This Bedford KM looks as good as new!

Posted by Chris Graham on 17th July 2024

The Bedford KM represented a move into the big league, changing the company’s persona and, for a while at least, its fortunes, says Ian Shaw.

The fully-restored Bedford KM looks like it was built sometime earlier this week!

General Motors initially only assembled trucks in Britain from parts manufactured at its Canadian works, until November 1925 when GM purchased Vauxhall Motors. with production transferred in 1929 to Luton, Vauxhall’s headquarters.

From then on, the vehicles still had something of a trans-Atlantic flavour and this was to set the tone for the early production vehicles. These AC and LQ light vans, produced at Luton dubbed ‘Chevrolet-Bedfords’ were produced from 1929 to 1931 at which point the Chevrolet badge was dropped and the first true Bedford lorry, a two-tonner, was built but visually was almost identical to its LQ predecessor. Its 11-foot wheelbase was joined by a 13-foot derivative and this in turn sired two bus chassis, designated WHB and WLB. All utilised the straight-six OHV petrol engine, so by the early 1930s, Bedford had already set its future path and the light chassis and petrol-engine combination was to live-on, long past its peak.

The KM looked a little worse for wear when Paul took it on.

The three-ton WT series had been introduced in 1933 upon short 9ft 3in and long 13ft 1in wheelbases designated WHT and WLG and these were to be the mainstay of truck production through the 1930s. Mid-1939 saw a complete revamp of Bedfords, with only the HC van continuing in production. The new range consisted of the K (30–40 cwt), MS and ML (2-3 ton), OS and OL (3-4 ton), OS/40 and OL/40 (5 ton) series. Most of its existing vehicle fleet were requisitioned for military use.

As early as 1935, Bedford began the development of a 15 cwt truck for a War Office. requirement. This entered service as the MW in 1939, and 66,000 examples had been built by the end of the war. The MW appeared in a wide range of roles, as a water tanker, general duties truck, personnel carrier, petrol tanker, wireless truck and anti-aircraft gun tractor. The War Office designated 15 cwt vehicles, such as the MW, as trucks, and larger vehicles as lorries.

The 1939 K, M, and O-series lorries were quickly redesigned for military use. This was largely a matter of styling, involving a sloping bonnet with a flat front with headlights incorporated and a crash bar to protect the radiator in a minor collision. The military versions were designated OX and OY series, and again were put to a wide range of tasks, including mobile canteens, tankers, general purpose lorries, and a version with a Tasker semi-trailer used by the Royal Air Force to transport dismantled or damaged aircraft. This variant was popularly known as the Queen Mary. A number of Bedford OXD 1.5 ton chassis were converted to make the Bedford OXA armoured vehicle. A total of 72,380 OY and 24,425 OX lorries were built.

The war-time QL with a forward control cab was a rare cutting-edge design for Bedford whose predominantly bonneted cabs still harked back to the Chevrolets.

KM looked a little worse for wear when Paul took it on.

A further departure being its four-wheel drive transmission entering service in March 1941 with its QL, designation quickly earning it the nickname the ‘Queen Lizzie’. As with the MW and OY / OX models, the QL went on to serve in a large number of roles, such as artillery tractor, command vehicle, wireless lorry and petrol tanker, as well as the troop-carrying QLD, the most common variant.

After the war, Bedford began moving up the weights ladder and the biggest step came in the shape of the S-Type in the 1950s. This brought Bedford into the seven-ton range, with the S being built as both rigid and artic versions with either petrol or diesel engines. although it is best known in its military guise as the RL a four-wheel drive, high ground clearance derivative using a 4.9-litre straight six petrol engine, which in Green Goddess Auxiliary Fire Service guise, was used until 1968, then saw a second life up until 2004 as over 1,000 were held in reserve by the Home Office for use in the event of fire-service industrial action or other serious emergencies. They were disposed of by the Home Office in 2005 becoming something of a collector›s item today.

TK-derived cab is higher with air-operated park brake dominating entry point.

The Bedford TK range began life in 1959, and served as the basis for a variety of derivatives including fire engines, military vehicles, horse-boxes, tippers, flat-bed trucks, and other specialist utility vehicles, whilst the British Army used a four-wheel drive version of the TK called the MK.

Available with four and six-cylinder petrol and diesel engines, the TK was the quintessential light truck in Britain through most of the 1960s and 1970s, competing head-to-head with the Ford D series, but Bedford still needed to hit the big time and the lucrative fleet sector. The new KM was the answer, with a much bigger chassis and drivetrain, it took the company straight into the 16-ton marketplace at the 1966 Commercial Vehicle Show.

Spacious cab thanks to rearward positioning of engine offers excellent vision.

