Pre-war Morris Series II beautifully restored

Posted by Chris Graham on 16th June 2022

Brian Culpan tells the story of a mysterious, pre-war Morris Series II that’s been beautifully restored by its current owner.

The magnificent Gown van, tall, elegant on a swb chassis base.

The story goes that it was last used as a milk float for a short time by a local farmer/dairyman, Henry Hanson. Although not really suited to the task since such tradesmen prefer a van with open sides to give quick access to the crates enabling those nimble enough to grasp three pint bottles in each hand! Or, at the very least a van with its rear doors removed. The Second World War broke out in September 1939; and soon the van was taken off the road, and put away in a barn – and never came out! Having worked for less than three years it would have been in good condition.

Father and son team at Hardy classics – Andrew and Patrick.

Years later, in the mid-1980s, Gerald (Gerry) Walker of Morecambe, came across it and could see that it was an extremely rare vehicle and had the potential to become part of his collection of old vehicles. Having bought it, he got permission from George Walling, a chicken farmer, to keep it in an open barn at his Hornby Farm, in Forton, near Garstang. Gerry enthusiastically began to take the van apart to do a ground up restoration, unfortunately he did not get very far, for some reason. Consequently, the van was neglected, although not stood outside, time and weather conditions caused rapid deterioration: resulting in the flimsy rear wooden body and hardboard panelling to rot and fall apart (the complete offside body side had fallen off). The van’s once glossy brown paintwork had faded to a very dull shade, but the yellow lettering acclaiming the milk was of the highest quality remained. Sadly, Gerry passed away in October 2015 before he could complete the restoration – but he had saved the Morris although it had deteriorated somewhat.

The finished cab awaiting a steering wheel switch.

In January 2016, his collection of old vehicles was sold off, the Morris went to a new owner, Gary Cadwell of Banks near Southport, he is an old vehicle enthusiast and supplies vehicles for TV and film-work. At the same time Gary bought a Ford Pilot from the farm, when new this had been a stepside pickup; part of a cancelled oil company order, destined for the Far East and therefore LHD. Fosters of Preston were commissioned to replace the body with a coachbuilt van one; suitable for delivering day-old chicks. Gary carefully stored the old Morris van but didn’t work on it.

Richard Gorman busy applying the traditional hand-painted sign-writing.

When the Morris was again up for sale, Paul Budgen of Southport, another vintage vehicle enthusiast, chose it because it was pre-war and of similar construction to previous cars and vans he had experience of restoring. Delighted to know that it came from Gerry’s estate; he was determined to restore it in memory of his good friend of over 40 years – this would be a brave restoration – and should be, given enough time and money, it could be possible!

Missing front end restored, flat, frosted glass headlamps, new wings and bonnet, offset engine is noticeable.

The remains of the Morris were in a dreadful state – everything needed attention; either to be replaced or refurbished. The fabric roof had disintegrated years ago, allowing dampness to attack the rear bodywork from the inside. The forward roof fabric was wearing thin over the laths, so curved aluminium was overlaid to shelter the cab. The full-length fabric roof had been painted white, at some time. The steel panelled driver’s door was severely corroded; peppered with holes, the sign-writing was barely discernible. One complete bodyside had fallen off due to rot in its framework. All four tyres were absolutely bald; possibly indicating a hard, high mileage, even if its working life had been short. However, during the war, new tyres were impossible to buy; the natural rubber to make them came from Malay – a war zone. So, secondhand tyres were in strong demand, many owners who had laid up a vehicle for the duration, sold their good tyres, but the Government insisted that the wheels must be part of the deal. The Morris may have had its good tyres sold; replaced by those bald ones.

What the elusive chromed road wheel centres look like – four are needed, anyone got four spare?

At sometime, someone did add a small amount of new body framework to support the missing side and clad it with more durable plywood – amounting to about a day’s work. Unfortunately, there has never been any sign of the old number plates.

Paul wanted to do as much of the work as possible to keep costs under control and also because he enjoyed this type of work. However, a craftsman who normally restored elaborate, traditional Gipsy-style caravans, hand-crafted most of the new ash framework.

