Beautifully-restored 1967 Massey Ferguson 165

Posted by Chris Graham on 23rd November 2022

Chris Graham meets Richard Collishaw and his recently-restored 1967 Massey Ferguson 165 that’s been on the family farm since the late 1960s.

Richard Collishaw’s now immaculate Massey Ferguson 165 was restored two years ago, but has been on the family farm since it was bought new by his father in the late 1960s. Amazingly, it continued working right up until 2015.

It’s a popular belief that there’s no place for sentimentality in farming nowadays but, thankfully, many of those involved with classic and vintage tractors are bucking that trend. Richard Collishaw, who farms with a 260-strong herd of pedigree Holstein Friesian dairy cattle, is a perfect case in point.

“I have a very strong attachment to my 1967 MF 165,” he explained. “It was the farm’s main tractor back in my father’s day and, while other models have come and gone over the intervening years, that one has thankfully survived. Now, following a full restoration, I’m happy to report that it’s better than ever.”

Richard is delighted to have been responsible for returning the tractor to ‘as new’ condition, and now gets immense pleasure from driving it, just as he did when he was a boy.

Happy memories

The MF 165 Multi-Power arrived on the Collishaw’s dairy farm as a brand new tractor from Chandlers of Grantham, as the 1960s were drawing to a close. “I have many happy childhood memories of driving that tractor around the farm, and still have a photograph I took with my Kodak Instamatic of my father on it soon after we got it,” Richard told me. “It was the main tractor in those days, and proved to be a very useful machine for many, many years. Before that, my father had run a Grey Fergie and then an MF 135 Multi-Power, although both got moved on as they became too small for our needs. Incidentally, I know that both machines survive today, as they’re listed with the DVLA, and I’d love to find them.

“When I was 16 years old and ready to take my tractor test for road driving, I did that on the 135. I’d driven it and the 165 a lot on the farm by that stage but, for whatever reason, I took the test on the 135. This was back in 1975 and, as I remember, the test was simplicity itself. An official examiner visited us here at the farm and, while he stood at the roadside, all I had to do was drive the tractor down the village high street, turn around and drive it back, and that was it. The whole thing took about five minutes!

Richard’s father at the wheel of the MF 165, soon after it arrived on the Collishaw’s dairy farm. This photograph was taken by Richard, using a Kodak Instamatic, when he was about seven years old.

“The MF 165 certainly worked hard on the farm, and was fitted with a front loader and a non-Massey Ferguson power steering system at one stage. Then, in 1976, we had to add a Sekura cab, and this was one of the first jobs that my brother and I did on it once we’d started working full time on the farm. This was done to meet safety regulations, and I well remember how much noisier it made the tractor to use. Latterly, as the operation progressed and grew, the old 165 was demoted to yard-scraper duties but, amazingly, it kept working for us right up until 2015, when disaster struck.”

A grinding halt!

“As well as operating as a scraper, the 165 also performed other basic duties around the yard, including providing power for the slurry stirrer. It had to be parked on a slope to do this and, on one occasion, this incline evidently highlighted a lack of oil in the engine, caused lubricant starvation and led to the motor seizing solid.

“That was certainly a sad day but, as we towed the stricken machine into a nearby shed, there were still no thoughts of scrapping the tractor. I think we all had too much of a connection with it to see it leave the farm and, for the next few years, it simply sat, neglected in the shed.

The 165 in pre-restoration condition, still with the Sekura cab in place, which Richard and his brother fitted in 1976. Incidentally, this cab is now for sale (complete with its doors) so, if you’re interested, give Richard a call on 07800 828602.

“For quite a while, people who knew about it had been advising me to either sell the MF 165 or get it restored so, eventually, I decided on the latter. Clearly the tractor’s down-at-heel condition meant that it was only heading in one direction if left as it was, so I decided to get something done about it.”

According to Richard: “The restoration work started about two years ago and, altogether, took about seven months to complete. I began by removing the cab and was then very fortunate to find the perfect man to take care of the restoration. I wanted somebody I could trust with the project and Alan Faulks certainly fitted that bill. He lives locally to me and I’ve known him and his family for 40 years. He trained as a fitter on 1960s and ‘70s Massey Ferguson tractors and, in my opinion, has a level of practical knowledge and experience that’s unmatched. I also liked the fact that he operates on his own, so I had complete confidence in his ability to tackle the job.”

