1956 David Brown towing tractor restored

Posted by Chris Graham on 18th April 2022

Bernard Holloway pays a return visit to an enthusiastic collector with a flair for restoration, to see his 1956 David Brown towing tractor.

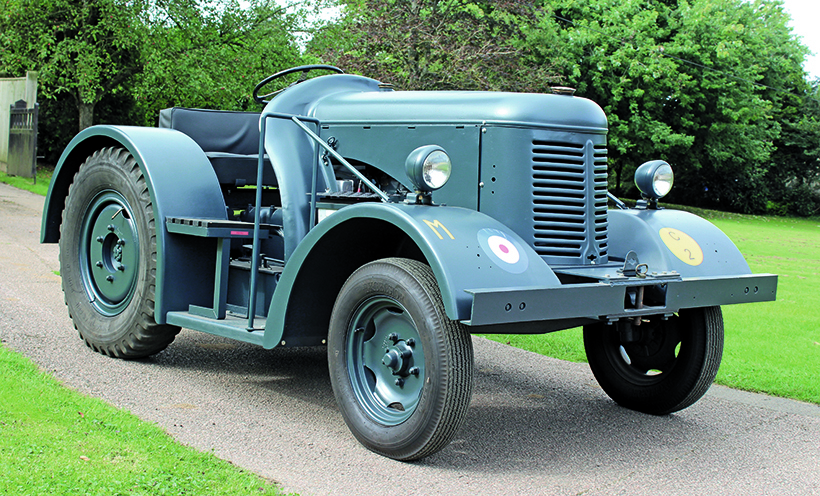

Graham Cook is justifiably proud of his repair and restoration of the 1956 David Brown towing tractor in its RAF blue-grey livery and what a fine tribute it is to his late stepfather, Ron. Yes, a few items are outstanding, but what project does not have them?

During a pleasant day in the company of Graham Cook and his stepfather, Ron Tibbs, we sat around discussing their collection of tractors, the various advantages of each model and the problems encountered in respect of acquisition, repair and restoration.

Among them was one machine that was out of context with the agricultural offerings from Ferguson, IH, MF, Fordson and assorted Case and McCormick prairie tractors – a Air Ministry, 301C VIG/1A AM2 light towing tractor, undergoing restoration.

That visit was eight years prior and, aware of my earlier interest in the tractor, Graham recently asked me if I would like to see the finished ‘restoration’ or more appropriately ‘repair’ that had taken almost 10 years.

A David Brown tug delivers a train of bombs to a De Havilland Mosquito bomber in March 1945. This photo appeared in the September 2014 issue of T&M, as part of a Tractors at war special feature.

While it endured a hard Ministry of Defence service life and certain repairs would be inevitable, one event during December 2012 almost put paid to it for good.

Where to begin?

In the intervening years Ron sadly died, but his legacy lives on. A man of varied interests, he placed aviation and militaria high on his list, alongside agricultural machinery. Consequently, he and his wife, Janet, were frequent visitors to air shows, and this took them to the Royal International Air Tattoo (RIAT), at RAF Fairford. As an aside, this year’s show, after a hiatus due to the Covid-19 pandemic, is scheduled for July 15-17th.

During their visit in 1989, the pair would have enjoyed a packed day of aerobatic displays by fixed and rotary-winged aircraft, including frontline fighters such as Tornado and Phantom, together with old favourites like Meteor and Vulcan plus helicopters from Westland and Aerospatiale.

Recovery well underway. The trailer is hardly damaged, thanks to Graham’s design, and note that the tug was in good condition prior to the accident. (Pic: Graham Cook)

Of particular interest to the packed crowd that year was a rare opportunity to get up close to the clandestine SR71 Blackbird ‘spy plane’ – one of only 32 built and on static display probably because its huge turning circle in flight was not suited to air displays. But I digress.

That year an RAF aircraft-towing tractor, 55 AN 37, was an auction lot scheduled to cross the block. Ron had no prior intention of buying a tractor at the show but, never one to let the grass grow under his feet, he decided to bid. Why? Largely because it provided a link between his interests and, therefore, the prospect of ownership was too good to miss.

When the gavel fell for the final time, Ron became the new owner and wasted no time loading it onto a hired trailer for the trip home to Surrey. Cosmetically it was ‘all there’, and representative of a typical service machine that had endured its fair share of knocks and dents, scarring the faded, blue-grey RAF livery. But, importantly, it was a runner – although the indications were a good service and top-end overhaul would not go amiss.

