A unique AEC Mandator saved from oblivion

Posted by Chris Graham on 31st August 2023

AEC wasn’t considered a ‘heavy haulage’ specialist, but that didn’t stop this Mandator from changing those perceptions, says Ian Shaw.

Mandator usually thought of in artic tractor unit firm.

AEC’s history is way marked by seemingly contrasting classes, from passenger transport, to heavy-duty military applications and then the very core of general haulage – particularly with eight-wheelers – and the move into artics, before being swallowed up by British Leyland.

Loaded and ready to go.

The London General Omnibus Company (LGOC), which had been founded in 1855 to amalgamate and regulate the horse-drawn omnibus, began producing motor omnibuses for its own use in 1909 with the X-type. In 1912, LGOC was taken over by the Underground Group of companies and, as part of the reorganisation, a separate concern was set up for the bus manufacturing elements, and was named Associated Equipment Company.

Tasker 20-ton eight-wheel trailer dwarfs AEC.

AEC’s first commercial vehicle was a Y-type lorry, based on the X-type bus chassis. With the outbreak of World War I , AEC’s ability to produce large numbers of vehicles using moving-track assembly lines, based on American principles, became important for supplying the increasing demand for army lorries. AEC started large-scale production of its three-ton Y-type lorry in 1916 and, by the end of the First World War, over 9,000 Y-type lorries had been manufactured. From then on, AEC became associated with both lorries and buses while, in 1932, the company took a controlling interest in the British subsidiary of the American Four Wheel Drive (FWD) company, and began to use more standard AEC components in those vehicles. Production ceased in 1936, but this association was to underpin some of AEC’s iconic WWII vehicles.

Ballast body is to limousine standard.

From 1941 – when all civilian AECs ceased production – until 1944, AEC produced nearly 10,000 vehicles for the war effort. The 10-ton 4×4 Matador artillery tractor was an adaptation of the civilian 4×2 Matador lorry, exploiting AEC’s experience with the FWD venture. The Matador was used for towing guns, such as the 5.5in medium gun and the 3.7in AA gun. A 6×6 version – which was actually a Marshal fitted with Matador axles and wheels, but almost always still called the Matador – saw service as an RAF refueller. In the post-war years it was these characteristics of strength, durability and plain over-engineering which military designs demand, that was to set AEC’s persona in the haulage sector.

Attention to detail is stunning.

It was the proven 9.6-litre and 11.3-litre engines that allowed AEC to dominate the eight-wheel rigid and drawbar market, so why not the heavy haulage sector?

The smaller engine had a gross output of 125hp at 1,800rpm. which compared with the 150hp output of the larger engine at the same speed. This 11.3-litre was rated at some 505lb/ft of torque; impressive for its size. Even more impressive was that it was fitted into a short-wheelbase Mandator four-wheel chassis and a rare factory-special at that, the like of which AEC didn’t generally profess to undertake. This individual specification, with extended rear chassis carrying heavy haulage capacity towing jaws front and rear, came about at the behest of one man, Alf Mayle.

Taller axle ratio gives decent modern pace.

Military strategies

Scammell dominated the heavy haulage sector in the 1950s, many companies had started their heavy haulage careers with ex-army wartime Scammells and US Diamond-Ts (or Pacifics, in the case of Wynns) and, although Scammell had championed the artic for tank transporter use, the Diamond-T was more usually a ballast-body tractor with full, three-axle Dyson or Tasker drawbar trailer. Alf Mayle drove for Westfield Transport from 1952 until his retirement in 1978, and the Mansfield-based general haulier, which took its name from its Westfield Lane base, could trace its history back to 1933.

Front towing jaw, essential for push-pull or double-heading huge loads.

The company, like so many others, had turned to heavy haulage in the post-war years, and embraced Scammells as its vehicle of choice for these tasks. Alf Mayle, however, wasn’t a fan, citing that, by the late ‘50s, the Scammell product had changed little from the wartime designs. Having driven AECs in the army, he put this forward as his choice for his replacement wagon for 1958. The exact conversation between Alf and his transport manager isn’t comprehensively documented, but we can imagine the gist of it!

Original Westfield livery reproduced exactly.

