Restoring a Ford Silver Jubilee 7810 tractor

Posted by Chris Graham on 15th March 2024

James Connolly talks to Colin Elliott about what was involved in restoring this Ford Silver Jubilee 7810 to such a high standard.

Ryan Graham, from Co. Tyrone, recently commissioned Colin Elliott to restore his Ford Silver Jubilee 7810.

This 1989 Ford Silver Jubilee 7810 is owned by Ryan Graham, from Fivemiletown in Co. Tyrone, and has recently been restored by Colin Elliott, from Markethill in Co. Armagh.

Colin’s work as a tractor restorer will be familiar to regular readers of Tractor & Machinery, as he has featured in a previous issue with the restoration of a John Deere 3650.

It took three months and more than 520 hours to restore this tractor to its current condition.

This article provides detail on the restoration and history of Ryan’s tractor and, where possible, some detail of the story of the Silver Jubilee 7810, from 1989 to the present day.

In 2020, Ryan purchased the Silver Jubilee 7810 in off-farm condition, from John Kennedy of Grove Farm, Annacloy, Co. Down. It is interesting to note that this Silver Jubilee 7810 has no air conditioning or Performance Monitor fitted.

At first glance, the tractor appeared to be in good order. (Pic: Colin Elliott)

Ryan’s intention was to fully restore the tractor when time and money were available to do so. Unfortunately, the Covid-19 pandemic hit, which put his plans on hold for a couple of years, but during this time Ryan was able to assess the Silver Jubilee and decide what was needed to achieve the standard of restoration he had in mind for the tractor.

At that stage, the 7810 had two double-acting spool valves and just one rear assistor ram. Ryan decided to upgrade the spec on his tractor and fitted a second assistor ram and two additional double-acting spool values, in keeping with what was available for the Silver Jubilee models in 1989.

From a mechanical point of view, the 7810 was in good working order because the previous owner had recently overhauled the engine. As part of the repairs, the fuel pump and injectors had been reconditioned, a new core had been fitted to the radiator, and the clutch had also been replaced.

The main items that would require attention, like many of the 7810s of this age, were the Super-Q cab and the paintwork. In late May 2023, the tractor was delivered to Colin Elliott’s premises and the three-month restoration began.

Firstly, Colin drove the tractor and after getting the 7810 well warmed up he checked that the brakes, Dual Power, and digital dash panel were all functioning as they should. Anything not working properly was noted and added to a list for repairs.

The cab on this particular 7810, like many other Super-Q cabs, was in a poor state, with rust in all the usual problem areas. (Pic: Colin Elliott)

The tractor was then left to sit overnight to check for any leaks the next morning.

Colin detected only a small diesel leak at the lift pump, which was replaced before the main restoration work began. He then replaced the track rod ends and set the front tracking, as the tractor had just been fitted with new Goodyear tyres all round – with 420/70 R24 at the front and 480/70 R38 on the rear.

To give himself good access to the engine, Colin removed the exhaust and all the tractor’s panelwork, including the bonnet, side panels, front grille, and cowling. He then removed the radiator, the four-wheel drive guard and propshaft, plus any component that could harbour dirt. The tractor was then given its first wash and left to dry before being pushed into the workshop.

The Super-Q cab was then removed from the tractor and bolted to a portable cab stand that Colin had built to make life easier when working on this large unit. After the cab was removed, both plastic fuel tanks were taken off the tractor, along with the engine and chassis wiring harness.

All remaining auxiliary components, such as the three-point linkage, pick-up hitch, cab control linkage, and spool valve blocks, were removed along with the battery tray and cab steps. Once pushed outside again, the tractor received a second wash to make sure it was as clean as possible.

Repairs were also needed to the panels below both rear side windows on the cab. Both metal mudguards were also replaced with good secondhand originals.

Methodical process

When dry, the tractor skid unit was pushed back inside and placed on axle stands and all four wheels were removed. Colin does not shot blast the engine, gearbox, or rear end of any tractor he restores. Instead, he cleans and prepares all these areas by hand with a combination of sandpaper and a mixture of wire wheels powered by a hand-held grinder or a cordless drill.