Graham fabricated the rear hitch, seat base and fitted new instruments. Note the slatted seat and grab handle fitted to the running board on each side.

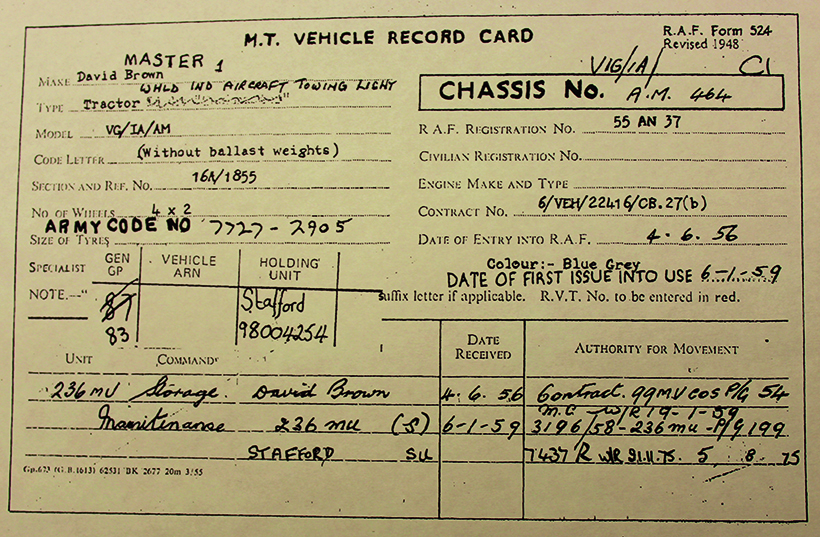

Upon inspection of documents received with the tractor, the Motor Transport (MT) Vehicle Record Card indicated that it was delivered to RAF Stafford, Holding Unit, Worcester on June 4th, 1956, and given a code number ‘7727-02905’, and a date for the ‘first issue into use’ of January 6th, 1959 – an indication that it had been stored, assumed unused, for that period (circa two-and-a-half years.)

It was one of batch of 28 supplied to the RAF as David Brown Light Aircraft Tractors in 1956; coded: 55 AN 34 to 55 AN 61. The serial number 464 also confirms that it was among the second batch of the type ordered by the MoD, and manufactured between February and June 1956, hence the VIGA AM2 nomenclature, and thought to have come off the line in May of that year. The initial batch, designated VIGA AM1, was built between March and December 1952. Petrol versions were designated 301C and diesel 301D.

At this point I must acknowledge the help received from Stuart Gibbard and the David Brown Tractor Club, for enabling me to flesh-out this information.

The replacement for the fractured section of chassis can be seen here in red. (Pic: Graham Cook)

This later production model is fitted with a standard, dry-plate clutch and is unlikely to have been extensively used to move heavy aircraft even though the MT card details designate it as an aircraft-towing tractor. Preference at that time was, if available, to use a heavy version fitted with a fluid drive Brockhouse torque converter – a later model spec – to mitigate snatch when towing.

Graham’s tractor was probably used for lighter duties, he believes at RAF Cosford, for general haulage. However, simple slatted timber seats fitted to each running board, may be indicative of its use to ferry crew around the airfield for training purposes on various equipment and aircraft; one of the base’s major roles since 1938. However, time has eroded our knowledge as to its duties and it’s unlikely that we’ll ever know with certainty.

Portent for the future

After enjoying the tractor, Ron decided to sell it on to Stuart Gibbard – an author and historian well-known to regular readers of T&M.

Unceremoniously pulled from its motorway drainage ditch resting place. Luckily, no fellow road users were injured, and Graham was exonerated by the police of any wrongdoing. Note the position of the front axle. (Pic: Graham Cook)

Loaded onto the trailer and properly secured, Graham and Ron began what turned out to be a short journey, to deliver it to Stuart via the biggest car park in the world, the M25. And, that day, thanks to the tractor, the motorway lived up to its reputation. The pair could never have imagined the nerve-racking event (Graham was slightly more explicit in the telling) that would prematurely halt their journey.

He recalls: “We had only driven a few miles on the inside lane when the trailer started to sway and the events that followed appeared to occur in slow motion but in reality, according to the police who were monitoring motorway CCTV cameras, it lasted no more than a few seconds.

“To counteract the sway, my initial reaction was to increase speed. This increased the pendulum action of the trailer and the steering of the tow vehicle started to become unresponsive.”

Albeit 10 years later, this is the section that broke away from the front of the tractor’s chassis. A partial and undiscovered hairline crack across its width extended and sheared during the transportation.

