Beautifully-restored 1985 Volvo F7

Posted by Chris Graham on 2nd January 2023

Peter Simpson and Alan Turner tell to story of Richard Turner’s 1985 Volvo F7, and the tractor unit’s full restoration.

Richard Turner’s 1985 Volvo F7.

Back in the mid-1980s as a young lad, East Yorkshire-based Richard Turner was fascinated by lorries, and living where he did, was able to observe many different types and sizes on local agricultural-based work and more long-distance stuff. One, however, made a special impression on him. 1985 Volvo F7 B707YAG was operated by Market Weighton-based J Dawson & Sons, used mainly with a bulker trailer on corn transport. Back then it was very much a modern, state-of-the-art vehicle, and young Richard would often watch it coming out of Dawson’s yard from his bicycle.

Fast-forward a few years and Richard not only retained his interest, but also become involved professionally, working as a commercial vehicle fitter for local repair specialists Charlotte Bradley Transport. The F7, too, had moved on, but like Richard, it had stayed local, passing first to Mick Jackson, a localagricultural equipment dealer who used it with a low-loader. From here, it passed to local enthusiast Noel Stephenson who intended to restore it and got as far as sourcing some hard-to-find parts – including a pair of new doors – to use in the restoration. However as is so often the case life got in the way, work never got started, and the F7 ended up being parked up “behind a shed” for around 20 years.

The Volvo while in service with Dawsons and looking almost identical to how it is now.

At this point Richard was unaware that the F7 still existed, even though it hadn’t gone far. The tipoff came from a friend at work, James Stott, who knew of the Volvo’s existence and who owned it. Anyway, the subject came up in conversation in 2018, and it turned out that Richard had known Noel in the past. So the inevitable happened, a deal was agreed, and James Stott duly collected the Volvo using a low-loader. Unsurprisingly, it was in quite a state…

At this point we need to bring someone else into the story; Richard’s dad Alan. Alan, along with James Stott, did the bulk of the restoration work, with the job taking around three years to complete. In fact, we’re going to let Alan take over the narrative now, and tell the rest of the story in his own words.

As bought by Richard. Previous owner Noel had obtained and fitted new door skins.

The restoration

“Do you want to work on this Volvo F7?” Richard asked me one day. “Not Particularly, why?” “Because I haven’t time to do it.” That was how it all started. At this point it had already been over to Britcom where the chassis had been short-blasted and painted. But as for the rest; well I made an assessment of what was needed and made a decision: I still don’t want to do it. However, in the end lunacy prevailed and I was persuaded to embark on a more than two year restoration project. Richard had picked a good time to ask me, as for the previous eleven years I had been a permanent way volunteer on the North Yorkshire Moors Railway, but having turned 70 I was starting to find railway sleepers and rail chairs a lot heavier than they had been when I started.

The much worse spares donor vehicle. The remains of this may now be available to help with another restoration.

I began by looking at the cab floor – or what was left of it! Both outer floors looked rather delicate, with the underside reinforcements having the strength and thickness of potato crisps, and the seats well on their way to breaking right through! Many measurements were made before deciding how much floor to cut out. Eventually we decided that most of it would have to be renewed, and all-new parts and reinforcements were made up and welded into place by the “brilliant” James Stott. Most of the nearside top corner where the front door pillar meets the roof also had to be renewed, along with a good length of the same door pillar in the top hinge area.

Starting to probe for rot. As you can see, not a lot was suitable to ‘leave’ and virtually nothing of the support members remained. This is the nearside cab floor.

We were fortunate in being able to find a spares lorry early on which, though much too far gone to be restored in its own right, was good in many ways that ours wasn’t, and was thus able to donate many useful spares. These included the vent sections on the back of the cab, where the plastic louvres fitted the apertures, and instead of making complicated repairs we were able to simply cut the sections from the donor cab and weld them into the ‘patient’.

The offside cab floor, seen here after all the rot had been cut out, was even worse than the nearside.

Another common and hard-to-repair rot spot on these cabs is the lower windscreen aperture. Repairs here have to be spot-on for the screen to fit correctly and be watertight, and again the rotten-out area was cut out completely and replaced with new metal. New front splash guards (in front of the wheels) were also made, along with replacements for the nearside top wing and the front mudguards behind the front wheels. Fortunately, we had in stock a new offside front top wing, but many other, localised areas of rot had to be cut out and fresh metal let in. Volvo cabs of this era were never massively rot-proof in later life anyway, and standing outside out of use for two decades certainly didn’t help this one.

Offside floor edge repaired, with the new support sections.

One further problem emerged when we were bolting everything together; we wanted to renew the beading between the cab and wings, but despite our best efforts we were unable to source any. Fortunately, by careful and painstaking cleaning and rust-removal, we were able to bring the originals back to acceptable condition. That completed the cab, but one further fabrication job was required; the lorry came with a set of new rear mudguard stays, but these turned out to have been made incorrectly, and a new set had to be made.

The lower sections were, as usual, very bad with the wing and step sections all needing significant repair.

With the cab welding completed, the part-finished lorry went, again, to Britcom Commercials paintshop in Market Weighton where it was refinished in the original green livery under the expert eye and supervision of Fran Johnson. Fran was certainly the right person to do this as back in the mid-1980s, while working for Pocklington Coachworks, he had painted this actual lorry for J Dawson & Sons when it was new! The supplying dealer, incidentally, was Crossroads Truck & Bus of Hull.

Cab repair well underway, with most original paint removed back to bare metal.