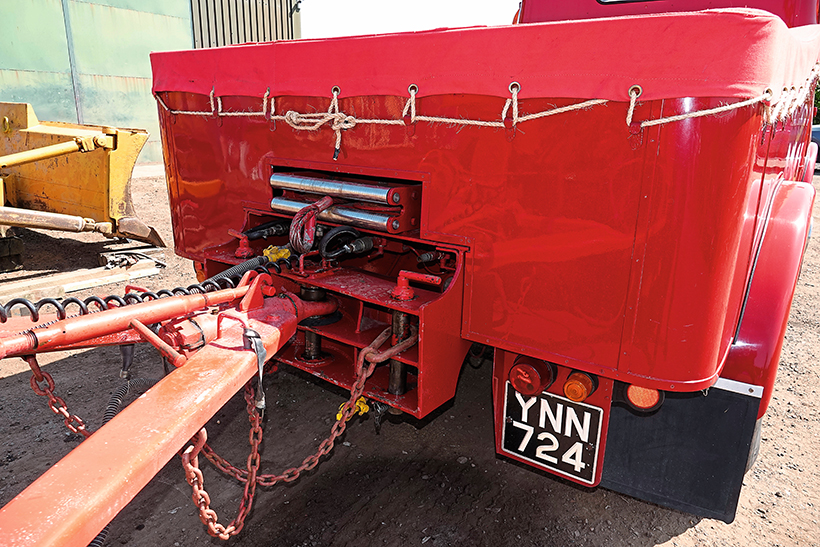

Then into the picture came the local AEC agent, ACV of Nottingham which, keen to get a sale, managed in turn to persuade AEC to build a Mandator Mk3, with an 11.3-litre engine, chassis extension, heavy-duty towing jaws at each end for push-pull work and a 15-ton line-pull capacity Darlington winch. To this a ballast body was added. It was aluminium, due to a wonderful example of British road haulage legislation. Road tax was calculated on unladen weight, so the aluminium body dropped the 6-ton 13-cwt Mandator into a lower taxation class, yet it never left the Westfield Lane yard at less than 12 tons GVW, with its slabs of boiler-plate ballast!

Cab interior – probably not this good in 1958.

Either Alf was keen to prove his faith in the Mandator, or Westfield’s accountant was interested to see its worth but, whichever, its first job was taking a 30-ton Ruston-Bucyrus excavator down to Newton Abbott in Devon at around 55 tons all-up. A common load for the Mandator and its (then) three-axle drawbar trailer – which itself tipped the scales in excess of 12 tons unladen – were 35-ton Lancashire boilers. Here the winch came into play. Something of a hangover from the war, the ex-army tank transporters and recovery tractors on which so many heavy hauliers cut their teeth were always equipped with large chassis-mounted winches.

AEC hallmarks, switchbox and big four-spoke wheel.

During factory installations they were essential. The pulley block-savvy operator could slowly and carefully manoeuvre either the trailer itself – in a similar manner to today’s self-propelled multi-axle bogies – or the machine upon its cast-iron bed. The Lancashire boilers were side-loaded onto the low-loader trailer by rolling them on railway sleepers, having rigged the winch rope all the way over the top. Alf Mayle’s party piece was to pace out the distance to be winched so that once on the trailer, the boiler’s manhole inspection cover was bottom dead-centre, its flat face meaning the boiler rolled no further while being secured.

No hydraulic scissor-ramps then, it took hours of work to unload.

Another one of its regular loads was huge, American-made Calio hosiery knitting machines, producing stockings at Foister, Clay & Ward, a Mansfield-based company. These 60-foot long units were to become Westfields core business from 1948, and were regularly transported by Alf and the Mandator with a three-axle drawbar trailer from Liverpool docks.

Darlington winch (rope exits above jaw) heavy haulier’s best friend.

Family and firm

The Mandator’s family history is rooted in Alf’s 14 years of driving it for Westfield Transport. Alf’s son, Dennis, started in 1961 as second-man on the AEC aged 21, and grandson Steve rode in it as a boy of eight years old. However, in 1964, Westfield Transport was bought out by Pickfords, further adding to the company’s near-monopoly of the heavy-haulage sector which had begun on the skewed playing field brought about in the BRS days. Pickfords’ doctrine was to operate vehicles for 10 years, and the Mandator had already seen 14 years on the road, so it was consigned to work as a yard-shunter. This led to a gradual decline in its condition, with it generally being knocked about and unloved, until it was sent for disposal to Havant and presumed scrapped.

Tasker trailer’s details are fantastic.

