1918 Amanco stationary engine working again

Posted by Chris Graham on 18th March 2024

Darren Curryer reports on a 1918 Amanco stationary engine that, having missed its wartime service, finally got to cut some timber!

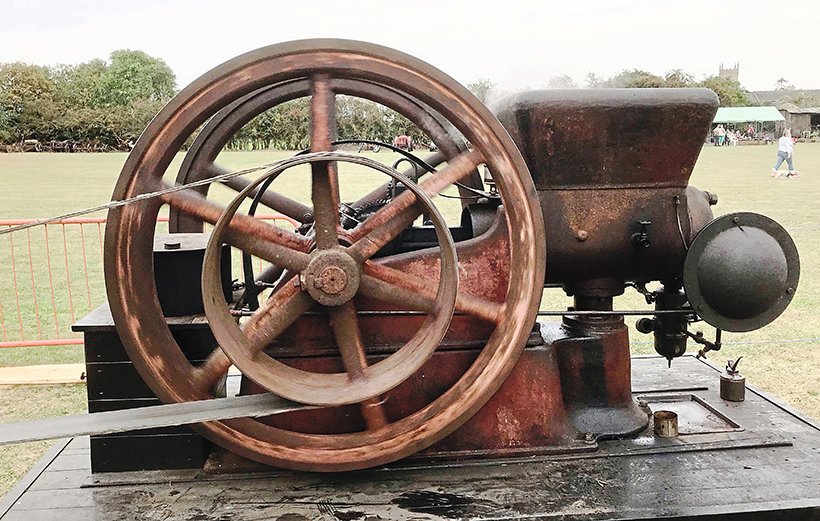

1918 Amanco: The engine, a 12 Mule Team Amanco of 1919

Early in 1918 the Canadian Forestry Corps placed an order for an Associated Manufacturers 12 Mule Team engine. It was ordered to power the saw in the sawmill it were operating near the village of Ardgay, in the Scottish Highlands.

The Canadian military was operating a lot of these mills at that time, supporting the war effort by producing trench timbers, pit props and the like. However, the time taken for communications, and the long distances involved in shipping, meant that by the time the engine arrived in Ardgay, it was early 1919 and the war had already ended!

Another view of the engine.

As the engine was immediately surplus to requirements, it was put straight into storage. How long it remained like this is unknown but, eventually, it was pressed into service driving a small barn threshing drum that was used for separating corn and wheat grain from the stalks. This continued until the engine was replaced by a tractor, shortly after the end of WW2. After this the engine returned to storage in a barn, where it remained until the 1960s. At this point it was saved for preservation, but remained largely untouched until 2016, when it was brought back into the running condition you see it in today.

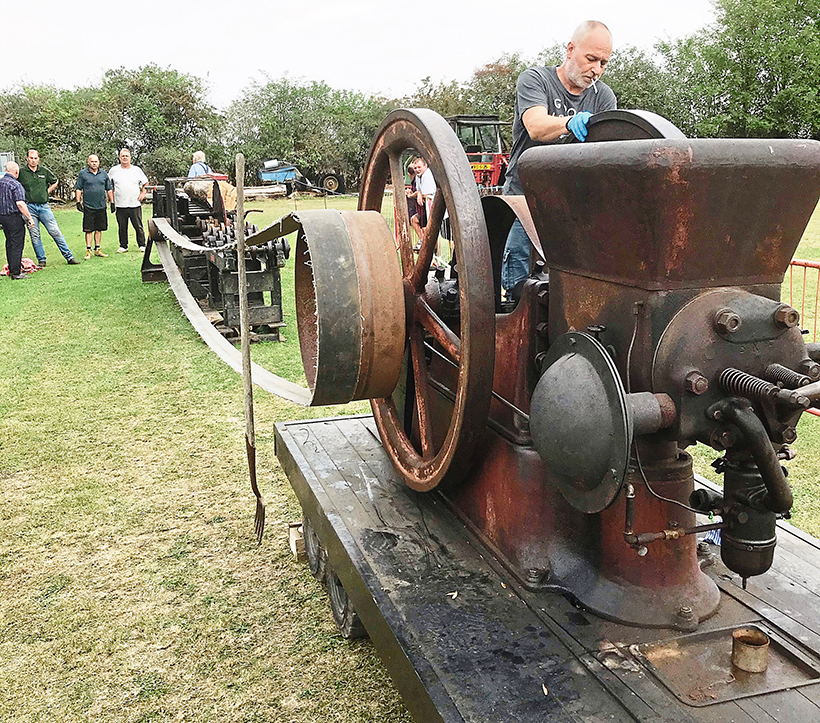

There’s nothing better than the sound of an engine working!

Fast-forward to 2023 and the opportunity arose for the engine to finally do what it was intended to do. A friend asked if I’d take it to his place so that we could belt it up to a rack saw. A date was agreed and we hauled the engine over. The rack saw was already set up in his paddock and some tree trunks had been laid nearby in readiness, along with a tractor to load them.

The engine has been made to run nice and slowly for exhibiting purposes; something it does really well. But, for some serious belt-work, it was going to need to be run considerably faster. A little while was spent making the necessary adjustments to the governor and, once I was happy with it, the belt was attached. More time was spent getting everything aligned properly, and also making sure that the tension was right – if it’s too tight it can cause the main bearing on the pulley side to overheat.

Ready to go; the engine is started with a pull on the flywheel.

When we thought all was ready, the first trunk was loaded. The claws were hammered in to secure it to the table, and the engine was started. An engine of this size needs a bit more pulling over to start it than smaller ones and, with the belt fitted, it required even more effort. Fortunately, it’s a great starter and soon fired into life. We let it run for a minute or two. Then we decided that it needed better aligning as the belt wasn’t very well-centred on the pulleys. After a little repositioning we were happy, but we’d noticed the engine bouncing on its truck, which was making it move a little, hence the misalignment. Erring on the side of caution, a tractor was coupled up to the drawbar to hold it steady.

The trunk is wound through by hand on this Stenner rack bench.

Finally it was time and, with me standing by the engine to keep an eye on it, the first cut began. Hearing the big engine thump as it came under load was really quite something. The belt was dancing and the blade of the saw was singing as it made its way through the timber. The smell of the sawdust, exhaust and an engine steaming at working temperature; it really was quite a moment to be there and experience it all happening!

Another plank on its way.

Throughout the afternoon we cut planks of wood up to 18in wide. There was no rush, we’d do two or three and then stop for a chat or a cup of tea. The saw worked well and the engine performed admirably. We didn’t go daft and load it too hard, in part due to the bounce of the truck, but also because there was no need to work a 100+-year-old engine too hard when we were only doing it for fun. It did make me wonder how hard it could be worked, though, if it was set up properly and bolted securely to a concrete base. I have no doubt it would have made a great workhorse and, if looked after, would have given very many years of solid service.

First cut done and a little time-out to stop and check everything.

I think it’s fair to say that all involved had a great few hours, and I owe them all a huge ‘Thank you’ for making it happen and helping out. It’s something I’d like to do again. Having gained a little more experience now, I think we could improve the performance; a heavier belt would have been better, and adding some extra rigidity to the truck would stop it bouncing and allow it to run a a bit faster, maybe. Hopefully we’ll give it another go sometime, and find out. Once I’m done with cutting timber, I think it might be quite good to try it on a threshing drum, too!

This feature comes from the latest issue of Stationary Engine, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

Restoring a Ford Silver Jubilee 7810 tractor

Next Post

Recollections of the superb Sussex Steam Rally