He also uses a parts washer brush, along with petrol or paraffin to clean out those areas around a tractor that are particularly hard to access, such as the front hubs and the Hardy Spicer couplings.

Colin does use the shot blasting process during his restoration projects, but only where it is appropriate to do so. Any solid steel or cast-iron items belonging to the tractor, such as front weights, wheel rims, lower links, panel work, and pick-up hitch will be cleaned this way. Shot-blasting will find and highlight any weak, or badly corroded areas, and anywhere that filler has been used to cover up hidden repairs of any kind.

Once all areas have been thoroughly cleaned and prepared on the skid unit, Colin uses etch primer on any bare steel, followed by four or five coats of filler primer to round off the texture of the cast iron, so that a good finish can be achieved.

He applied three coats of 2K (two pack) Ford Blue to the skid unit. The first of these coats is applied lightly to ensure that the paint gets into all the corners and hard-to-reach places. Then, two final coats are applied to get a gloss shine.

The cab almost ready to be reunited with the skid unit. (Pic: Colin Elliott)

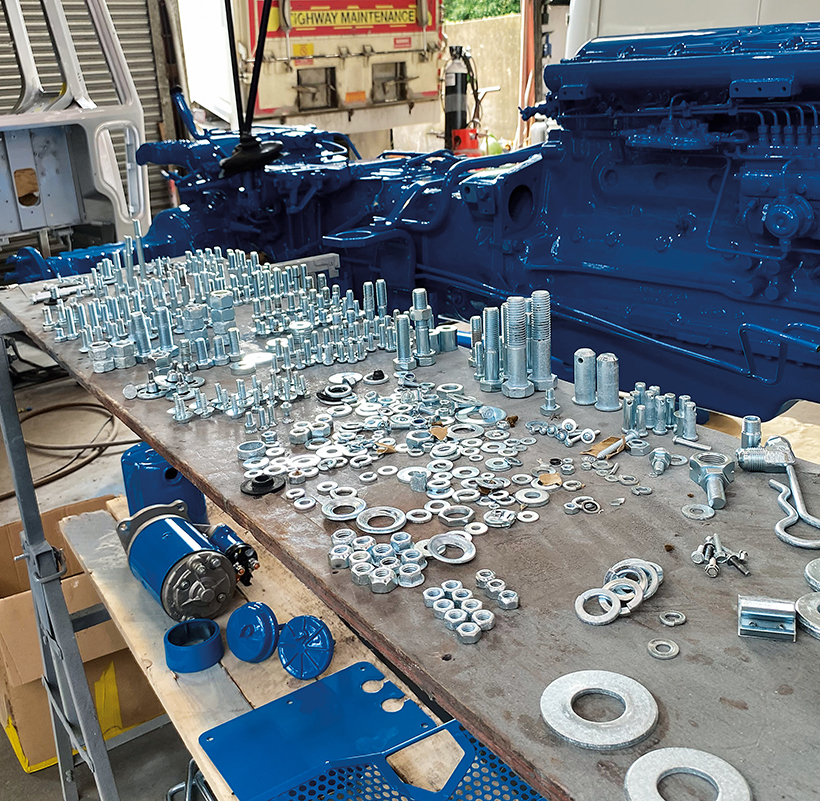

Colin stated that at least three large buckets of parts, such as nuts, bolts, washers, various brackets, and linkage rods, were all hand cleaned and prepared using a wire wheel on a cordless drill. These items were then sent to be zinc-plated before refitting to the 7810. These small touches really set the tractor off.

Next on the list was the cab itself, which was taken down to its bare shell by totally stripping off all major components, such as the roof, glazing, doors, dash unit, seat, orbital unit, fixtures and fittings, interior cladding, and sound-proofing materials. The wiring loom and multi-plug connectors were labelled and photographed for future reference.