Then, purely by chance, Alf’s grandson Steve, by now a haulier in his own right and latterly commercial vehicle restorer of note, saw some photographs of the Mandator at a steam fair that had been taken in 1990, and the hunt was on. It was owned at the time by James Louther who exhibited a pair of steam ploughing engines at such events, and Steve set out to buy it. This finally came about only when the vehicle was no longer in running condition – the differential had suffered a broken pinion gear, the resulting damage rendering the whole final drive unit as scrap. By 1995, the Mandator languished in a yard in Uckfield, East Sussex.

Steve took his grandfather Alf down to look at it, carrying a spare battery on his truck and the Mandator started up at first try. The deal was done and Alf was re-united with his beloved AEC. Then began the painstaking, five-year restoration. The shattered diff proved to be a blessing in disguise as Steve replaced the original 7:1 crown and pinion set with a taller 6.25:1 unit. For modern traffic this gives the Mandator a more suitable top speed in excess of 35mph, where it would not reach 30 previously, but the bottom gear of the four-plus-crawler transmission is now essential to move off. Being a full crash gear – rather than a constant mesh as are the upper four – Steve describes the gear change quality as being a little bit tricky, or at least some words to that effect!

The Mandator was in a poor state. It had suffered badly with panel damage during its days as a yard-shunter and then the inevitable advance of corrosion meant both the cab and specially-built chassis were in need of a full rebuild. The engine too, transmission and braking system would all be totally rebuilt to Steve Mayle’s exacting standards. However, around halfway through the restoration came the worst news of all, Alf Mayle had passed away. Steve describes it as the bitterest pill to swallow, Alf had seen his truck re-discovered, but sadly not its return to the road. That would come in 2001, when it would be widely seen on the show circuit; a regular at Newark, just a few miles down the road from Steve’s new base and not far from its native Mansfield.

Trailer tasks

None of the trailers the Mandator would have operated with at Westfield Transport were still in existence, so Steve set about finding a suitable alternative. Just as the heavy-haulage men used ex-army trucks, they also would press into service ex-army trailers too and, being former tank or plant transporters for the most part, they were suitably over-engineered. This Tasker low-loader would more likely have carried a bulldozer or excavator for the Royal Engineers than armoured fighting vehicles.

Caterpillar D7 hails from 1943, but you wouldn’t know it.

Its army designation of simply ‘Trailer eight-wheel 20-ton’, does little to describe its build and indeed its presence. Taskers began building steam engines in the early 1800s, in Andover and, in the 1930s, it became a leading manufacturer of agricultural implements. Bought by Craven in the 1970s, the original company became part of Irish trailer manufacturer Montracon in the 1980s, while former employees began Andover Trailers which makes general haulage and low-loader trailers today.

Steve purchased this one from Martin Cavanaugh, who delivered it with his WWII AEC Matador artillery tractor, which must have made for quite a sight. Steve set about a full, nut-and-bolt restoration, the trailer had to match the condition of the restored Mandator and, once completed, it was used to take a dragline excavator to shows, but its current load is of the same vintage. A 1943 Caterpillar D7 bulldozer, the type that saw plenty of military service from general duties in road-building and preparing river crossings, to acting a beach recovery tractors during amphibious landings with both US and British forces.

Steve even has a hefty Hyster winch to rear-mount; a common fitting where the ‘dozer would head to the top of the beach and winch-up stricken GS vehicles, often two or even three at a time in ‘daisy chain’ fashion. This one has benefited from later modifications in civvy street, with the so-called ‘hard nose’ front end and full hydraulic power for the blade – originally it would have had the gantry and cable system. The blade itself has to be removed for transport since, at three metres wide, it would require abnormal load escort and documentation. Steve has an answer to this problem, however, and is working on a rotating mount, to angle the blade sufficiently that it brings it within the trailer’s overall width.

It really is the cherry on the cake, and the whole outfit makes for an impressive sight on the road, also emphasising just how diminutive the forward-control two-axle Mandator is with such a trailer, compared to the 6×4 bonneted Scammells or Diamond-Ts which would have been the more common tug for such a load. “You don’t see many like this on the road,” says Steve modestly, as he climbs into the cab to head for the Newark Showground. For ‘don’t see many’ you can comfortably substitute the word ‘unique’. Alf Mayle’s insistence upon – and faith in – the AEC certainly wasn’t misplaced 65 years ago. It’s still changing perceptions to this day.

The author wishes to thank owner Steve Mayle for access to his comprehensive archive on the Mandator and Westfield Transport’s history.

This feature comes from the latest issue of Heritage Commercials, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

Super Stationary Engine Crank-Up!

Next Post

Classic bus enthusiasts’ treats in Winchester on way!