Fordson ET7 petrol tanker restored

Posted by Chris Graham on 7th November 2021

Peter Simpson takes a trip to Essex to meet Paul Le Strange and his superb, newly-restored Fordson ET7 petrol tanker.

Paul Le Strange’s superb, newly-restored Fordson ET7 petrol tanker.

One of the star turns at this year’s Classic & Vintage Commercials Show at Gaydon, was Paul Le Strange’s newly-restored Fordson ET7 petrol tanker. It certainly drew – and deserved – many complimentary comments. But what wasn’t so obvious was that this particular restoration had a slightly unusual starting-point.

First, though, a little about the owner. Essex-based Paul is, it would be fair to say, something of a ‘serial restorer’ of lorries, and his name will be familiar to some of you as we’ve featured several of his projects in the past. By day, 58-year-old Paul runs his own, long-established and highly-respected lorry servicing and repairing business. He’s been repairing lorries since he was 16, and self-employed from the age of 22 and, as we’ll see later, as a result, he knows a lot of local lorry-people.

The Perkins engine was an extra-cost factory option; unusual then, even more so in survivors!

Other lorries in his collection include a 1937 Fordson BBE that was new to Watneys as a brewer’s dray (and also on show at Gaydon), along with an ERF A Series and Foden S39 which are owned jointly. He’s also something of a Land-Rover enthusiast/collector. However, he freely admits that he derives at least as much pleasure from the restoration process as he does from ongoing ownership/preservation. Consequently, a number of his previous projects have been moved on for others to enjoy owning.

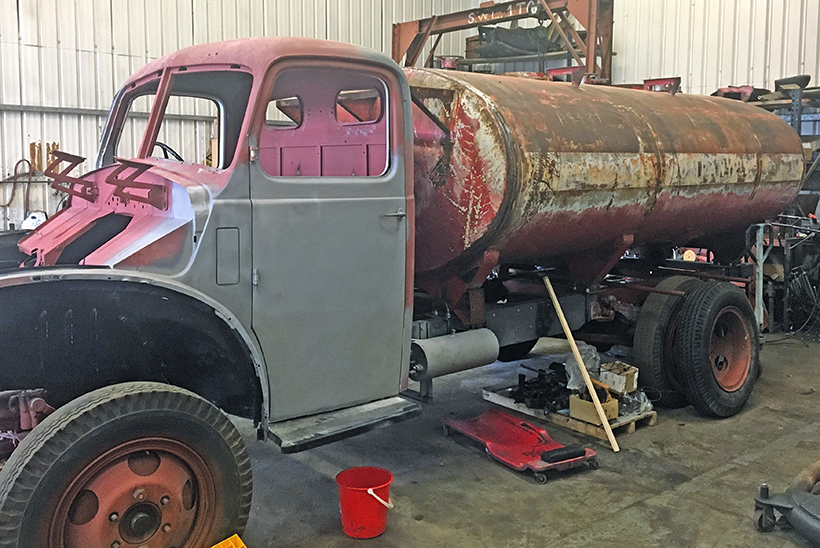

Back, though, to the subject of this particular feature. Most lorry restorers start a restoration with the lorry – ie, a complete lorry or, at the very least, enough of one to establish an identity. If a replacement body is needed, that generally comes later.

Here, though, it was actually the tanker body that came first, and by quite some margin. Paul’s business is based on a farm in South Essex, and the tank in question had been on the farm for, basically, as long as anyone could remember; it was used as on-site storage for red diesel. How it got there is now lost in the mists of time – it may have come from a Paragon Petroleum tanker as they were local and used to supply the farm, but that’s totally unconfirmed.

The cab interior is presentable, but a ‘work in progress’ that Paul plans to improve.

What is known, though, and really very remarkable indeed, is that the tank was in completely original condition, and totally as removed from the tanker chassis it had been fitted to! This included all the original dipsticks, covers, valves and the catwalks on top; even most of the original labelling and the manufacturer’s plate confirming it had been made by The Steel Barrel Company Ltd., of Uxbridge, Middlesex, in August 1961. It was in remarkably good condition too; though the original paintwork was faded and generally ‘distressed’, it was totally original, even the tanker ID was readable. The tank was also refreshingly free of dents and other damage.