The same was done to the engine and chassis wiring loom for the tractor. Colin also checks and repairs any items requiring attention on these wiring looms and will re-cover any areas needed to make the wiring look like new before refitting to the tractor.

Colin stated that he is confident that the tractor is a genuine Silver Jubilee 7810 because the tractor was painted correctly in all the right places – even in areas that were hidden from view, such as behind the dash, below the cab cladding and sound-proofing material.

Problem areas

When stripped out and sandblasted, the Super-Q cab had rust holes and corrosion in the usual places, such as the panel at the bottom of the front screen. The floor area at the door on both sides of the cab was also badly rusted and needed replacing. The sill panels on both front lower windows, and the lower area around the bottom half of both side window frames also needed repairs.

Hundreds of fixings and linkages were zinc-plated to complete the look. (Pic: Colin Elliott)

Cab Tractor Specialists in Ballymena can offer replacement repair panels for these areas, which are notorious rust areas for the Ford Super-Q cab. Colin was able to cut out the bad areas of rust and renew them with these replacement repair panels.

Unfortunately, other areas needing panel work replaced on the cab had to be shaped and fabricated by hand to carry out the necessary repairs. This was something that Colin had to do to both doors of the cab around the lower area of the large top window frame and the panel below the bottom of the lower window frame. All this fabrication work takes time, and it is easy to see how the hours can stack up on such a project.

After all the cab fabrication and repairs had been completed, it was time to prepare the cab for painting, along with the other areas of the tractor that had to be painted silver. This included the bonnet, front cowling, front side panels, and wheel rims.

These large areas of silver paint are the stand-out components of the 7810 and catch your attention when looking at the tractor – requiring the most work to get right. Firstly, all items received a good coat of grey primer, which was followed by three coats of silver base paint. Then, two to three coats of clear lacquer, to achieve that all-important finish, were applied.

Another two paint colours that are used on these tractors are satin black and Ford Tractor Grey. Satin black is used for the front grille and cab steps, and Ford Tractor Grey (white) is used for the cab roof and hatch.

The amount of work involved in projects like this one should never be underestimated! (Pic: Colin Elliott)

After all the paint work had been completed, the rebuild of the cab interior could begin. Firstly, the cab wiring was installed, along with the sound-proofing material and cab cladding around the inner mudguards and the hydraulic quadrant. Every item was reinstalled in the reverse order it was taken out.

Colin was very complimentary about the cab interior supplied by Tractor Cab Specialists of Ballymena. He said that it fitted very well, and that it was a very good reproduction of the original cladding. He was able to re-use some of the original cladding around the roof hatch by using new foam backing. The company also supplied most of the decals, and recovered the Bostrom seat after Colin resprayed the seat frame.

All the glazing was refitted to the cab along with a new front screen, as the old one was badly scored by a worn wiper blade. The floor mat for the cab was in good condition and was able to be used again after being thoroughly cleaned.

Then the tractor skid unit received new hydraulic and power steering pipe work all round. All the filters were replaced, including the rear hydraulic filters, and the engine and hydraulic oils were replaced. The wiring harness for the engine and chassis was also re-installed.

Looking the part

Both fuel tanks for the tractor were refitted, after being thoroughly cleaned, and a new starter motor and alternator, along with a fresh set of battery leads and a new battery, completed the electrical overhaul. The tractor really started to look the part when the four silver GKN Sankey wheel rims had the new Goodyear tyres refitted.

Russ Davidson’s tractor is the one that featured at the 1989 Royal Highland Show, and features an openable lower window panel. (Pic: Russ Davidson)

Although the 7810 has been out of production for quite some time now, some parts are still available from New Holland. Local New Holland dealer, Burkes of Cornascriebe Ltd., was able to supply items such as four new work lights for the roof of the Super-Q, new stop/taillights at the rear of the tractor, indicator, and side lights for the top of the mudguards.

It also supplied new throttle and handbrake cables, outer door handles, chrome levers for the bonnet catches, and a Ford badge for the front cowling.

