Fabulous Ford 5030 tractor restoration

Posted by Chris Graham on 29th November 2020

Chris Petherick put his lockdown time to productive use by finishing the restoration of his fabulous Ford 5030, as Chris Graham discovers.

Fabulous Ford 5030: If it hadn’t been for lockdown, Chris Petherick is sure that his now fine tractor would be nothing more than a big pile of bits.

With some enforced downtime on his hands following the government’s Covid-19-driven decision to lock-down the nation, Ford enthusiast Chris Petherick took the opportunity presented by his deserted workshop and devoted some quality time to his neglected, part-restored, 1992 Ford 5030. The result, as you can see here, is something very special, indeed.

“I grew up in North Molton, Devon, and Ford tractors have been in my blood for as long as I can remember,” Chris explained. “I used to help out on local farms to earn some extra pocket money and, on one of them, they’d just bought a brand new Ford 5030. It was a low-profile model fitted with a front loader and, best of all, I was allowed to drive it. This was fantastically exciting as I was only about 12 at the time, and the thrill of driving around in that ‘enormous’, shiny machine, made a massive impression on me.

Motor trade beckons

However, when Chris left school, it wasn’t farming he went into, but the motor trade. “I started with a college apprenticeship in vehicle mechanics, then got a job at an independent garage where I was trained in vehicle bodywork repair techniques and spraying. After this I moved to BMW, where I took all the training opportunities I could, and reached Master Technician level.

“While I was doing this, though, I kept one eye on the agricultural market, and had noticed that there wasn’t anyone locally offering a top-quality repair service for damaged tractors. So, I started doing some weekend repair and respray work for the local agricultural equipment dealers, and the demand for my services just grew and grew.

Having vowed never to take on another tractor while up to his elbows in the 5030 restoration, Chris Petherick is now thinking about perhaps tackling a Ford 4000 or 7000 as his next project.

“It wasn’t long before I was able to leave BMW, become self-employed and set up as an independent car technician and repair specialist. To be honest, though, most of my time was spent repairing and painting damaged tractor bodywork and wheels. I’d also become proficient with plastic welding and fiberglass repair, so could to offer a pretty comprehensive service.”

Things went well with the business and, after a few years, I found myself with enough spare cash to afford my own tractor and, of course, my heart was set on a Ford 5030. But finding the right example was easier said than done. My search started in 2014, and I wanted one with a Deluxe cab, long wings and low hours.

Lengthy search

“But it took me years – literally – to find the right machine; I’d looked at so many that just weren’t right, and was starting to get fed up when, in 2018, an alert popped upon my phone with what looked like something promising. It certainly had low hours – just 2,500 – and the right cab, but it appeared scruffy, and was located in North Wales. It was a running, 1992 model priced at £11,500, which was more than I wanted to spend.

Removing the heavy cab involved inching it clear with a block and tackle winching arrangement. Fortunately, there’s no shortage of headroom in Chris’ workshop.

“Apparently, it had done only light, clean work on a campsite from new, moving caravans around – hence the low hours. I was interested and, as luck would have it, a tractor dealer friend of mine was attending a sale in North Wales, and he agreed to have a look at it for me.

“His verdict was that it was in OK condition, although he reported bulging tyres, corrosion in the cab, problems with the roof, broken cab glass and a missing door. On the plus side, though, he’d managed to negotiate the price down to £10,000. I was happy to pay that and the deal was done.

“Once the 5030 was back in Devon I was really excited to see it, and got a lift to my friend’s yard so that I could drive it home. It was pouring with rain and, to be honest, my heart sank when I saw what I’d bought; it looked like an absolute dog! The remaining door was cable-tied closed, the roof looked like it was being held together with tape, the roof lining was drooping badly and the cab steps were rotten. It didn’t make a great first impression!”

Mechanically sound

“But the engine started well enough although, the first time I moved it, I got drenched by a shower of water that had been held on the roof somewhere… what had I done? However, the six-mile drive home was uneventful and, once back, I got the 5030 straight into my tractor-sized spray booth so that I could have a proper look at it.

