Power and glory

Posted by Chris Graham on 12th March 2020

David Lemonius has been a County man for many years, and this interest has culminated in the restoration of a fine Super 6. This is his story about that tractor; at tale of power and glory!

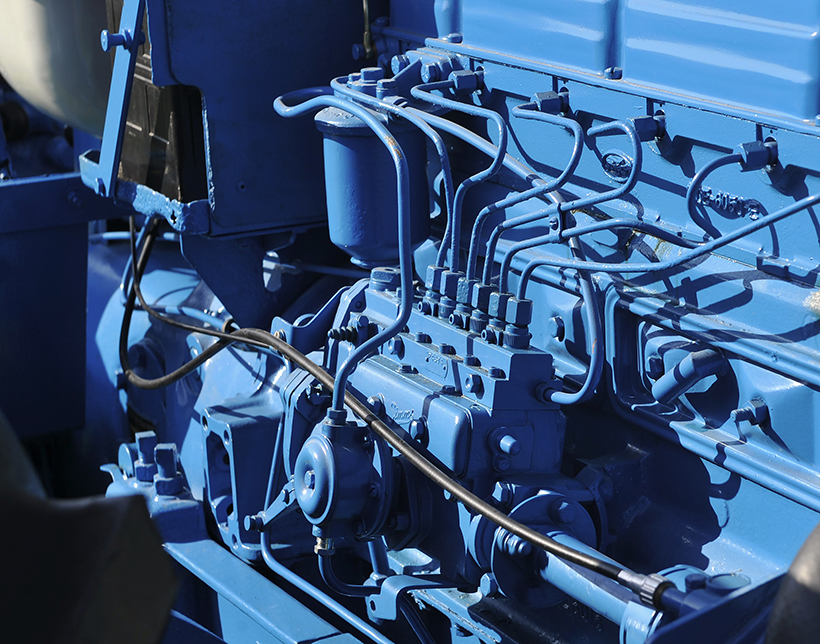

Power and glory! David did all the panel spraying on his County Super 6, but the rest of the tractor was painted by hand. Cellulose paint was used throughout.

Restoring the 1965 County Super 6 you see here was a real challenge and, even now, there are a couple of details that still need to be sorted. It wasn’t hard from a mechanical point of view – I’m more than happy working with this sort of ‘classic era’ tractor – but it was the sheer extent of the project that tested me most.

I have a mechanical background, having worked for a few years as a tractor mechanic with Ford/Fordson agricultural dealership, WJ Cooper & Sons, in Buckingham, after leaving college in 1963. That’s where the seeds of my interest in County tractors were sown; there were a lot of large farms in that part of rural Buckinghamshire, so powerful County machines were a popular option in those days.

Island roots

But my roots were in the Isle of Wight, where I grew up, so returning there to work was my next move. I spent 15 years in the farm machinery sales, maintenance and repair sector, then switched to one of my other passions – boats. I got the opportunity to rent a boatyard in Yarmouth, which I ran successfully for the next 15 years.

This rebuild has been immensely satisfying, but it was certainly very labour-intensive and David has vowed not to tackle another like it!

By the time I reached my mid-60s, I felt like I needed another change of direction, and to start slowing things down a bit. Getting into old tractors seemed like the obvious thing to do but, just as I’d moved on from the boatyard, my son returned from the Merchant Navy, bought Needles Pleasure Cruises and asked me if I wanted to help with that. The business runs boat trips from Alum Bay to the Needles and, as I have a Boat Master license for carrying passengers, I got straight into running those trips on a more-or-less full-time basis.

This, of course, meant that I wasn’t able to spend much time on the tractor side of things, and my plans to set up a small business repairing and restoring classic tractors had to be put on hold. It wasn’t until 2007 that I finally got to restore my first tractor, which was a 1959 Fordson Dexta, and I followed that with a 1942 Standard N. These were both complete, nut-and-bolt renovations, and I really enjoyed the process in both cases. It’s the engineering side that really interests me, together with fault-finding. In some respects, I’m actually sorry when a restoration is finished; it’s the engineering challenge that fires my enthusiasm. If I’m honest, I don’t have so much interest in actually using a tractor once I’ve restored it, and what drives me is the prospect of the next project.

Super 6 arrives

The Super 6 came to me in 2007. I’d been looking for a County to take on as a project for a while, and eventually found this 1965 model (one of the last to be made) at Robert Fearnley’s in Norfolk. It was in part-restored condition, with the wings and other panels having been shot-blasted and finished in primer. Coincidentally, Robert also had a Roadless 75 in stock, so I did a deal and bought them both. I still have the Roadless and use it for working days but, in terms of restoration, I’ve barely touched it.