Curved front roof is supported by many spars – reminiscent of traditional Romany Gipsy caravans.

There was very little of the front end in place; no bonnet, front wings, or radiator and grille. Also the engine and gearbox were out but present. At the rear, a wooden batten, crudely nailed above the doors, secured a piece of tarpaulin stretched along the roof as temporary protection against the weather. The first step was to completely dismantle the van. Then starting from the ground up; shot-blasting all five wheels and powder coating them; fitting new cross-ply tyres and new inner tubes. The bare chassis was cleaned and painted, the petrol tank repaired and fitted with a new sender unit. Brakes relined, new seals fitted to the wheel cylinders and master cylinder.

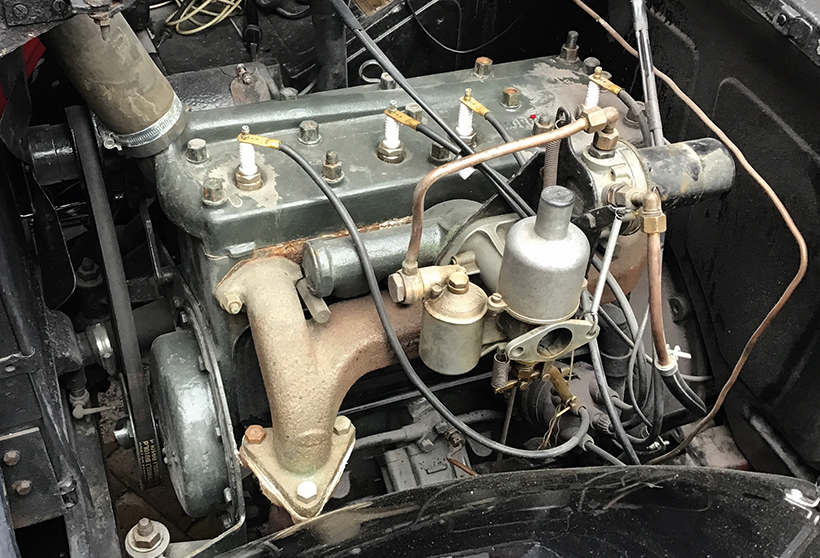

The interesting nearside of the engine.

Paul took a good look at the seized engine and concluded it would be a heap of trouble to put in working order. Fortunately, he had a friend, Ray Tomkinson, who did a lot of film-work with old, period vehicles, one of these was an example of the later, follow-on model, the Y Type. To make it more peppy and reliable, its engine and gearbox had been replaced by a far more modern power unit and gearbox, so, the Y’s engine and gearbox was available. Interestingly, the SII had a wet clutch (similar to that of a motorcycle of the time with a cork insert driven plate) the Y Type had progressed to a dry clutch. The SII engine would not have worked with a dry clutch bellhousing; it would have needed complicated machining to fit an essential oil seal behind the flywheel, it was just easier to replace the entire power unit/gearbox lineup. Unfortunately, the ‘new’ units needed to be lightly overhauled. A re-wired dynamo with new cut-out box and ignition switch were bought and fitted.

