1959 Fordson Dexta running again

Posted by Chris Graham on 9th April 2022

Gary Hawkins reveals his latest acquisition – a 1959 Fordson Dexta that he worked in the 1970s, and which is back in running order now.

Gary Hawkins with an old friend; the 1959 Fordson Dexta he used to work in the 1970s.

When I was at school all I ever wanted to be was a tractor driver. At the age of seven I was lucky enough to start my tractor-driving career, when Mr French, the farmer near my home, taught me all of the basics on his 1959 Fordson Dexta, while we loaded potatoes after picking them during school half-term.

I loved this little tractor, as it was much smaller and lighter to operate than some of the others on the farm. My reversing skills were honed with this tractor and a trailer before I was let loose on one of the two Ford 4000s owned by the French family. While I felt quite at home driving them, it was always a bit sweaty operating a Ford 4000 – with no power steering and pedals that my skinny legs couldn’t operate with any finesse!

Although Ford had chosen to mass-produce a single model, the Major, in a bid to keep costs down, it was quite clear that not everyone, including me, needed or liked large tractors. The success of the Ferguson System proved that there was a place for a smaller tractor and so, in November 1957, the Dexta was launched to the delight of many farmers.

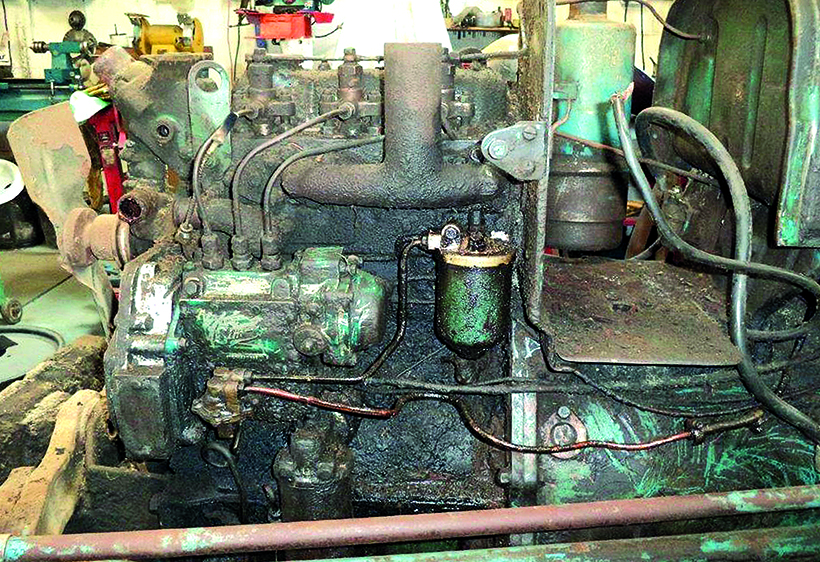

The Dexta before the renovation project started!

The new tractor was finished in a blue and orange livery and was based on the American-built 8N model, but with several modifications to make it better suited to European farms. At its heart was a 144cu in, three-cylinder engine built by Perkins, in Peterborough, using castings made at Dagenham.

It developed 32hp and enabled good fuel economy, great low-end torque and was easy to start in all but the harshest of conditions, featuring a six-speed transmission with differing ratios depending on market and intended use.

The Dexta had a three-point linkage and was the first Fordson model to be fitted with draft control, for soil-engaging implements. A dual clutch, providing ‘live’ power take-off and hydraulics, was optional.

Narrow and ‘Highway’ versions of the Dexta were introduced in 1960 to appeal to sectors other than agriculture, and a four-cylinder, spark-ignition engine was also offered for various export markets.

Generous helpings of oil, grease and dirt had protected the little Dexta, and given it a rather nice patina!

The Fordson Super Dexta, first seen at the end of 1961, was powered by a 2,500cc (152cu in) engine with a Simms Minimec, mechanically-governed fuel injection pump, and produced a heady 39.5hp.

Ford’s final incarnation of the Dexta was the New Performance Super Dexta, finished in blue and grey, introduced in 1963. Fitted with an uprated injection pump, the ‘new’ tractor produced a healthy 44.5bhp.

Production of the Dexta ceased in July 1964 and tractor production switched to Basildon, where the new 6X range of models was to be built – including the 2000 and 3000, known as the Dexta and Super Dexta respectively.

High hours

The Frenchs’ Dexta was 10 years old when I first got to know it, and the tractor maintained its place on the family’s market garden until about 2008, having done many hours with a planter and sprayer.