In short, it was the ideal tanker body for a preserved tanker, and Paul earmarked it for use as and when a suitable chassis came up for sale. That happened just over four years ago, when a 1958 Fordson ET7 chassis-cab unit, in need of full restoration, was advertised on a ‘well-known internet auction site.’ This particular unit had, from Paul’s point of view, two major plus-points. Firstly, though being sold as a chassis-cab unit, it was a former tanker, and pretty-much all the tanker-specific kit – apart from the tank itself, but including the power take-off, cargo pump and so on – were present. Secondly, it had the Perkins P6 diesel engine; this was an extra-cost option when new; rare then and even more so today.

Paul is justifiably proud of what he’s achieved with this Fordson.

The Fordson was being sold by a Kent-based collector who had plans to create a ‘rat rod’ from it but, for reasons unknown, this hadn’t gone ahead. It had, however, spent its entire working life in Kent, mainly as a site tanker/refueller at Manston Airfield, on the Isle of Thanet.

This is likely to have been a low-mileage duty but, given that Manston essentially has the sea on three sides, it’s not the best environment from a metal-preservation point of view! After Manston, it moved just a few miles down the road to Ramsgate and Jentex Fuels; a family-run business supplying oil for heating and industrial purposes. How long, or for that matter if, it worked there isn’t known, but it did spend some time at least painted all-over white, and parked at the company’s entrance as a (not-very) mobile advertisement.

For this role, it was tidied up externally and, from 20 yards, it actually looked pretty good. It was, however, a cosmetic-only job done purely for looks; a bit like a film studio set, but definitely one with the structural integrity of a Crossroads set in 1976 rather than Coronation Street in 2021!

Much of the cab’s structure was formed using “chicken wire and filler” and Paul reckoned that, as obtained, it wasn’t even safe to sit in, and certainly wouldn’t have survived long at all on the road…

Oh, and the final 18in of chassis had been chopped off at some point for some reason; something Paul discovered when, on trying to refit the spare wheel carrier, he found that there was nothing to attach the rear mounts to…

As a general rule, Paul doesn’t like renewing cabs – he reckons it removes a key part of a lorry’s originality, so he’ll always repair an original if possible. In this case, however, there really was no alternative, as there was virtually nothing left from the original to attach new material to! Fortunately, good friend and fellow Ford commercial fan, Greg Shadbolt, had an “easily repairable” cab shell that Paul was able to acquire.

An autojumbler based near Malvern had a complete set of ex-military outer panels. However, persuading said gentlemen to part with them took around seven months! Being new-old stock and genuine Ford items these are, though, 100% correct, right down to the unseen reinforcing panels under the front wings.

There was, though, one major parts issue – the window frames are unobtainable. They are, though, distinctive and noticeable, and really need to be correct. The channel-section is the same as that used on the Ford 7V, and Paul was aware of a Guildford-based enthusiast who’d had some made up in the past which he’d used to manufacture frames. But, unfortunately, he had run out of section, and it wasn’t going to be cost-effective to commission another batch.

After trying “various people around the country”, Paul’s only option was to use “the remains of four or five” which Greg Shadbolt had, and make up two on a best-possible-in-the-circumstances basis. Paul isn’t 100% happy with these but, as he put it, “had I not done it, the lorry still wouldn’t be finished.”

A very original tank that had survived due to use storing farmyard diesel provided this project’s starting point.

Other than that, the cab required relatively little work; a few dents had to be removed, along with a few other “bits and pieces,” but that was basically it.

On the mechanical side, the Perkins engine ran, and actually sounded pretty good. All the same, Paul stripped it and fitted new piston rings and bearings. One common P6 fault was, however, present – there was a crack in the cylinder head adjacent to an injector. A tractor-enthusiast friend who has “lots of old P6 engines” supplied a replacement head, but they had to remove and inspect four before finding a good one.

Overall, though, the engine was in good condition and showed few signs of wear, suggesting that, as is often the case with airfield vehicles, the Fordson hadn’t done many miles. The injectors and fuel injection pump were overhauled by Essex Diesels, and a new-old-stock water pump fitted, along with a reconditioned radiator.

Shortened tank in position, with the chassis in the process of being returned to original length. Spare wheel carrier was refitted as an additional guide.

