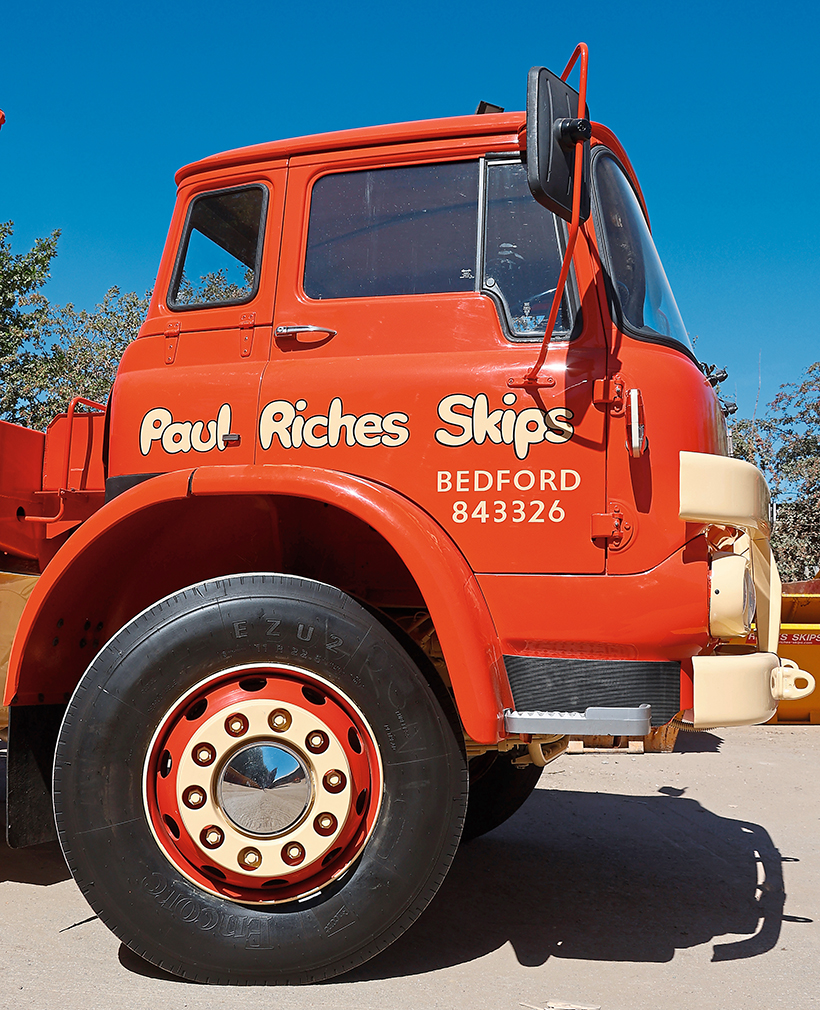

1976 Bedford KM skip lorry beautifully restored

Posted by Chris Graham on 19th January 2023

Ian Shaw tells the story of Paul Riches Skips’ restoration of its very first, 1976 Bedford KM, which arrived with the company back in 1985.

Paul Riches’ 1976 Bedford KM skip carrier has been beautifully restored.

Traditionally, Bedfords were lightweight commercials; in fact, that was in many respects the brand’s Unique Selling Point. However, the KM was a totally different animal and hailed a new direction of travel for the marque. Launched at the 1966 Commercial Vehicle Show, the KM – despite sporting a (slight) variation on the TK cab – was built upon a much bigger chassis with a more muscular drivetrain, and took the company straight into the lucrative 16-ton marketplace.

Initially the KM was offered in three wheelbase lengths for general haulage work, a further three for tipper applications and two more as tractive units for 22-ton gross weight operation. Axle capacity was rated purely to the gross weight, with six tons on the front and 10 at the rear. As a chassis-cab, the new KM tipped the scales at 4.4 tons.

The Bedford was a little worse for wear, to put it mildly…

The whole new truck was given a whole new engine, too. The Bedford 70 Series; a six-cylinder diesel with a seven-bearing crank, displacing 7.63 litres and developing 136hp at 2,800rpm, with a maximum torque of 320lb/ft at 1,600rpm. A choice of two five-speed Turner transmissions was offered. Both had synchromesh on the upper four gears with one having a direct-drive fifth and the optional unit providing a 0.836:1 overdrive ratio. Strangely, rather than having a sixth ratio as overdrive, or creating slightly increased steps between the intermediate ratios to spread the cascade, the overdrive version had a much higher first gear, to maintain the same rpm decay throughout the gearshifts. In effect it was designed from top gear, downwards. Consequently, many operators also specified the optional two-speed rear axle.

… when Paul started the restoration.