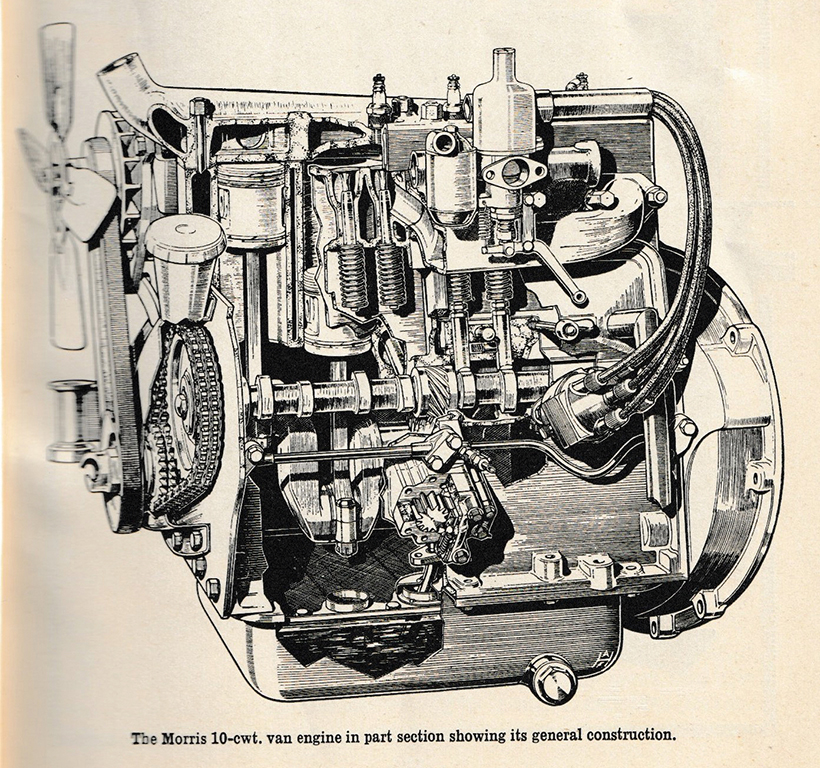

Cut-away engine view.

The rear axle was ok and only needed new rubber bump-stops, but the front axle’s kingpins and bushes needed replacing. Much of the van’s T&G timber floor boarding was missing; so the entire area was re-boarded. The cab doors were re-skinned in aluminium, new rain channels and drip rails added.

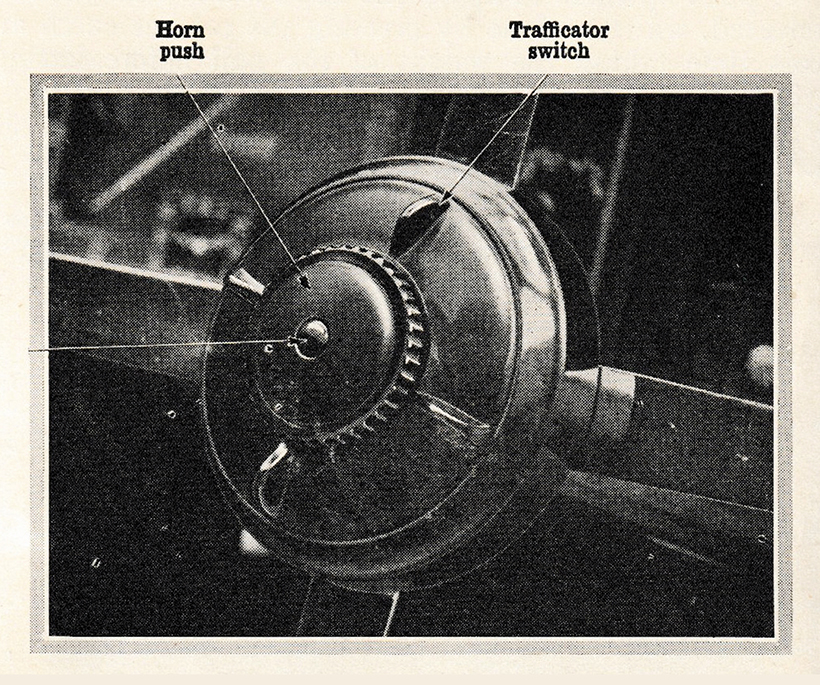

Handbook picture of the missing steering wheel switches.

The fabric roof was replaced; along with all guttering and drip rails. New window glass was fitted (but the driver’s door window has recently developed a small crack). The original door cards have been copied and new ones fitted, also the one missing window winder replaced. The radiator only needed to be re-cored; its surround re-chromed, but the two front wings had to be built from scratch. The bonnet proved to be a problem as no replacement could be sourced – so one was made by ‘cutting-down’ an old Morris saloon one, a complication was that part of the front wings are integral with the sides. Four new retaining catches were bought. Replacement number plates were added – the old style font and digits carefully copied by the sign-writer. As a final touch; a new, entire, exhaust system was fitted.

Ready for transportation to the paintshop.