In contrast to the engine, the gearbox was seized solid and, on taking the cover off, the cause was obvious straightaway; it was full of water! However, Paul was able to find a new-old-stock 7V ‘box – ex-military again. The only difference is that the 7V input/first motion shaft is shorter; swapping this from the old ‘box was straightforward. The rear axle was fine, and needed only new seals and brake shoes, and Paul went through the whole steering, suspension and braking system, though little was needed beyond freeing-off and a few routine service-type replacements.

Turning back to the tank now, the first job was to remove its cargo, in the form of a full load of now-stagnant and extremely pungent red diesel; a far from pleasant task. The four-compartment tank also needed shortening to three, to suit the Fordson chassis. Paul could have done this himself, but it would have taken him a disproportionately long time, whereas a good friend Mark runs specialist tanker repair business Tanker Modification & Repair, on Canvey Island, and has all the large-scale folding machines and other special equipment needed. Before it could be worked on, though, the tank had to be given the exact-same clean-out and neutralisation treatment as an in-service unut, to ensure every last trace of inflammable fuel vapour and other nasty gases were removed.

The cab in primer, awaiting top coat.

The tank was shortened as required – work which would have taken Paul, quite literally, weeks was routine stuff for TMR, completed swiftly, and once the tank was the right length for its new installation, Paul took the chassis-cab unit for a trial fitting, and to ascertain for certain by how much the chassis needed extending. This confirmed that reinstating the missing 18in would be sufficient and, as tank and chassis were at TMR and again work of this kind was second-nature to them, it made sense for them to make and fit the new chassis rear-end.

The chassis-cab and tank were then returned to Paul’s premises for final-fitting, prepping and painting. Almost immediately, though, a snag was discovered; one of the tank supports was fouling a rear spring mount. The mounts form a crucial part of the tank’s structure, and moving the offending one was, therefore, out of the question. However, because the tank compartments aren’t exactly the same size, the supports aren’t spaced evenly along the body. Therefore, if the tank was fitted the opposite way around, the mount positions would be fine.

In top coat. Tank was later removed and painted separately.

That, though, bought with it an additional issue; it meant that the shaped outlet pipes under the tank would then be facing the wrong way, and had to be reformed into, basically mirror-images of themselves. The fabrication and welding work needed to do this was, in Paul’s words, “beyond specialist” but he knuckled down and completed it himself in a weekend; “I’m a great believer in the principle that, whatever problem you may come across, there’s always a way.”

As you can see from the photos here, the results look perfect though the emphasis here is on looks; “I doubt I’d be given a safe loading pass at Canvey Island oil terminal.”

Starting the cab fit-up.

Paul did most of the paint prep work himself, but the actual painting – in two-pack – was completed by a friend with the appropriate facilities. David Harms, of Astra Signs, applied the signwriting and, because the tank had on it the cab number and other ‘ID’ of the vehicle it had been on, these were copied on to the Fordson.

As with most commercial vehicles of the era, there isn’t a massive amount of chrome on the Fordson, but the three strips on the grille are very noticeable.

For two, Paul was able to obtain new-old-stock replacements. For the third, however, he tried a new technique – a local firm to him is able to replicate chrome by spraying it on to a suitably-prepared surface. In this case, the base material was Mazak, with typical Mazak pitting aplenty, so the first stage was to fill all the holes with filler and then prepare a smooth surface.

This was then primed and then, the new chrome finish was sprayed on. In terms of cost there’s little if any benefit over traditional chroming, but the big plus is that the technique can be used on materials such as Mazak that are normally considered too soft for traditional chroming. Paul was very pleased indeed with the result and, given that the sprayed chrome strip is indistinguishable from the chromed chrome strips, we can see why!

As already noted, the completed tanker made its official preservation debut at this year’s Classic & Vintage Commercials Show at Gaydon, where it was extremely well received. Paul is, understandably, very pleased with what he’s achieved, though he freely admits that, with a top speed of around 40mph and, thanks to that Perkins engine, an extremely noisy cab, the Fordson isn’t particularly pleasant to drive. Further appearances are expected next year, and it’s certainly one to look out for!

For a money-saving subscription to Classic & Vintage Commercials magazine, simply click here