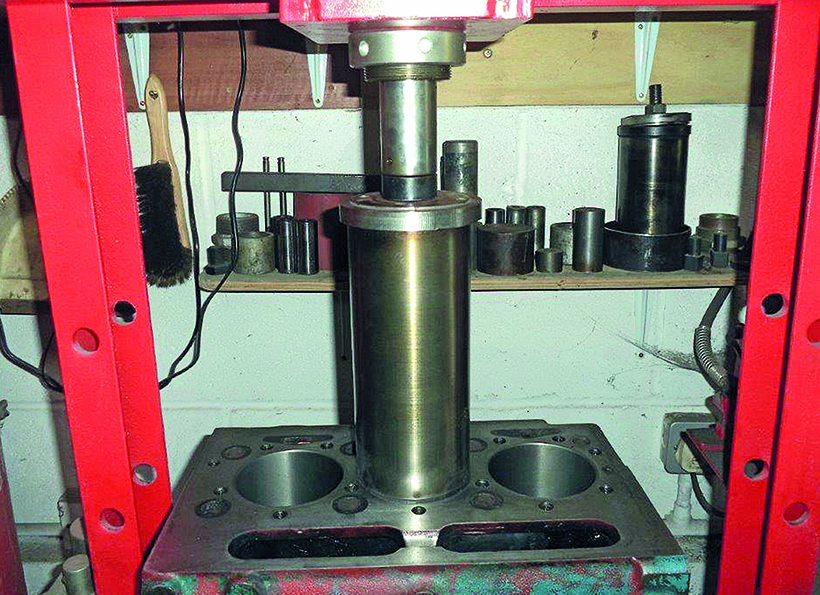

The 144cu in, three-cylinder engine was dismantled and overhauled.

Mr French retired the tractor to the barn, with supposedly a noisy knock on the engine, and that is where it stayed. Sadly, Mr French died more than three years ago, and his farm is now in the hands of new owners.

As the Dexta was to be sold after Mr French’s death, the family allowed me to take ownership of the tractor, which was very generous, and so I set myself the task of getting the tractor up and running, while leaving it looking as original as possible.

I was told by Ian French that the tractor had done more than 10,000 hours in his estimation, with the hour meter broken at around 8,000 hours. I know from the log book that the tractor was regularly serviced up until about 1981, when it took more of a subs bench role, with spraying as its main task.

The thing I always remembered was that the tractor always hunted on tickover. This is interesting, as I can see from the log book that the pump was serviced and overhauled three times, including being replaced at one point. Yet still it hunted. Thankfully, the overall cosmetic condition of the Dexta, once brushed off, wasn’t too bad, but there was plenty of work to be done mechanically.

10 years’ storage had allowed mice to set up home in the electrics. This area was nicely refurbished by Ian Linch, once tidied up.

As pleased as I was to have the Dexta, I was concerned about how I’d drive it. I was involved in a serious accident in 1990, and lost my left leg above the knee. Clutch control, therefore, is tricky and requires the clutch pedal and seat to be ideally set for easy operation. I can do it, but have to work out a way to do things without movement of the left ankle.

With this in mind, the Dexta’s seating position and distance between seat and pedal did not help. The photos you will see provide an idea of how the problem was overcome, but I must take the credit for coming up with the idea for a hand-operated clutch! However, I can’t take the credit for turning that idea into reality, as Ian Linch – a name familiar to regular readers – was the man who agreed to undertake that particular challenge, but more on that later.

With the help of friend and local farmer David Clements, who kindly agreed to help me move and store the tractor, as well as source parts, the Dexta started to take shape. David helped me remove the ROPS, which was no longer fit for purpose, and change the track width from its maximum setting – which had been used to accommodate wide vegetable beds.

New liners are pressed into the block.

Sitting comfortably

The tractor was fitted with row-crop rear wheels and, as I was unable to locate the original rims, I was forced to purchase new ones, together with tyres and tubes.

As the rims, purchased from Agriline Products, were finished in grey primer, I bought some Fordson orange paint from Ernest Doe Power at Sutton-at-Hone and brushed the new colour onto the brand-new rims. I also decided that it would be advantageous to buy new nuts and bolts to fit the rims to the centres, too.

With the wheels on and at a more sensible track width, the first job was to get the seat in a position that would be ideal for someone with a 6ft 1in frame to operate the tractor comfortably. It appears that farmers were expected to be 5ft 9in tall in the 1950s, and so a steel extension piece was added to enable the seat to be positioned further back than the original factory position, along with a length of box section to raise the seat, too.

The clutch, thankfully, was in good order – evidently having been overhauled shortly before the tractor came to the end of its working life.

The seat, a reproduction item purchased from Agriline, fitted the bill nicely but, to further improve comfort, I added an embroidered seat cushion to my basket, courtesy of my wife, Sue. This makes a massive difference to your posture and comfort and, if you don’t have one, I recommend that you get one – you won’t regret it!

With the gap between the seat and steering wheel extended, I could mount and alight the Dexta with greater ease and the lack of agility brought about by a prosthetic leg began to fade too, which was great. At this point it was over to Ian to work his magic on the tractor – getting it to an acceptable standard for me to use and enjoy.

“When Gary first talked about the Dexta that he’d driven as a boy, I was expecting to see a well-used tractor,” he said. “My expectations weren’t far wrong! The Dexta was in a very sad state, and hadn’t been used for at least 10 years. However, because it had been stored in a barn, it hadn’t deteriorated more than I had imagined.

“I believe the tractor was preserved by the amount of oil and grease that it was covered in! The actual tinwork wasn’t bad at all, apart from a little rust here and there. The proof meter (tachometer) had stopped at around 8,000 hours but, at a guess, we both decided it had done approximately 10,000 hours. I managed to repair and get the tachometer to work again.