This extensive project was nearing completion; all the mechanical work, had been done, however the new body needed painting, a task that Paul felt would be better done by an expert. So Andrew offered to take on the project and complete the restoration – this would still be expensive! Normally the spare wheel was carried on a cradle, at the back, under the load floor. To avoid it being exposed, the restored bodywork went across the carrier and had been fixed in place to cover it. Andrew thought it could be improved on, and so it is now hidden behind a new curved, hinged cover, secured by budget locks. Initially, Andrew thought since the bodywork was a composite; made up of timber, steel, and aluminium, that would test his spraying skills – did he still have the knack of achieving the perfect paint finish?

Body frame has been started.

In the end it was taken by the in-house transporter to ‘Premier Truck Hire’ in Blaydon, Tyne & Wear, they’re usually asked to work on new HGV’s. The eye-catching two-tone paint scheme is in keeping with the business style and was already featured on the company’s transporter truck. It is cream and a Morris maroon combination. The paint shop supervisor, Carl, did the work himself using two-pack modern paint (originally the van would have had coach enamel paint applied by hand). The genuine, hand-painted sign-writing was done by skilled craftsman Richard Gorman of ‘Precision Painting’. The livery is that of daughter Anna’s high class handbags and shoes business ‘Classic Coutre’. The restoration, as it appears today, was completed in October 2019.

Side panels are now in durable plywood – replacing the original hardboard!

There are a few small items still needed, that are proving elusive. The first is a steering wheel centre combined switch for the trafficators and horn push (the dash mounted switch is a temporary measure). Secondly a set of four chromed road wheel centres.

At some point in its life, the Morris was re-registered with the DVLA and given a replacement age-related ‘plate SSV 498 from an unused Kinross Series (the authority is in a sparsely populated area of Scotland and didn’t need to issue any three-figure registrations). The original registration had been lost or sold. Additionally, since during the mechanical rebuild, the engine, clutch and gearbox combination had been changed for later units from a Series Y (featuring a dry rather than wet clutch) so, someone thought it prudent to change the V5C model designation to Y – although it looks like, and is still a Series II.

Ready for painting.

My sincere thanks for supplying invaluable help with this article go to Andrew and Patrick Hardy of Hardy Classics, Gary Cadwell and Paul Budgen for both supplying old restoration photographs.

Model history

The new Morris Series II 10cwt marked a significant change in small commercial vehicle design. Since the 12hp saloon whose mechanical parts this commercial used was now in its second version; and had been revised with updated components and given the title Series II – the van adopted the same description (there had been no SI commercials).

In ‘as found’ state of the dash and steering wheel.

The Series II 10 cwt van had been introduced in August 1935 to replace the normal control 8/10cwt van based on the Morris 12/4 chassis. This new model was the result of some very serious thinking and reappraisal of what a commercial should look like. One of the new ideas was that of a semi-forward control driving position. It provided a far more effective packaging of driver and load. In fact, the wheelbase had been reduced to 7ft 6in – a foot shorter than the preceding model. Also, for the first time, the front and rear tracks were different; the front came from the car range and was narrower than the designers would have liked, but the rear was new because it had to have an offset differential to suit the driveline, so engineers were free to widen it by 4in to 4ft 6in.

Peeling paintwork.

The body volume had been increased to a very useful 128 cu.ft. capacity. Wire wheels with large Magna hubs also came from the car, and in true Morris practice of the time, hydraulic brakes were considered essential. Since a semi-forward control driving position was adopted, to achieve this, the engine was offset considerably (as indicated by the position of the starting handle hole), it gave the driver adequate legroom by allowing his feet to be well forward, under the bonnet, alongside the engine in a metal tunnel. It marked the departure of Morris from using the current saloon’s bodywork to create commercials with very different bodywork but still using the same running gear!

The van as bought by Paul Budgen.

The down side was that very little room was left to accommodate a passenger. A full-width bench seat could be fitted in factory bodied vans but the legroom on the passenger side was severely restricted! Ideal for a youngster, maybe a van boy (aspiring to one day be a driver when older), new to the working world, having left school at 13. Since this type of truck was popular with businesses such as: dressmakers/fashion houses, furniture makers, and small piano or household removals – their driver would need a helper.