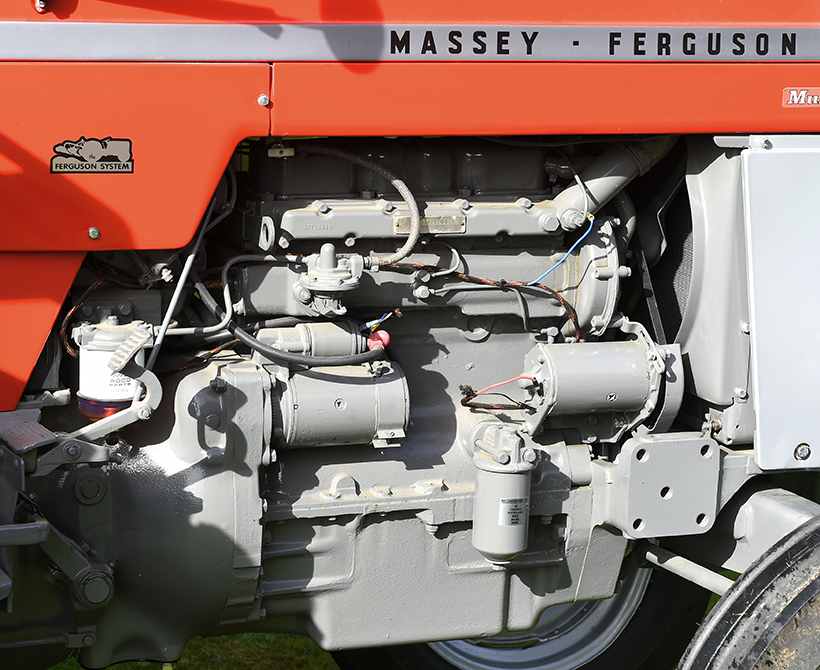

The skid unit was sprayed in Stoneleigh Grey by experienced Massey Ferguson restoration expert, Alan Faulks.

Restoration begins

“Once I’d delivered the tractor to his workshop, I was amazed by how quickly he got cracking. I returned just a day or two later and found my tractor in what appeared to be thousands of pieces, all over the workshop floor! I’m such an admirer of Alan’s skill, and it wouldn’t surprise me to discover that he was able to tackle everything without the need to refer to a single manual.

“The seized engine was sent away to a specialist engineering firm in Loughborough called CCP Diesels and, fortunately, the subsequent strip-down revealed that the level of internal damage wasn’t too great. Getting the crankshaft re-ground then fitting new pistons, bearings and cylinder liners, plus skimming the head, was pretty much all that was required.

“As far as I’m aware, the engine had never needed any major repairs during its working life; apart from a replacement head gasket, a de-coke and tappet adjustment from time to time, it was as good as gold. The head was left intact and everything else was reassembled without a single hitch.

The rebuild continues, with the freshly painted red tinwork back in place.

“Alan found nothing wrong with the Multi-Power transmission so, apart from changing the oil, he left that side of things well alone. The brakes were stripped and rebuilt with new linings and that really was about it, from a mechanical point of view. Once rebuilt, Alan sprayed the skid unit in Stoneleigh Grey, but sent the original tinwork away to Ben Craig – an agricultural engineer and restoration specialist based in Harby, Leicestershire – who has the specialist equipment and facilities needed to apply the red, two-pack paint I’d opted for.”

Although the tractor had been on the farm from new, it had led a hard working life and there were a number of original components that had got damaged or gone missing over the years. Consequently, replacements were required, as Richard explains. “The original 19in front wheels had been changed for smaller, 16in rims when the front loader was fitted. Then, subsequently, one of the original rims got lost, so I opted to buy a replacement pair of period 19s from Pocock Tractor Supplies Ltd in Dorset, which are fitted to the tractor now.”

When not on road runs or at shows, the 165 now lives in its own shed which also houses the farm’s standby generator, positioned to be driven by the tractor’s PTO in the event of a power cut.

Wheels and trim

He continued: “One of the rear wheel rims had become badly corroded back in the day, and had been replaced singly at the time, leaving an odd pairing on the tractor as a make-do-and-mend measure. Obviously, though, I wanted to find a matched pair to fit to the restored machine, and managed to locate of a pair of period, 36in rims in good condition. All four wheels were then blasted and painted, before being fitted with a new, original-specification tyres.

“Another component that had seen better days was the driver’s seat, which was quite badly holed, where water had obviously collected in the past. So, I opted to swap that with a very good replacement that I found online. However, I’ve saved both the old seat and the one original front wheel, and put them together to make a unique chair which I keep in the garden room; so the pair have been ‘reimagined’, and live on in a different form!