As that action was ineffectual, he gently eased off the throttle, traction was lost, and the trailer swung even more violently. From this point the pair were mere passengers, and the situation wasn’t going to end well. Graham continued: “It was just a matter of when the accident would happen and where we would end up on the carriageway – an uncomfortable feeling.”

As every other action had failed, Graham’s last resort was to apply the brakes gently. Unfortunately, as the rig slowed the trailer broke free of its tow and slewed, fortunately, towards the hard shoulder.

In the chaos that followed, the tractor broke free from the tow vehicle and the trailer, apart from a section of front axle still attached to the trailer. The tow vehicle – free of its burden – spun three times after hitting the centre reservation and wasn’t in the rudest of health when it came to rest. As for Ron and Graham, they were badly shaken and more than a little stirred! By luck, fate, or whatever term you wish to use, no other road users were caught up in the incident.

It takes skill to bend a radiator to this profile!

What happened?

As it transpired, the bolted-on front section of the tractor’s chassis, carrying the axle, had cracked clean across its width, shearing off behind and diagonally across the reinforcing webs. The assumption is that this was because of a combination of pressure from restraining straps and a hidden, age-related crack in the casting.

This failure allowed several tons of by now improperly restrained machine to move to the back of the trailer, which was seen by the police overhanging the tail just before the crash. No amount of juggling with speed or steering could have affected the outcome.

After a meticulous examination at the scene and a thorough interview, the police were satisfied that Graham, much to his relief, could not have done anything to mitigate the accident and thoughtfully provided a letter in confirmation for his insurance company. As Graham’s ruefully quotes: “Years in the making and 30 seconds in the wrecking!”

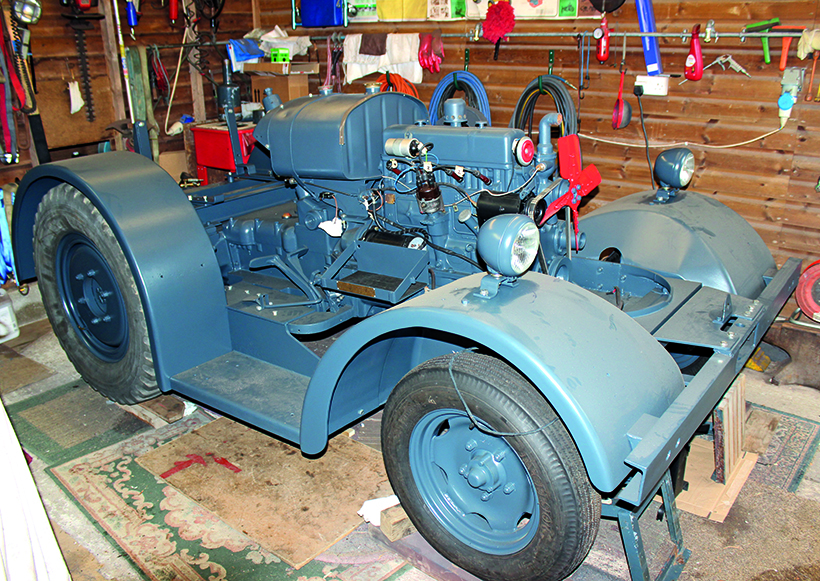

My first glimpse of the tractor, eight years ago. The project took almost 10 years to complete, due to Graham’s varied interests. Plus, as he delved deeper into the project, he took the opportunity to conduct other works.

Prior to this, Graham hired trailers to transport his tractors, but after getting deeper into the hobby with Ron, he decided to build his own twin-axle version constructed with steel channel and box sections. He used it that day and its robust construction was deemed by the police to be a major factor in reducing the severity of the accident.

So, wreck recovered and the car park once again in full use, an unscheduled return was made to the tractor shed. So, if you were stuck on the M25 on a December day all those years ago while the wreck was recovered, Graham’s your man!

He explained: “An examination back at home revealed an historic, rusty, hairline fracture across part of the chassis, and it was clear to see where this had continued to open up, during the course of the journey, easily identifiable by a line of bright metal. This had allowed it to shear, leaving the tractor improperly restrained and free to slide down the trailer bed.

The damage done

So, what were the principal areas of damage? Well, the front end had taken the brunt of the impact, as the tractor had slammed and overturned in the ditch. Part of the front axle was still attached to the sheared section of the chassis and required replacement, together with a complete front section for the front of the chassis. The rear hitch was buckled and beyond repair.