So, the Series II replaced the very conventional, normal control, 8/10cwt light van that had been based on the Morris 12/4 saloon range. This car was fitted a four-cylinder side-valve engine of 1547cc; known as the TJ type. The commercials were based on the same mechanicals but used a slightly modified version of this known as the TK. The engine dimensions were: 69.5mm bore x 102mm stroke. A three-speed gearbox (with synchromesh on top and second) was fitted, together with a single, cork-insert plate clutch running in oil – this disc was very big – twice the size of a dry-plate type (to compensate for the loss of frictional area due to the lubricating properties of oil). By omiting any seal; engine oil was allowed to seep past the rear crankshaft bearing and collect in the bellhousing for clutch cooling and lubrication, any excess oil could trickle back to the sump – a simple self-levelling system. A spiral bevel final drive unit completed the driveline. Morris strongly recommended its own brand of oils – Morrisol ‘Sirrom’ made for it by Duckhams!

In the 1930s, Morris Motors were very forward thinking; so hydraulic brakes, by Lockheed, were fitted to all four wheels. The handbrake remaining mechanically operated via cables to the rear wheels.

As with most commercials of the time, only one windscreen wiper was fitted (in front of the driver); the assumption being that a passenger would rarely be carried and therefore need not be catered for. The cab and rear body was traditional coachbuilt; metal panels over a timber frame, its roof was entirely of leather-cloth over wooden laths. Cab doors opened forwards; hinged on their rearmost doorposts, and a step was placed below to aid entry.

Newly fabricated rear wings about to be attached.

The spare wheel was carried on a cradle at the rear of the chassis. A very austere, painted, steel front bumper was fitted but no rear one. Radiator grille was of mesh with a wide chromed surround. Each side of the bonnet contained a vertical row of five, short, cooling louvres; and was secured, on early versions, by crude holding down clips with curved finger grips and exposed small springs positioned – two well down near the bottom of the radiator – that merely hooked into place. The rear mudguards were often simple, curved half-round types, of the ‘mudshield’ all enclosing type. Headlamps and side-lamps have flat, ground glasses, focusing the beam depended solely on accurate positioning of the bulb in the reflector – no correction from ribs moulded into the lenses! The lighting system dipped the nearside headlamp by tipping its reflector and bulb downwards while extinguishing the offside lamp. Focusing of the beam being totally by accurate positioning of the bulb (no correcting prisms in the lens).

However, for a commercial vehicle, it has a comprehensively equipped dashboard; with an ammeter, petrol and oil gauges, clock, inspection lamp socket, and hand throttle. Another modern feature, for the time, is the adoption of flush-fitting, self-cancelling, trafficators with a warning light, were also included in the specification, At the centre of the steering wheel is a small horn push button, around this is a large, round, black disc with four small projections for finger grips. Rotation of this switch operates the Lucas trafficator direction indicator semaphore arms. Above the windscreen are two very small round, button mirrors to check that the arms are in the raised position when required.

Replaced nearside body panel.

However, in contrast to such modern features – a centre accelerator pedal was retained! Advertisements of the time claimed it was: ‘easy to buy, manoeuvre, and to maintain’, and that ‘its capacity was nearly the same as a one-tonner’!

The chassis/scuttle for specialised bodywork was very rare when new, this example is probably the only survivor of its type, something a little different from the more popular factory bodied van and the dropside truck – another type of vehicle rarely seen now in preservation. Most small commercials were delivered in ‘shop grey’ primer for painting in the new owner’s livery once the rear bodywork had been added.

Production ended in December 1939 as the war got started, so very few were built and today, in preservation, it is extremely rare. Easiclean wheels replaced the wire ones early in 1939, the model was replaced late in 1939, by a slightly re-styled version – the Series Y.

This article comes from the latest issue of Heritage Commercials, and you can get a money-saving subscription to the magazine simply by clicking HERE

Previous Post

Stradsett Park Vintage Rally, 2022

Next Post

Bodle Street Green FBHVC ‘Drive it Day’ report