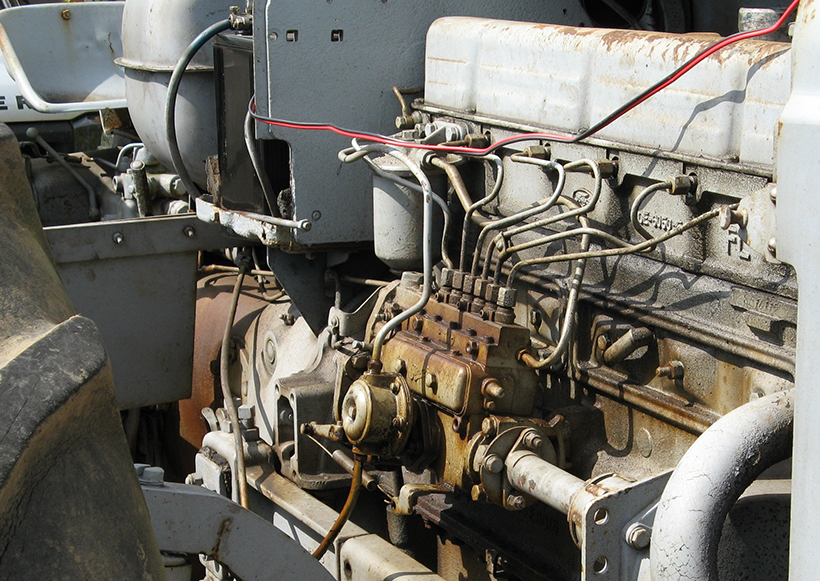

The tractor arrived on the Isle of Wight in quite a state. Bits were missing, a coat of primer had been badly applied and the engine required major mechanical work.

The County turned out to be a much bigger project than I had been expecting and, knowing what I know now, I probably wouldn’t tackle anything similar again. Regrettably, the job was ultimately made worse by the fact that the tractor had to stand outside (under a cover) for about four years, before I had any spare time to get started on its restoration.

It soon became apparent that the tractor was actually in a pretty rough state, mechanically speaking. Apart from the badly-primed panels, I started finding that it had been fitted with metric nuts and bolts all over the place. This added weight to my idea that is a tractor that had been imported back into the UK after a working life abroad (although I’ve not been able to confirm this yet).

Work on the engine involved fitting new pistons and liners, replacing the shell bearings, and having the diesel pump reconditioned (David wasn’t able to tackle the latter himself).

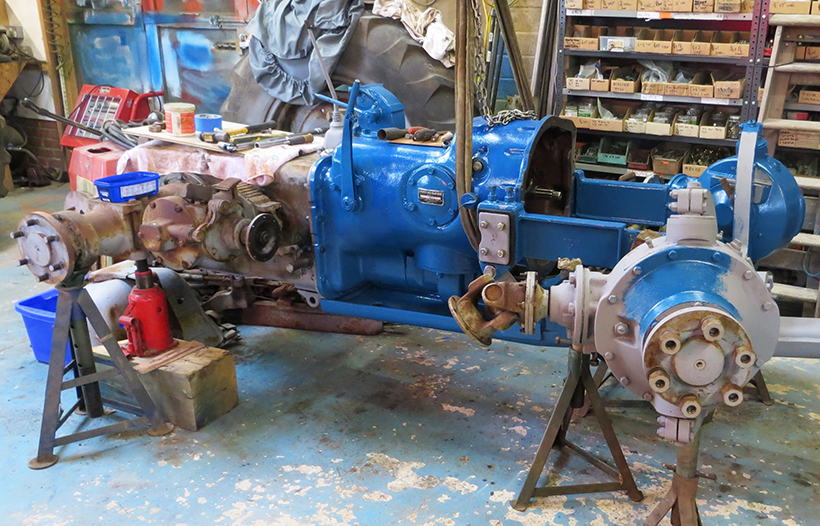

Gearbox trouble

I’d been warned that there was a bit of a problem with the gearbox, and that it wouldn’t stay in one of the ranges. But, when I removed the side plate to have a look inside, I couldn’t believe the mess I found. Somebody had been messing around inside there with a welder! Fortunately, I had an old Power Major at the time, fitted with a decent, single-clutch gearbox, so I was able to scavenge the bits I needed out of that.

Although the engine was original and ran when I got it, it was obviously very tired and required significant work. I fitted new pistons and liners, replaced the shell bearings, and got the diesel pump reconditioned. Now it runs beautifully. Other mechanical jobs included replacing some worn bearings in the back axle – an old diff from a Super Major provided the parts I needed.

David is a great fan of the relative simplicity of the four-wheel-drive system fitted to the County Super 6. He thoroughly enjoys working on tractors from the ‘classic’ era.

As far as the electrics are concerned, I fitted a new wiring loom, lengthening it where necessary to fit the County layout. The only problem that I still have to deal with concerns the temperature gauge. The standard length of the capillary tube that came with the replacement I bought isn’t long enough, so it’s not working at the moment. Currently, I use a laser gun to keep an eye on engine operating temperature, which is fine for the time being. Other electrical items that needed to be replaced include the headlights and the ignition switch.

Pressing issues

I did all the work myself in this restoration, apart from a few specialist tasks, such as re-chroming the drive shafts. I have my own lathe, so I’m able to machine components when necessary, and a hydraulic press, although the latter wasn’t large enough to press the ends of the drive shafts. I’m also a reasonably experienced welder, although I’ve given up my acetylene bottles now as I simply wasn’t using them enough. Now I rely on an electric welder, but also have propane and oxygen tanks to provide a flame if I need one.

