his collection with models such as the Muir-Hill 121. With this in mind, we looked at a patch of ground nearby during my visit, which he’s already earmarked for another shed, if all goes well. Watch this space. In the meantime, he’s just hoping that we can all return to taking tractors to shows, on road runs and to working events again soon as the pandemic eases and these events start up once again.

After the engine rebuild was complete, it was fitted back on to the tractor where it would be safer and easier to paint. (Pic: Jack Ashton)

Richard was keen from the start that all the linkage fastenings should be anodised, to make them stand out and all match. But, at the same time, he kept as many original parts as possible. (Pic: Jack Ashton)

The axle was fully stripped so that the small cracks found in the casing could be welded. This also allowed its general condition to be properly assessed; important as its history was unknown. (Pic: Jack Ashton)

Once the axle was rebuilt and painted it was nice to finish it off with a new, Roadless serial plate, that was supplied and stamped by Bownes. (Pic: Jack Ashton)

For a money-saving subscription to Tractor & Farming Heritage magazine, simply click here