Mechanical maladies

So, with the cab and chassis finally complete, there remained the somewhat daunting task of making a lorry that had been off the road for 20 years roadworthy again. Here the donor lorry really came into its own when it came to replacing stuff that was either missing or beyond repair/refurbishment. One very pleasant surprise-find on the donor was an almost-new refurbished radiator. This went straight on to the project lorry. Also reused was the steering box, as the original had a badly-leaking top seal, renewal of which will involve a major strip and rebuild. It had been noticed that the cab wasn’t sitting 100% straight, so all the mountings were transferred from the donor. This was a rather awkward and precarious job, and we removed the old ones by suspending the donor cab from the shed roof. Last time I looked it was still there…

Elsewhere the cab also needed significant amounts of work.

When it came to sourcing other stuff we had to search worldwide, and here Richard’s son Joe and his computer skills were a great help. One noteworthy find was some new brake backplates in Morocco! Brake drums and shoes were also renewed, along with the brake foot valve and various steering joints including a drag link and track-rod ends. A new set of Bridgestone tyres came from DMP Tyres’ Market Weighton branch, and a replacement alternator went on as although the original worked, the noise from its bearings was deafening!

Interior refit underway. The headlining refurb and refit was, as is usual, the hardest part.

We had a few problems with the cab interior; specifically the headlining which, as we discovered when we tried to do it, should really go in before a windscreen is fitted. However as fitting the screen had taken us ages, I vetoed Richard’s suggestion that we take it out again! On our lining, the front corners were shot due to water ingress from the leaking cab top, but those on the donor were good. By contrast though, the back of the original lining was better than the original. So we cut both in slightly over half and joined the two good sections with a slight overlap which we figured would be covered by the curtain rail for the sleeper. The two halves were then sent to Dawson Upholstery who are based near Malton. When they came back, the two halves were put into place via the nearside door with Richard, his mother Ann, his eldest daughter Jess and myself all clinging to and pushing/pulling various pieces inside and outside of the cab. Eventually it all went into place as intended, and the join isn’t at all obvious unless you know. With that done, the rest of the cab interior could be built back up.

Sign-writing, done the old-fashioned way.

Engine-wise it was the usual service and clean up, though the air cleaner casing was rebuilt pretty-much from scratch and a new oil filler pipe was made. A set of rebuilt injectors also went in, along with the usual new filters and drivebelts. When the engine was starred for the first time an oil leak from the sump to block joint was apparent, but this was cured by straightening the mounting flange carefully and fitting a new gasket. In view of the long time out of use, the engine oil and filters were changed three times in the first year. The gearbox and rear axle oils were also changed along with the rear axle oil seals, but no other work was needed here. Shortly after returning the engine to running order the silencer decided to blow itself apart and need re-skinning.

Back from painting, and starting to come back together.

One part of the job which we still aren’t quite sure about is the rear light arrangement; if there was ever a factory-original arrangement here we’ve not been able to find it as though we’ve seen numerous preserved examples in photos and the flesh, we haven’t yet seen an original one. What we have done is therefore a best guess as to how it should be. The sign-writing was done by Laurie Nicholson and will almost certainly be his last professional job after a lifetime’s work due to age, but the job he did here was absolutely superb.

Finished, and reunited with Colin Head, its main driver when owned by Dawsons.

And really, that’s about it. In conclusion, Richard and I would like to thank the following for their assistance – James Scott and our son/grandson Joe Turner for doing much of the actual work, Fran Johnson and his team at Britcom International for painting it, Laurie Nicholson for sign-writing, Dawson Upholstery for the headlining and DMP Tyres for supplying the tyres.

Alan and Richard Turner, a father-and-son team.

From the rear; the light arrangements may not be correct and the owners would love to see a period photo of what an F7 should look like here. Front and rear numberplates are both original.

Genuine 1980s stickers – one on each side – make a lovely finishing-touch. Alan was given these at a Radio 1 Roadshow back in the day, but they were left in a drawer.

Sleeper cabs are handy when attending two- or three-day shows. This one’s pretty plush, too.

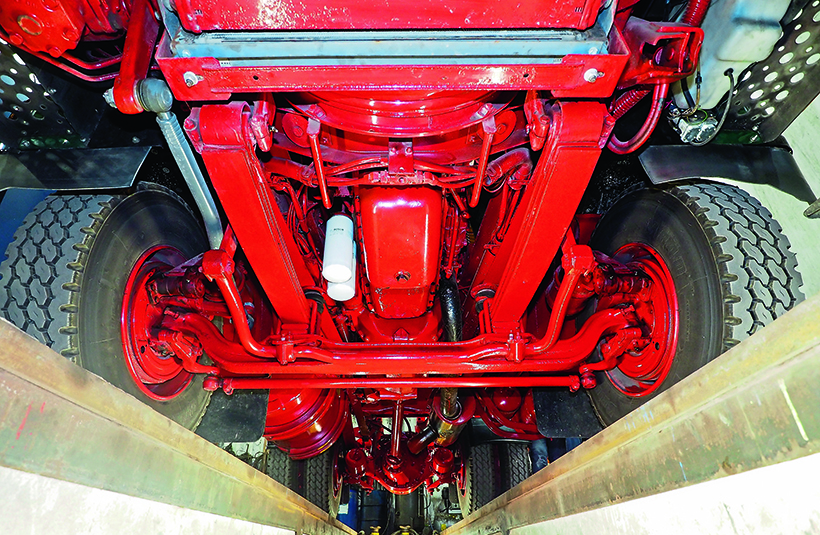

Unusually, we had access to a pit during this photoshoot, so can show you just how fabulous this restoration is underneath.

Fifth wheel’s jaws are among the wearing items that have been replaced with new.

Front panel up for routine maintenance; our Editor recognised the expansion tank cap as identical to the one on his much-loved Volvo 240 estate.

Dashboard and minor controls. No surprise that Volvo trucks quickly found favour with those who drove them!

This feature comes from a recent issue of Classic & Vintage Commercials, and you can get a money-saving subscription to this magazine simply by clicking HERE