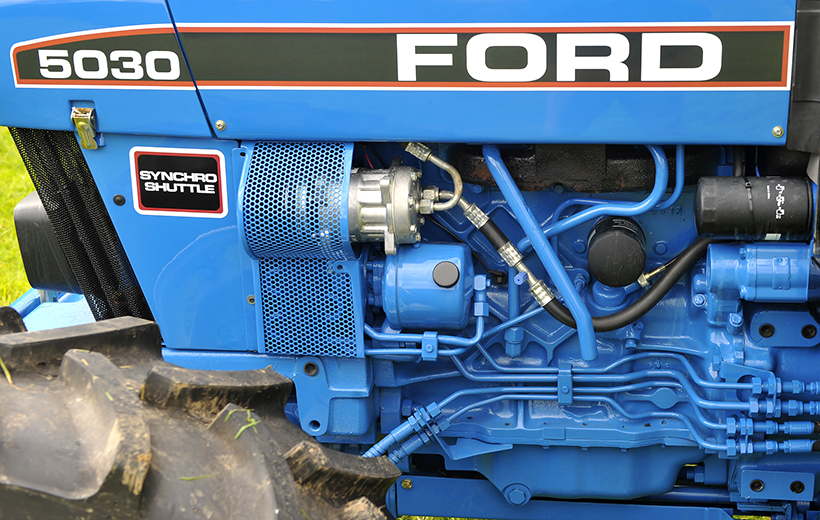

There was a good deal of careful re-engineering required with this project, to enable the installation of both a turbocharger for the engine, and air conditioning for the cab.

“It had proved itself to be mechanically sound on the drive back, but I still checked the engine carefully for signs of oil leaks, but found none, which was good news. Then, stepping back and taking a few moments to think about it properly, I realised that, although the bodywork and cab looked pretty bad, it was nothing that I couldn’t deal with, and my mood began to lighten. Also, I discovered that this model was fitted with the optional, dual fuel tanks, which cheered me up even more.

“My Dad, who was an agricultural mechanic specialising in Ford tractors, has always been a great fan of turbo-charging, and his enthusiasm certainly rubbed-off on me; I love them. So, one of my first plans with the 5030 had been to fit a turbo, and that’s what I did. On Dad’s recommendation, I bought a Ford 7610 turbo installation kit from MJ Robinson Tractors, in Burnley, and set about fitting it. A slight modification to the fuel tank was required, creating extra space for the intake pipe, but everything else was fine.”

The work begins

“Then, a week or two later, Dad and I decided simply to spend a weekend tearing the whole tractor apart. The cab was removed, which was a bit job in itself, so that everything could be thoroughly steam-cleaned. We set-up a block and tackle to lift the cab off, and I was careful to bag and label all the fixings as I wasn’t sure how quickly it would be put back together again.

Chris is indebted to the help and advice he got from his dad, and says that he couldn’t have done without his technical tractor knowledge.

“But stripping the cab just revealed more and more rust, which is when I realised the full extent of the repair work needed. It was clear that it would take some time to sort out properly and, as my regular work was starting to pile-up, the 5030 was put into a spare garage, and the cab was moved out into the yard, and stored under a cover. Things then stayed like that for the best part of a year.

“Then, early in 2019, when work was quiet, I decided to get cracking on the cab again. I bought an 8×4 piece of sheet steel and my work colleague – Phil – and I just got stuck in. I think it took about two months to fabricate all the repair sections that were needed for the cab, and Phil spent a lot of time straightening the tractor’s other, damaged body panels. There just wasn’t a straight one left on the tractor, when I got it!

“Generally, I think the cab on the 5030 lasts pretty well but, in this case, the problems had been caused a broken window glass letting water in. It had just rotted from the inside out. The roof was in a hell of a mess, too. Corrosion had spread to about 60% of it, so that took a lot of work to put right. It’s a surprisingly technical structure, incorporating the sunroof, lifting side panels that provide access to the air filters and lots of hinges.”

The low recorded hours, relatively light-weight duties since new and decent maintenance ensure that the engine didn’t require a rebuild as part of the restoration.

Cab problems

“One corner of the roof was completely rotted, and this had eaten down into the top corner of the cab frame, too. I spoke to Sekura, in Denmark, who made the cab, only to discover that the company been instructed by Ford to destroy all the panel presses and tooling relating to the cab, and that this had happened just six months before I got in touch! All that was available was some door rubber seal.

“In fact, I spent ages searching for spare parts for the cab, and the rest of the tractor, come to that. It really was a time-consuming job and, altogether, took about six months. It amazed me just how difficult it was to source bits for what, after all, is still a relatively new machine. And I’m not talking about obscure parts, either; components like new mirror brackets, door handles and latches are just unobtainable nowadays.

Then, through a friend of a friend, I heard about somebody who’d bought a whole Ford tractor spares department from a business that was closing-down. I went to have a look and found loads of stuff for the 5030, so made him and offer and bought the lot! There were lots of parts that I didn’t need, but I’ve since sold those on eBay which, as it’s turned out, allowed me to make a decent profit, overall.”