Bedfords were often criticised for their rather ‘light’ build – although in fairness the company’s origins were in light trucks – the KM was a different animal. Bedford used its deepest chassis rails to date. Moving up from 14 tons to 16 may not seem like much of a step, but Bedford’s engineers knew that the higher weight class brought much heavier duty applications, and the KM was essentially a new truck from the ground up, only utilising a (modified) TK cab. It was built in – what was at the time – Europe’s biggest truck factory

Initially, the KM was offered in three wheelbase lengths for general haulage work, a further three for tipper applications and two more as tractive units for 22-ton gross weight operation. Axle capacity was rated purely to the gross weight with six tons on the front and ten at the rear. As a chassis-cab it tipped the scales at 4.4 tons.

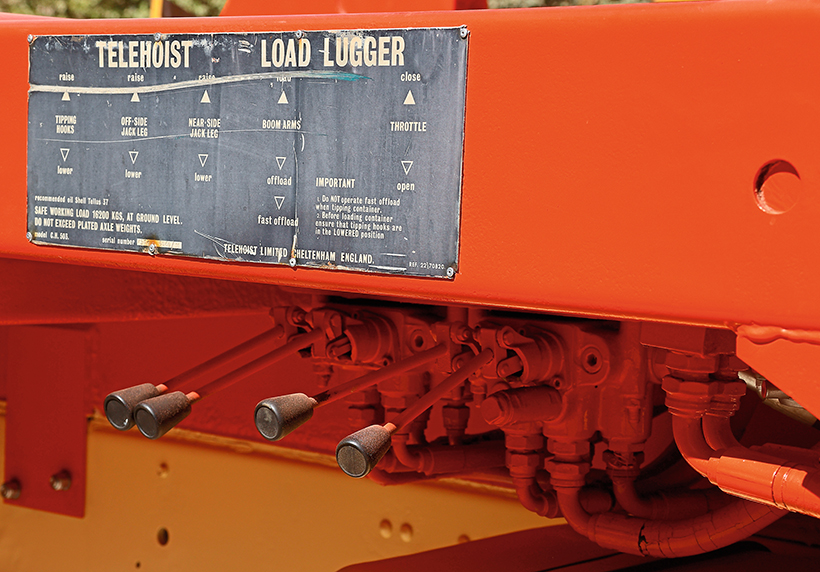

Muscular Telehoist’s operating levers.

A whole new truck was quite-rightly given a whole new engine too. The Bedford 70 Series, a six-cylinder in-line diesel with seven-bearing crank, displacing 7.63 litres and developing 136bhp at 2,800rpm, with a maximum torque of 320 lb.ft. at 1,600 rpm. The emphasis was on torque and fuel economy with the standard tank holding 26 gallons, with an optional 45-gallon unit for long-distance work.

A 15in single-plate Borg & Beck clutch was standard with two five-speed Turner transmissions being offered. Both had synchromesh on the upper four gears with one having a direct-drive fifth and the optional unit providing a 0.836:1 overdrive ratio. Strangely, rather than having a sixth ratio as overdrive, or creating slightly increased steps between the intermediate ratios to spread the cascade, the overdrive version had a much higher first gear, to maintain the same rpm decay throughout the gearshifts. In effect it was designed from top gear, downwards. This prompted many operators to additionally specify the optional two-speed rear axle. In standard form the KM was available with two final drive ratios of either 6.17:1 or 6.8:1.

Bedford’s (poor) substitute to designing a tilt-cab for its all-new truck.

The optional two-speed rear axle was also produced in two versions with 6.5:1 / 8.87:1 or 5.57:1 / 8.60:1 ratios. As can be seen from these numbers, the 16 percent overdrive created by the optional main gearbox would be almost equalled by the 11 percent difference in the two standard final drive ratios and in itself the combination of overdrive and 6.8:1 rear axle would give the best set of ratios for general haulage work. Likewise, the combination of overdrive and 6.5:1 / 8.87:1 back end would be more suited to tipper and tractor unit applications with the combination of overdrive ‘box and 5.57:1 / 8.60:1 rear axle being aimed at the long-distance haulier, giving a choice of ratios very similar to a more recent 12-speed range-change transmission. If Bedford’s goal with the KM was to hit the heavy market square-on, it certainly achieved that in gearing choices.

Lovely details abound on this perfect restoration.

No doubt from Bedford’s military vehicle experience, the KM’s suspension had a mixed on/off highway specification with eight-leaf springs on the front axle and seven (slipper-end) main leaves with seven floating helper leaves at the rear, and rubber bushed eyes all round. The brakes were particularly noteworthy. A dual-air system, with twin reservoirs making the secondary braking system a complete duplication of the service brakes which was claimed as an industry-first by Bedford at launch. The front brakes were much larger than was normal at 7in wide by 15.5in diameter, compared with 8in by 15.5in at the rear, giving over 900in of friction material in total.