The KM’s suspension had a mixed on/off highway specification, with eight-leaf springs on the front axle and seven (slipper-end) main leaves aided by seven floating helper leaves at the rear, with rubber-bushed eyes all round. Bedford clearly knew the tipper sector well. The brakes were also particularly noteworthy. A dual-air system, with twin reservoirs making the secondary braking system a complete duplication of the service brakes. This was claimed as an industry-first by Bedford at launch. The front brakes were much larger than was normal at the time being 7in wide by 15½in diameter, and 8in x 15½in at the rear. This gave a 16-ton KM over 900sq/in of friction material in total.

The original cab was found to be in a very sorry state, once removed.

The brakes themselves were Girling wedge-operated, twin-leading-shoe units, while the wheel actuators were the highly-respected Clayton Dewandre piston/diaphragm units with the diaphragms used for the service brakes and the pistons for the secondary system. Air-assistance was given to the application of the handbrake too, provided by a linkage from the actuator pistons at the rear axle. Power steering – by Burman – was standard at a time when most other manufacturers were still showing it as an extra-cost option.

The modified TK cab provided plenty of space for its day, while the KM boasted a Bostrom hydraulically-sprung driver’s seat, a second mirror on the offside – giving a wider angle of view – and windscreen washers were standard. Larger tyres compared to a TK meant that the cab step had increased to 2ft.4in off the road, with the floor of the cab itself being 3ft 6in above ground – but still about 2ft less than that of a top-flight 44-tonner today! There was still, though, no tilt-cab – something most rivals were now including, and Bedford dealers still had to recruit fitters with one arm five feet long and nine fingers on the other to access the greasy bits via flaps at the rear.

The ex-military cab in sound condition was used as a replacement.

Worked before preservation

The KM featured here is a 1976 148in wheelbase skip carrier and essentially the same specification as the mid-range KM tipper. It’s owned by Paul Riches, managing director of Paul Riches Skips. It was owned from new by EC Smith & Sons who ran it until 1985, when Paul Riches acquired it as his first lorry. The KM was by this point in need of some renovation work, but Paul was able to keep it running for two years as his sole vehicle until the business was established, at which point the KM was taken off the road. However, building the business was very much Paul’s priority so, while full restoration was always envisaged – and there was never any question of selling the lorry that had started the business – work didn’t actually start until 2010.

The cab, unfortunately, was too far gone to repair but, with LW Vass just down the road, sourcing a replacement ex-military (MK) cab was the obvious solution. Though the replacement cab was sound, a few modifications were needed as the MK had no power steering and the steering box and column mounts had to be swapped over.

The replacement cab all ready, primed and awaiting top colour.

By contrast, the KM’s mechanicals were basically sound and, having worked with the lorry for two years, Paul knew his way around it, and all about what had been done recently.

The chassis was stripped, the engine removed and all the air pipes and tanks – which were found to be totally rotten – were renewed. During its working life the KM had had two replacement engines, and the one fitted was refurbished, with work including all new gaskets, a replacement sump pan, the rocker cover and a replacement injection pump along with a set of injectors. A reconditioned starter motor and alternator sorted the electrics while a reconditioned radiator was added before a full engine and ancillaries re-paint.

Owner Paul Riches and his first skip truck, which he keeps clean these days.

As usual with restorations, Paul had help, and he’s quick to acknowledge all the people who played a part. His grandson, Steven Richards, was on hand to help with the engine removal while the late Mick Davies, carried out much of the mechanical work. Welder and mechanic Roger Wehrstedt formerly of London Brick, and ex-Renault Trucks fabricator and welder Andy Vine took on the chassis work, along with Ainsley Petty and Norman Joiner who originally trained at LW Vass, the suppliers of the ex-army cab.

The KM was then sent to Webb in Suffolk for the skip-loader equipment, body and hydraulics to be completed before heading to the paint shop. After six years – in 2016 – it emerged resplendent in the Paul Riches Skips’ original livery, to begin its new life as a show truck and advertisement for the company.

On the road, the Bedford keeps pace with modern traffic.

And an Alpha

These days, the Paul Riches fleet numbers 14 lorries, all of which are bought outright rather than leased, and operated over a 20-year working life. Most are DAFs, along with a single Volvo and MAN and a Cummins-engined Foden Alpha which was bought new in 2006 and, freshly painted, still sees daily duty. A second Foden Alpha two-axle rigid is used as a yard shunter. The rest of the fleet is more recent and split between 11 two-axle skip carriers; one MAN, with the rest being DAFs. There are also three eight-wheelers consisting of two DAFs with ro-ro bodies and one Volvo tipper and grab.

The spacious cab – thanks to rearward positioning of engine – offers excellent vision.