Fortunately, internal damage caused by the engine seizure was relatively straightforward to put right. Now it starts on the button, doesn’t smoke and runs reliably, much to Richard’s delight.

“The old plough lamp was missing (they are prone to both rusting and damage) so was replaced with a good-condition original that I found on eBay. Also, another important, original-spec component that had got lost was the Wingard mirror. I remember that it had to be removed when we fitted the cab, after which it was hung on a nail in one of the sheds, where it stayed for many years. Sadly, though, it didn’t survive, but I was able to replace it with a similarly-aged example found on eBay.

“The headlights are original, although they sit on a replacement grille. I used the original Instamatic photograph as a reference for the positioning of the decals; the ‘Multi-Power’ ones were carefully placed, and I also made sure that the reproductions I used had the correct lettering typeface – I’ve seen some that are wrong in this respect.”

A number of components had been lost over the years, including the original mirror that was removed when the cab was fitted. Richard found this authentic replacement online.

The finished result

Richard is understandably very pleased with the way things have turned out. “Not only am I delighted with the final finish but, having a usable classic tractor has opened-up the world of road runs and agricultural shows to me, which has been a significant, and very pleasurable bonus.

“The restored tractor has certainly lived up to every expectation I had for it. I drove it home from Alan’s workshop on a lovely summer’s evening in 2021 and my wife was simply amazed at the transformation. We haven’t looked back since. I’ve attended a few local shows, and taken it on three or four road runs organised by the Vale of Belvoir Machinery Group, which is a strong and enthusiastic group based in Harby, Leicestershire.

The hydraulics are fully functional, the brakes have been relined and new tyres were fitted all round.

“The first tractor run happened less than a week after the restoration was completed, but I had no qualms about entering. It ran faultlessly and caused quite a stir as I was a new member and nobody had seen the tractor before, so that was great. I’ve also exhibited it at three shows, the first of which was the 2021 Southwell Ploughing Match & Show, in Nottinghamshire. I drove the 20 or so miles each way to that event, and won third prize in the static tractor class, which was amazing. Then, this September, I drove it to the Flintham Show and won first prize! I returned to the Southwell show this year, too, but didn’t manage a rosette this time. I’m now starting to think about sorting out an implement to mount on the back, to give the tractor even more appeal at shows.

“Sadly, this farm has sold and/or scrapped far too many pieces of interesting equipment over the years, but it’s easy to regret such actions with the benefit of hindsight. At the time, when equipment breaks or lets you down – typically when it’s needed most – alternatives have to be found. All I have left that might fit the bill is a late 1950s Vicon Acrobat hay turner and, although its perhaps a little small for the 165 and would look better on a 135, I may pursue that idea.

The headlights and their housings are original, although they’re sitting on a new radiator grille assembly. For the future, Richard is considering having the exhaust sprayed white.

“I’m not keen to work the tractor – it’s done its time, after all – so don’t plan to get involved in competition ploughing or cultivation days. However, one of the justifications for the whole project was that the 58hp 165 could be used to power the farm’s standby generator. We’ve used it in the past for that job, so I’m confident that it’ll be perfectly capable of doing the same now. So much so, in fact, that I’ve built a dedicated generator shed/tractor storage unit next to the house, where the 165 sits connected – via its PTO – to our 44kVA generator. This has a large enough output to run the farm’s milking machinery, water heater, milk refrigeration unit, automatic slurry scrapers as well as provide an electrical supply for our house.

“Of course, little did I know how things would turn out when I first thought of that plan a couple of years ago. Now, with the prospect of power cuts looking like a real possibility over the coming winter, this set-up could really come into its own and the 165 will, once again, be performing essential work for the farm.”

CAN YOU HELP?

Richard would love to track down a couple of his family’s previously-owned tractors that he knows still survive. The first is a 1967 MF 135 Multi-Power that’s registered MNR 729F, and it was traded-in at Tractamotors in Melton Mowbray, when it became too small for the farm’s needs.

This is the unusual chair that Richard made using the MF 165’s one remaining original front wheel, and the tractor’s seat that his father used for so many years.

The second machine he’d love to find is a 1955 Ferguson TE-20 four-cylinder diesel, with the registered MNR 701. Any help would be much appreciated. If you have any information, please email the Editor, or call Richard direct on 07800 828602.

This feature comes from the latest issue of Classic Massey & Ferguson Enthusiast, and you can get a money-saving subscription to this magazine simply by clicking HERE