Through the New Holland parts network, Burkes was able to supply genuine Generation III decals for the front side panels, which came from dealers in England and France. New gas struts for the doors and roof hatch also came from Burkes, along with exhaust manifold gaskets and a genuine rocker cover gasket for the engine. Burkes also supplied all the service items for the tractor, including the oils.

Local firm Simms Bros., of Loughgilly, also supplied parts for the tractor and was able to provide a replacement exhaust for the 7810. Unfortunately, due to its age and condition, the original Burgess silencer was unable to be used again. The company also supplied new front mudguards for the tractor.

The next stage of the restoration was to refit the Super-Q cab to the skid unit and reconnect everything. This took time and a lot of patience.

A certificate of authenticity and pewter model were gifted with every Silver Jubilee 7810. (Pic: Matthew Henderson)

One of the last jobs to complete the tractor was to fit the decals.

Today, the Silver Jubilee 7810 tractor is a very sought after and much-admired model with collectors of classic tractors, especially Ford enthusiasts. It is at this point that I aim to explain the complex and often confusing history of the model and point out the many questions about these tractors that remain unanswered.

On 1 June 1989, all Ford tractor dealers in the UK received a letter from the Marketing Manager at Ford. It informed them that it had been decided to make a special edition model to mark the important anniversary of 25 years of tractor production at the Ford factory at Basildon, Essex.

The four-wheel drive 7810 was the tractor chosen to be that model, as it was the best-selling tractor in the Ford range at the time. This would take place over the last seven months of 1989.

The tractors would be available to the dealers in three phases. Phase one would begin in July and be completed by the end of August 1989. The interesting thing to note is that all the units in this period would be built with air conditioning.