The restored tractor looks stunning and is a credit to Graham.

The tinwork had taken a beating during the accident and was distorted and creased. The bulkhead shroud had been bent against the dash area and the bonnet, side panels, grille and radiator were also suitably modified by the impact. The dash panel was misaligned and, consequently, the instruments had seen far better days. The steering wheel, column, box and seat were all irreparably damaged, meaning that replacement was the only option.

One piece of good news was that the robust, 3⁄8-inch steel mudguards had fared well and were hardly dented, but the damaged petrol tank and rocker shaft were beyond repair, which put paid to any idea of starting the engine.

The rest of the mechanicals were serviceable and, following a thorough inspection for cracks and distortion, the remainder of the chassis was declared sound.

The completed MT record card – RAF Form 524 – is a great reference tool to accurately determine vehicle details.

So, to cut an exceptionally long story short, the tractor was rebuilt as and when Graham found the time between his work as an engineer, as an enthusiastic member of SEVAC, pursuing his interests in agricultural machines and improving his ploughing skills with his B-275.

He says: “Yes, it took me some time, but I also managed to squeeze in the restoration of a Series II Land Rover and obtaining the various rare and hard-to-find parts wasn’t straightforward. In addition, the more I delved into the project I decided to take the opportunity to undertake work that wasn’t strictly necessary for its repair, such as an engine rebuild.

“The onset of Covid-19 in 2019 was the catalyst for me to complete the project, as restrictions left me with time on my hands. By 2020 it was running and with only a few outstanding jobs, but now there were no venues to show it at because of Covid restrictions!”

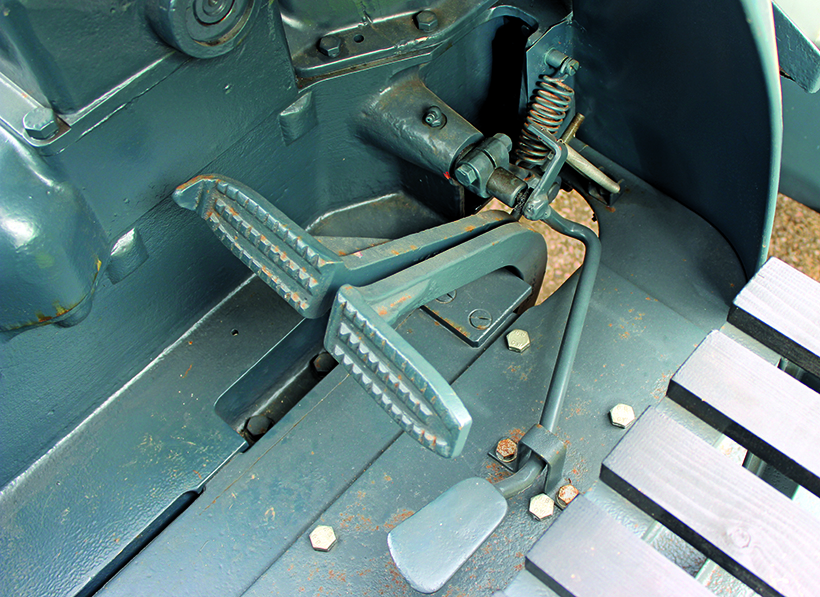

Foot throttle and brakes.

The necessary parts for the rebuild were sourced from all over the country via the usual sources – the internet, word of mouth and specialist suppliers such as Peter Williams of David Brown Tractor Parts, whom Graham recalls was particularly helpful when sourcing the steering box.

Fortunately, Graham knows his way around a piece of steel and has the knowledge and equipment to make almost any component and is more than capable of cutting and fabricating rare parts from scratch, such as the rear hitch.

His panel-beating skills are proficient and the shroud and various dents and defects to the salvageable tinwork were dollied to their original profile. And, as someone who spends his working day rebuilding engines, he certainly had no need to outsource the engine work.

The mudguards are made of 3⁄8-inch steel and were hardly damaged, such is their strength. Graham redressed the ‘scuttle’ back to its original profile.

One replacement item that has proved problematic to source is the petrol tank. So, as an interim measure, a dual-fuel petrol/TVO tank has been fitted.

There we have it, one David Brown restored and ready for use. Will Graham sell it? Absolutely not, or at the very least – if you buy it, you transport it!

This article is from the latest issue of Tractor & Machinery magazine, and you can get a money-saving subscription by simply clicking HERE

Previous Post

1903 Peckett 0-6-0 engine gets enhancements

Next Post

1954 Commer Superpoise breakdown lorry