The County Super 6 was a big performer in its day. This one has been meticulously brought back to life, and is now for sale.

The original, fiberglass bonnet needed some repairs but, with my years of experience in the boat industry, I was quite happy tackling that work. The only other thing that I’ve not been able to do is to find the correct exhaust manifold. The one that’s currently fitted is from a truck application, and extends backwards, rather than running down and under the chassis member, as the original did. However, I think I may have tracked down the correct manifold, which will then mean that I can get the rest of the exhaust fabricated to the original design, although this will depend on finding somebody with the equipment needed to bend the pipe correctly. I gather that the machinery needed to do this is getting scarce nowadays, but have been advised that a traditional ship builder’s yard might be worth a try.

As for the paintwork, I did all the spraying myself using a conventional, cellulose product. However, I opted to hand-paint the chassis – applying two coats of primer and then three coats of top coat. I didn’t set out to create a Concours-winning example, but simply wanted a good, ‘working’ finish, and I think I achieved that.

Finished at last

Having only recently finished the County restoration project, I haven’t had a chance to really use it yet. In fact, the short journey needed to take the photographs for this feature, was the first time that it’s actually been out on the road! Before that, all I’d done was move it around on the drive, just to make sure that all the gears, and the brakes, were working.

The turning circle on the County Super 6 is notoriously poor – one of this tractor’s very few weaknesses.

Overall, I’m very pleased with the results I’ve achieved, and think that the Super 6 is a great tractor. One of the factors that attracted me to the model in the first place was the engine. I love six- and eight-cylinder engines, both in terms of the power they deliver, and the sound they make. I think that, back in the day, this was one of the aspects that set the County machines apart from the rest; an aspect that made them a bit special. They could do things that their contemporaries simply couldn’t. Granted, 80 or 90hp is nothing special these days, but it certainly was when these tractors were new, back in the 1960s.

But, as well as the power, there’s a really satisfying, mechanical refinement to them, too. I can remember carrying out PDI inspections on 954 and 1004 models and, in those days, we used to stand a thruppenny bit on top of a running engine, and it wouldn’t fall over. This, I think, is pretty impressive for an agricultural engine fitted to a working, utility vehicle. I also admired the engineering simplicity of the four-wheel-drive system as well as the inherent reliability the County tractors delivered. However, as power levels steadily increased, mechanical weaknesses within the Ford-designed transmission system started to be exposed, leading to kore problem.

The fuel tank is original, the fiberglass bonnet needed repair and new wings have been fitted.

County quality

The quality of the engineering certainly played a big part in keeping the restoration of this tractor a relatively simple and straightforward process. The only aspect that became a challenge for me was the laborious cleaning and preparation that was required by virtually every component. Undoing the previous renovation work done by a previous owner, certainly added significantly to my frustration levels, and to the time spent on the project. Discovering mud beneath hastily-applied primer is quite a dispiriting business especially if, like me, you find parts preparation a real chore!

We have a pretty decent old tractor scene here on the Isle of Wight, with a number of popular road runs and shows. I get involved with non-competitive ploughing, and also attend a few tractor events on the mainland, from time to time. I’m very limited though, with regard to summer shows, because of my commitments to my son’s pleasure cruise business.

The temperature gauge (left) isn’t currently working; its capillary tube is too short.

As well as the County, I currently own a 1971 Ford Force 4000 which I bought about a year ago here on the island. It’s in need of a full restoration after spending many years working hard in a boatyard. I also have a 1965 Pre-Force 4000 that’s fitted with a loader (currently used as a utility, working tractor here at home), a 1965 Pre-Force 3000 and, of course, the 1972 Roadless 75.

Favoured classics

I haven’t been tempted back to the really old machines because, overall, I think I prefer tractors from the ‘classic’ era. Those from the 1960s and ‘70s are what I feel most comfortable with; I’m familiar with their design and engineering, so am happiest repairing and restoring them. However, one slightly dark cloud on the horizon – from a tractor point of view – is that we’re about to move house, and I won’t have as much space at the new place as I do now. This means that I have some hard decisions to make, as my tractor fleet will have to be rationalised. Fortunately, I have some friends who have offered me storage for equipment and some tractors, but I’m certainly not going to be able to keep them all.

The Roadless 75 is probably my current favourite but – sadly – it’s one of the machines that’s destined to go, and I think I already have a buyer lined up. I have a connection with that tractor; probably more so than I do with the others. I can remember going on an official Roadless demonstration back in the late 1960s, when the late Ven Dodge was the UK sales manager. I was impressed by the Roadless 65 then and subsequently bought one, and have been interested in them ever since. But I also have a real soft spot for my Pre-Force 4000. It’s a really handy little tractor, offering a great combination of power and manoeuvrability.

I still aim to continue restoring tractors after the move; I’ll have the room to work on one at a time. But I think that, realistically, I’ll have to restrict myself to less involved projects. Alas, tackling big projects like the County Super 6 in the future will probably be a step too far.

David’s done a superb job with the restoration of this tractor.

You can subscribe to Ford & Fordson Tractors by clicking here