“The hydraulic arms were seized and stuck in the up position, but I decided to concentrate on the engine first,” Ian explained. “It was a non-runner, so it was decided that I would completely rebuild the engine. Once I got the engine running I could check the gearbox and the back end, so that I could see if the hydraulics would work.”

Pump overhaul

“With a new cylinder head fitted, from Bepco, and the engine completely rebuilt with an overhaul kit, I was keen to see how it would perform – but the bad news was that the injector pump was causing a misfire on one cylinder. So, having checked that the three injectors were not the cause of the problem, we decided to have a full service on the pump itself.”

A prosthetic leg prompted Gary to task Ian Linch with fitting a hand-operated clutch (inset).

The tractor now runs much better than it ever has, with no hunting once warm. I asked Ian if he thought that things had been missed when the pump had been overhauled before, or if other undiagnosed problems had caused the engine not to run as was intended.

“I think it might have been a combination of several things – ie the timing being slightly out as well as the spill timing being out,” Ian said. “Then the diaphragm sticking, or the butterfly in the inlet manifold sticking, or possibly even being a split or leakage in the suction pipe. It could have been several of these things, or a combination of many. Sometimes they hunt for a short while if they are started from cold then often settle down very quickly once the engine warms up.”

Irrespective of the past problem(s), it was nice to hear the tractor running well and I was excited for the next phase of Ian’s overhaul of the Dexta – which was to investigate the hydraulic system and ascertain why the lower links were stuck in the raised position.

“With the help of a heavy hammer, I managed to unseize the arms,” Ian explained. “This also helped to give the unloading valve a wake-up call, which seemed to work. With the hydraulics now working, it was time to attach a heavy implement to the tractor to see if the system worked efficiently. To my surprise, the draft and position control worked well, so there was no further work needed to be done there, apart from the fitting of new weld-on ball ends to the lower links.

“Thankfully, I didn’t come across too many surprises with this tractor, considering its age. However, the nice surprise was that the clutch had been replaced prior to the tractor being left redundant in the barn. The good thing was that most of the tractor was actually complete, apart from a few parts missing here and there.

A new seat and cushion, a birthday gift from Gary’s wife, Sue, were fitted to improve operator comfort.

“I have suggested to Gary that now the tractor is working well it would be prudent to service the engine after about 10 to 20 hours’ work. I would also suggest a re-tighten of the head bolts at about 100 hours and to reset the tappets. If he wants to keep the tractor in its original condition, I would suggest coating it with a spray of wax oil or something similar.”

As well as enabling me to have a tractor that was going to be safe and reliable, the other main point of entrusting Ian with the Dexta was to fabricate a hand-operated clutch – which works very well from my perspective. The operation does require your left arm to be quite strong, making you realise how powerful your legs are when pressing the clutch and brakes, and the extra strength required means that one’s ability to operate the clutch smoothly is tested!

Challenge

Once used to the system it becomes normal and I’d like to thank Ian for making a great job of it. As well fabricating the mechanism, he also added a guard to prevent the lever from being kicked – preventing potential damage to both mechanism and foot!

“Replacing the clutch pedal with a hand-operated clutch was a new and exciting challenge for me, as I hadn’t done anything like this before,” he said. “It certainly wasn’t a major problem, as I had all the right tools at hand, including a lathe which I used to make a bush to go on the bottom of the new hand clutch lever, which I had prepared earlier.

“I didn’t want to cut or adapt the foot pedal in case Gary ever wanted to put it back to how it was. Calculating the free play on the lever was a bit tricky because the lever was quite a bit longer than the clutch pedal. The clutch has to have 1¼in of free movement, or play, before the clutch can disengage. Once I had overcome this problem it worked very well indeed.”

Gary intends to try his hand at match ploughing.

With the tractor fit for me to operate comfortably, I used it for chain harrowing a horse paddock and have purchased a Ferguson two-furrow plough with the aim of entering a ploughing match. I have tried the plough, which went well, but the right-hand drop arm and levelling box assembly were worn and would not allow any adjustment.

I bought a new one from Agriline, together with a Fordson blue aerosol to make the finish a bit more original, and this doesn’t leave much left to do to the tractor. As things stand, the only outstanding fix left for now is to fit a new PTO seal, as this leaks, and the steering box will need some attention too, thanks to 60-plus years’ use, but I am happy to leave that for now.

A point worth noting is that this tractor does have a very high top gear. Mr French told me that it was capable of 24mph – just shy of 40kph – and could easily outrun the farm’s Ford 4000s. Having researched this point, it seems that some Dextas were fitted with ‘high speed’ transmissions and I can assure you that it’s a good test for the brakes when towing a trailer at this speed!

I am indebted to Ian for fitting the hand clutch to allow me to safely drive the tractor after all these years. The Dexta and I are both showing our respected ages, but with the tractor now almost back to its best we can continue our journey together once more!

This article is from the latest edition of Tractor & Machinery magazine. For a money-saving subscription, simply click HERE