Since its beginnings, Paul Riches Skips has seen the waste management industry go through something of a revolution. Its primary purpose used to be disposal, now its goal is recycling and the company has been averaging this 90% recycling and just 10% to landfill for several years. Waste comes from commercial domestic sources. “The four-wheelers handle most of the smaller-sized skips from Joe Public,” says Paul Riches, which is mainly soil and hardcore collections, with the ro-ro-bodied eight-wheelers and the grab/tipper taking care of industrial materials and scrap metals. Thirty-one people work here; 16 drivers and another 15 who operate the recycling plant. This includes sifting and sorting through building waste – often by hand – as landfill will only accept soil and must not contain any rubble. Machines here include wheeled loaders from a small Bobcat to articulating Volvo shovels which are assisted by several tracked excavator and grab machines for the scrap metals handling.

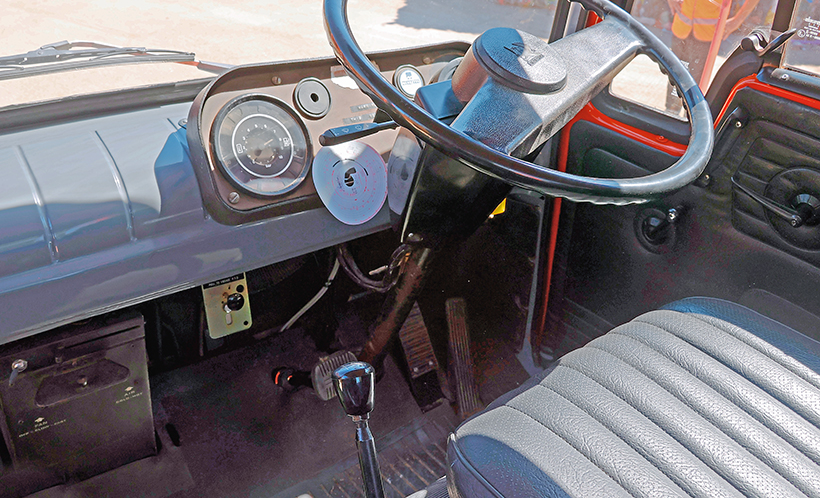

TK-derived cab is higher, with the air-operated park brake dominating the entry point.

Alongside all this modern kit it’s actually quite surprising how modern the KM looks. The Bedford’s double front bumpers and quad headlamps give it a much more heavy-duty, almost aggressive frontal mask; a contrast to the rather mild-looking TK. Hard to believe the cabs are otherwise virtually identical. The business-end, boasts a Telehoist Load Lugger skip loader rated at some 16 tons – the vehicle’s GVW – so they obviously expected a bit of overloading.

A Bedford in Bedford; how fitting!

Before the days of on-board weighing, skip lorries were more prone to overloading than tippers. At least the JCB driver could estimate the tonnage from umpteen buckets of soil but, with a skip, who knows what’s lurking beneath the top layer? The one-piece lifting arms look long compared to the retracted extending lifting frames on the more modern occupants of Riches’ yard, but there’s a simplicity to the KM’s gear. It makes one ponder the need for more hydraulic rams, more controls and more complications to hoist a skip on board. The cab is wonderfully original also, it’s all been re-trimmed but it is period-correct and looks factory-fresh.

Lovely details abound on this restoration.

Out on the road it sounds just right, too. Unladen, it bounds along quite happily with modern traffic and draws attention from truck drivers in the latest Scandinavian 44-tonne ‘spaceships’. Before ‘Hi-Vis’ entered everyday vocabulary, a bright orange truck was just what you needed, trundling around grey and drizzly landfill sites populated by massive D9 ‘dozers and articulating dumpers. Thankfully, the KM is spared such indignities these days and spends its time on the show circuit with the sort of success you might expect from such a fine restoration.

The six-ton front axle features big brakes and generous tyres.

It’s no local carnival queen, however, and Paul recently did a Yorkshire road run with his beloved KM, from its Bedfordshire base, through Lincolnshire and a loop around North Yorkshire; a round trip of over 300 miles. Not many current skip lorries see that sort of radius from the yard. After the KM, Bedford was on a roll, moving into the 1980s with the TM, a different kettle of fish completely but, despite its much more class-competitive cab, modern looks and use of the quirky Detroit two-stroke diesel, it never quite managed to do what the KM had done.

Bedford’s (poor) substitute to designing a tilt-cab for its all-new truck.

The author wishes to thank owner Paul Riches, transport manager Simon Arnold and all at Paul Riches Skips.

This feature comes from the latest issue of Classic & Vintage Commercials, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

Very rare JF Coates stationary engine saved!

Next Post

Sentinel steam waggons on a run down memory lane!