Six-ton front axle features big brakes and generous tyres.

The brakes themselves were Girling wedge operated twin-leading-shoe units whilst the wheel actuators were the highly-respected Clayton Dewandre piston/diaphragm units with the diaphragms used for the service brakes and the pistons for the secondary system. Air assistance was given to the application of the handbrake too being provided by a linkage from the actuator pistons at the rear axle. Power steering, by Burman was offered as standard, where other manufacturers were leaving it as a cost-option and finally 7.50 x 20in wheels were standard, with 10.00 x 20 radials.

You only put your foot under the stabiliser once!

The modified TK cab provided plenty of space for its day, whilst the KM boasted a Bostrom hydraulically-sprung driver’s seat, a second mirror on the offside -giving a wider angle of view – and windscreen washers are standard. The larger tyres compared to a TK meant that the cab step had increased to 2ft.4in off the road, with the floor of the cab itself being 3ft.6in above ground – about two feet less than that of a top-flight 44-tonner today! With hindsight, Bedford missed a trick with KM in not offering a tilt cab, relying instead on the two rear-side hinged panels, a-la TK with added drop-down wheel arches, for better access. However, Bedford main agents still had to try and recruit fitters with one arm five feet long and nine fingers on the other! On the upside, grease points only required attention once every 24,000 miles, and the KM featured just five lubrication points for the whole chassis.

KM’s frontal mask has a purposeful look.

This chassis is a 148in wheelbase skip carrier, essentially the same specification as the midrange KM tipper. It’s owned by Paul Riches, Managing Director of Paul Riches Skips and was built in 1976. However, by the time it got into Paul’s ownership the vehicle was in need of some extensive renovation work. Originally built from new as a skip truck it had been run from new by AC Smith & Son and still sported what was left of its red livery when Paul bought it. This was Paul’s first truck and once he had it in decent condition it worked on a daily basis until 1987, when it was put into full restoration as a show truck, and the hard work taken by Paul Riches Skips’ expanding fleet. This now numbers 14 in all, mainly DAFs and Volvos, but a newly repainted Cummins-engined Foden Alpha from 2006, still sees daily duty.

A Bedford in Bedford, how fitting!

The KM looks resplendent, restored to its original Paul Riches Skips livery, a slightly modified version of which is used on the modern fleet of four and eight-wheelers.

The Bedford’s double front bumpers and quad headlamps give it a much more heavy-duty, almost aggressive frontal mask, a contrast to the rather mild looking TK. Hard to believe the cabs are otherwise virtually identical. The business-end, boasts a Telehoist Load Lugger, skip loader rated at some 16 tons the vehicle’s GVW!, so they obviously expected a bit of overloading to be handled in Cheltenham, back in the ‘70s. Before the days of on-board weighing, skip lorries were more prone to overloading than tippers. At least the JCB driver could estimate the tonnage from umpteen buckets of soil, but with a skip, who knows what’s lurking beneath the top layer. The lifting arms look long compared to the extending lifting frames on the more modern occupants of Riches’ yard – in Bedford, rather fittingly – but there’s a simplicity to the KM, making one ponder the need for more hydraulic rams, more controls, more complications – to hoist a skip on board. The cab is wonderfully original too, it’s all been re-trimmed but it is period-correct and looks factory fresh.

On the road, the Bedford keeps pace with modern traffic.

Out on the road it sounds just right too. Unladen, it bounds along quite happily with modern traffic and draws attention from truck drivers in the latest Scandinavian 44-tonnes spaceships. Before ‘Hi-Vis’ entered everyday vocabulary, a bright orange truck was just what you needed, trundling around grey and drizzly landfill sites populated by massive D9 ‘dozers and articulating dumpers. Thankfully the KM is spared such indignities these days and spends its time on the show circuit with the success you might expect of such a fine restoration. It’s no local carnival queen however and Paul recently did a Yorkshire road run with his beloved KM, from its Bedfordshire base, through Lincolnshire and a loop around North Yorkshire, a round trip of over 300miles. Not many current skip lorries see that sort of mileage from the yard. After the KM, Bedford was on a roll, moving into the 1980s with the TM, a different kettle of fish completely, but despite its much more class-competitive cab, modern looks and use of the quirky Detroit two-stroke diesel, it never quite managed to do what the KM had done. Change Bedford’s fortunes at the time, and its reputation forever.

The author wishes to thank owner Paul Riches, Transport Manager Simon Arnold, all at Paul Riches Skips and Commercial Motor magazine for access to its archive from the vehicle’s 1966 launch.

This feature comes from the latest issue of Heritage Commercials, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

Biddenden Tractorfest to celebrate FFA’s 20th anniversary

Next Post

Steamers at the Hertfordshire Steam & Country Show