The seat looks standard but, beneath the surface there lurks an air-suspension system which delivers much greater comfort for the driver. Enhanced sound-deadening makes it quieter inside, as well.

Strange times

“By the time I’d gathered the parts I needed, we’d arrived in March 2020 and the country was about to head into the Covid-19-related lockdown. Work bookings dried-up and, all of a sudden, I had a lot of time on my hands which gave me the perfect opportunity to crack-on with the tractor. I managed to borrow a mobile sand-blasting set and treated as many components as I could, including the wheels.

“The lovely weather meant I was able to put-in uninterrupted, 15-hour days, and really made some great progress. Everything went to plan with the re-assembly. The front axle had been removed and stripped completely, and I sent all the pins and wheel nuts away to a specialist who ‘yellow-plated’ them for me, re-creating that authentic, factory-fresh look I was after.

“The engine, gearbox and back end were then primed and painted. I’d also removed the turbo and sent it away to Turbo Dynamics, in Christchurch, Dorset, to have it upgraded to Stage 1, for a bit more boost. The fuel pump was reconditioned and tweaked, too, so that it matched the 7610 spec.

The cab took a lot of restoration; water leaks had caused it to rot from the inside out, and the roof panel was in a bad way, too.

“I used stainless steel screws and fixings at every opportunity to guard against future corrosion, and managed to re-fit the cab on my own, having found a replacement door frame which I had to straighten and fit with rebuilt hinges. All this happened quite quickly, but the process slowed down again once I started fitting-out the cab. Sourcing the correct window seals, interior trim pieces and sound-deadening foam was a struggle.

“I borrowed a 5030 from a customer to help remind me about how everything inside the cab went back together; I was determined to get it all right, including the orientation of all the fixings. I also spent a long time re-painting the gear and selector levers, and connecting the linkages. Finishing that stage took me until about July, by which time the tractor was just about drivable.”

Detailed touches

“The heater fan and many of the switches had to be replaced – most of the connections were badly corroded due to the water leaks. Locating the correct switches (displaying the right graphics) was another, time-consuming challenge.

This 1992 5030, in its newly-restored form, now benefits from a turbo-charger that doubles power output, air conditioning and an air-sprung seat.

“One of the few departures from the original spec inside the cab, relates to the seat springing – I opted for an air-sprung unit to replace the standard set-up. You wouldn’t know to look at it as the mechanism is concealed, but the end result is certainly much more comfortable. I also had to fabricate a new seat pan, as the original was too badly corroded to use.

“Once everything was back together, I serviced the tractor and changed the oils. Then, with it running and drivable again, I decided – purely as a technical exercise – to fit an air conditioning system. This meant that the roof had to be removed again, and I had to re-design the heater box to allow the evaporator to be fitted.

“Most of the installation is hidden; the pipes are routed down inside the cab’s frame. However, I had to re-locate the alternator from the side of the engine to the top, to accommodate the air compressor. I also had to remove all the tinwork (without scratching it!) because the layout of the cooling set-up (oil cooler, transmission cooler and radiator) needed to be re-worked to create space for the condenser (from a Ford 7840).

In its past life, this tractor occupied its 2,500 recorded hours shunting caravans around on a campsite in North Wales.

“I bolstered the system by fitting a County water pump (with a double pulley), so that the compressor would work from the alternator’s original position. This was an involved process and, part way through, I did find myself wondering what on earth I was doing. Thankfully, it all turned out OK in the end. However, I’m indebted to the help and advice I got from my dad; I couldn’t have done without his technical tractor knowledge.

“When I took the finished tractor for a dyno test, it registered 91hp at the PTO, which is just about double the standard power output. I’d never seen a tractor on a dyno before, and found it a scary process. Seeing – and hearing – the engine being revved so hard was pure torture for me!”

So, it’s been quite a rapid end to quite a lengthy restoration project, but there’s no doubting the quality of the finish Chris has achieved with his 5030. The tractor is a joy to behold and, hopefully, the photographs here do it justice.

Chris intentionally moved his 5030 away from standard specification, but has no regrets about doing so. His aim was to create the tractor he wanted, and it’s clear from chatting with him that he’s done just that. He’s evidently delighted with the way the 5030 now looks and drives, and his happy to have created what he describes as “a proper little pocket rocket that makes a fantastic noise!”

For a money-saving subscription to Ford & Fordson Tractors magazine, simply click here