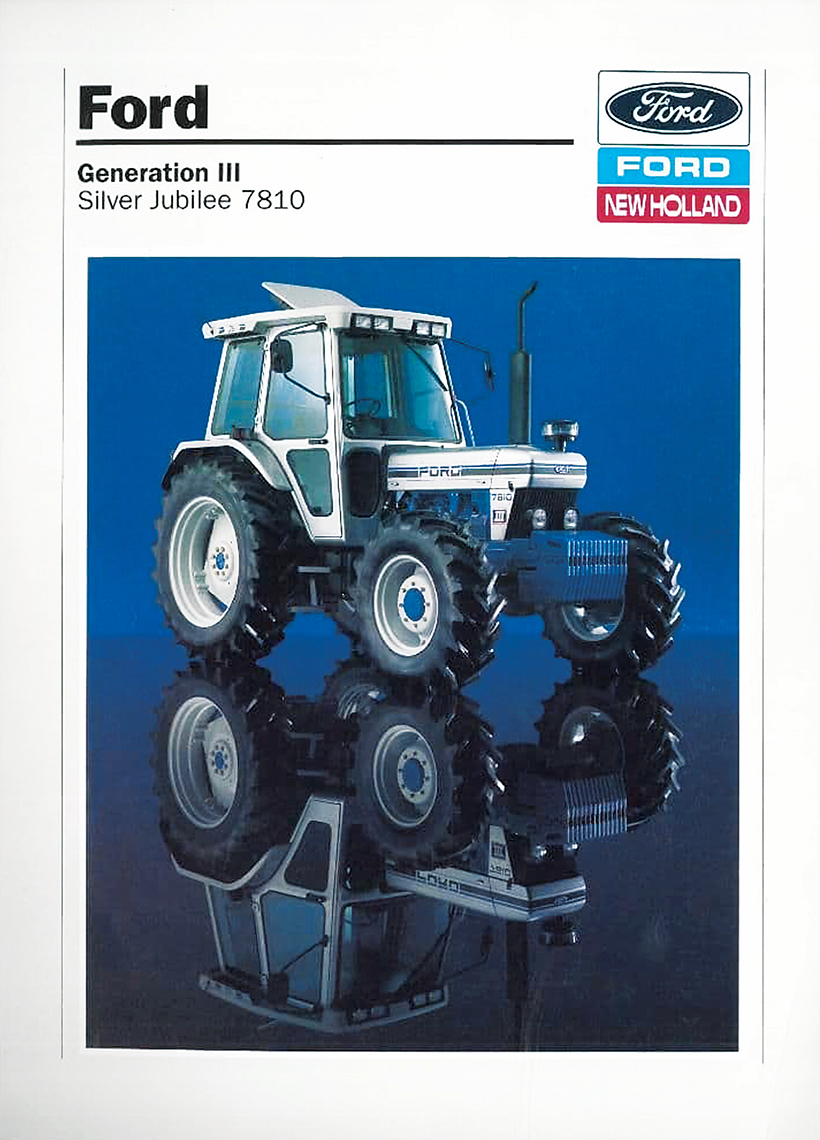

The brochure for the tractor. (Pic: Agrimanuals)

The second phase would be supplied to the dealers by the end of October 1989, with half available with air conditioning and half without that option.

Then, the final phase would begin in November 1989 and be completed by the end of the year, with the same 50:50 arrangement regarding air conditioning.

UK launch

The building of these special edition models would be fitted around the production of the standard Ford tractor models produced at Basildon if everything went according to plan.

The launch of the Silver Jubilee 7810 took place in the UK at the Royal Highland Show in June 1989. The tractor on display at the show now belongs to Jim Davidson, from Scotland, and was built at Basildon on 11 May 1989 during the day shift and is a full-specification model.

Interestingly, the cab on this tractor has an openable lower rear window panel and is believed to be the first Silver Jubilee 7810 produced – but this is a matter of debate among Silver Jubilee enthusiasts.

The tractor features four double-acting spools and two assistor rams.

The question that is often asked about the Silver Jubilee tractors is: “Did Ford produce any in Force II form, with or without the digital dash?” I have been told that examples of Silver Jubilee 7810 Force II tractors exist, but to answer this question I think it comes down to the build dates, which would have to be within a very specific timeframe.

My understanding is that Ford tractors changed from Force II to Generation III on 1 April 1989, and it could be possible that these enthusiasts are talking about a few pre-production tractors built at the factory as test mules before proper production began, or tractors badged as Force II models without the digital dashboard for certain world export markets.

The problem in answering this question is that without clarifying with the owners of these tractors the facts regarding the build date, the build specification, where they came from, their history and documentation, it is extremely difficult to give a definitive answer.

There are two very interesting points regarding this debate on production models of the Silver Jubilee 7810. The first is the picture of the launch tractor taken at the Ford stand at the 1989 Royal Highland Show. It shows the Silver Jubilee tractor with Generation III decals and no front mudguards, as does the rare, original brochure for the tractor.

The second point is that on the back of the brochure it states that the Silver Jubilee 7810 is “based on the best-selling Ford 7810 Super Q incorporating all the refinements of the Ford Generation III.”

Shod with new Goodyear Optitrac tyres, the tractor looks amazing and is testament to the hard work put in by Colin.

Those that bought a new Silver Jubilee 7810 received a pewter model on a wooden plinth. The registration number on the model matched that on the actual tractor, and Ford also provided a certificate of authenticity with the purchase of these special edition tractors.

This was certainly the case in the UK, but there is uncertainty whether the same applied for tractors destined for export. Perhaps someone reading this article from outside the UK could provide an answer to this question.

These special edition tractors had a silver bonnet, silver cab (including the rear mudguards), silver wheel rims, and different bonnet decals, complete with a black front grille and cab steps. The number ‘25’ was also applied in decal form to both sides of the cab roof at the rear, just above both side windows.

A full-specification Silver Jubilee 7810 could have air conditioning, Performance Monitor, four double-acting spool valves, two assistor rams, and a full set of front weights. Not all Silver Jubilee 7810 tractors were the same, however, and in part two of this feature I will explain the subtle differences, as well as share the story of this particular tractor.

This feature comes from a recent issue of Tractor & Machinery, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

Superb classic bus running day in Winchester

Next Post

1918 Amanco stationary engine working again