Classic tractor maintenance tips

Posted by Chris Graham on 26th January 2020

Chris Graham meets tractor restoration specialist Ben Phillips to pick his brains about what’s involved in basic, classic tractor maintenance and servicing

Ben Phillips has been repairing and restoring tractors for nearly 30 years, so he certainly knows a thing or two about what makes them tick

If you’re lucky enough to have bought your first tractor recently, then classic tractor maintenance is an ownership aspect that will demand your attention. Tractors, like any other machinery, will fail to function without the necessary care and attention. Good though the mechanical design of Ford and Fordson tractors was, there is a limit to what they can be expected to deliver, in terms of mechanical longevity.

Despite the fact that they were produced as utility machines intended to work long and hard in uncompromising environments, they can’t be expected simply to run and run, especially 30, 60 or 100 years on down the line. So, anyone taking on one of these fine machines must give servicing and maintenance due regard and, in practice, be prepared for the prospect of covering the basics themselves.

Basic maintenance

It’s not always possible – or financially viable – to pack a tractor off to a specialist for an annual injection of TLC, and so the responsibility for basic maintenance in most cases, lies at the feet of the owner. Thankfully, though, we’re not talking rocket science, here. Tractors from the ‘classic’ era are essentially pretty straightforward machines and, accordingly, their mechanical demands tend to be relatively few in number and uncomplicated in nature, even for novice owners with rudimentary DIY skills.

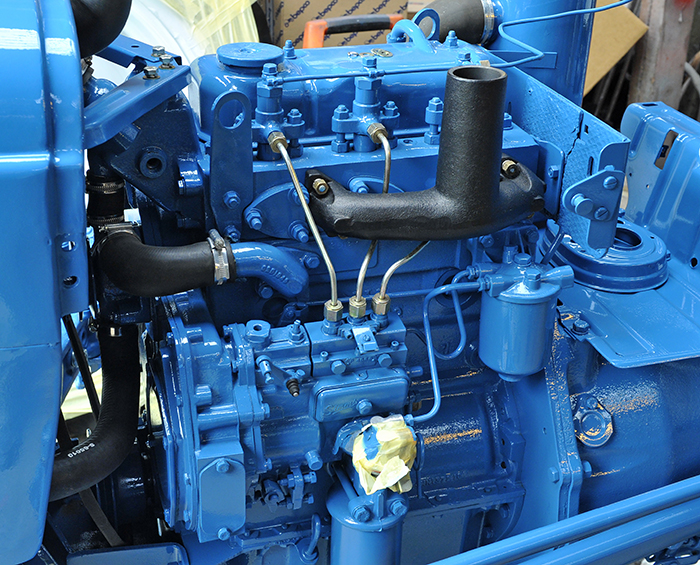

This three-cylinder Perkins diesel engine is well engineered and durable, but its mechanical needs can’t be ignored

So, to learn more about the jobs typically required and – and the tools needed to do them – I set off for deepest Worcestershire, and a meeting with tractor repair and restoration specialist, Ben Phillips (tel: 07760 450567 thetractorlad.co.uk). He’s been restoring tractors for the past 28 years, having started as a teenager working on tractor that his father bought in 1991.

The first point that Ben made was that, by and large, most tractor owners will be able to get by with the sort of normal tool kit that any classic car enthusiast or keen DIYer will already have. “However, given the age of these vehicles,” he added, “it’s sensible to equip yourself with a good set of AF/Imperial spanners and sockets. While you can get by using the more modern, metric equipment, the fit won’t be perfect which can lead to problems is you’re dealing with worn or damaged fixings.”

Because older tractors were built to Imperial measurements, all their fixings are best tackled with A/F spanners and sockets. The metric equivalents are certainly usable, but not quite as precise

Vital oil change

He went on to explain: “One of the most basic, routine maintenance-type jobs needed on any tractor is to change the engine oil, and this can be accomplished perfectly well with a basic set of sockets and rudimentary skills. While wearing disposable gloves, remove the sump plug to drain the oil into a suitably-sized container for responsible disposal, then replace the filter and refill with fresh lubricant; that’s all that’s involved. However, it’s important to refill the engine to the correct level (check the capacity needed), and with the correct grade of oil.

“My advice is to steer well clear of the modern synthetic and semi-synthetic oils,” Ben told me, “old tractor engines simply don’t require this level of lubricant sophistication. Stick with a quality brand of standard, mineral 15/30 grade.” Never forget that oil is the lifeblood of an engine – you skimp on its quality and/or ignore its condition, at your peril. “It’s also worth pointing out that for classic era tractors, the same oil can be used in the engine, gearbox and rear axle,” Ben added.

Sadly, engine oil is overlooked or ignored too often, with many owners paying little attention to its level or condition. Remember that oil has a service life, beyond which it begins to break down and become less effective as a lubricant which, in turn, can lead to needless and greatly accelerated mechanical wear issues inside the engine. Old engines that have endured decades of labour are likely to be mechanically worn causing them to burn oil. There may also be leaks allowing the precious fluid to escape, which is why it’s essential to monitor engine oil level. Typically, on models such as the Dexta, favourite weak spots where leaks can occur include the bottom pulley and the rope seal at the rear of the crankshaft.

Too often ignored

Unfortunately, gearbox and differential oils tend to be neglected to an even greater degree than the lubricant in the engine. It’s not unusual for these never to have been changed during the life of a tractor, with few owners even bothering to check levels. So, it’s fair to assume that oil that’s been locked into a gearbox or differential unit for, say, 45 years, is likely to be on its last legs, and much in need of a change.

Part of the problem is that, unless there’s a problem that results in a leak, gearbox and rear axle oil levels remain pretty much constant so, unless fluid is obviously escaping, owners tend not to bother. The situation is compounded on most Ford and Fordson tractors by the fact that there’s no dipstick for the gearbox or differential, so level-checking isn’t as easy as it is with the engine.

The rudimentary filling procedure involves pouring the oil in until it starts to overflow out of the side level plug that’s found about halfway up the casting, at which point you’ve added enough! But, as a general rule, it makes sense to change all the oil on a tractor that’s new to you; it’s not expensive or difficult to do, and will give you great peace of mind.

Finally, with regard to the engine, the other basic that owners must monitor with care is the coolant level. Overheating caused by coolant loss can prove disastrous, so it’s important that a tractor’s radiator, hoses, water pump and thermostat???? Are all functioning properly, and that the correct amount of coolant is flowing around the system.

Brake failures

The braking system is another aspect on classic tractors that many owners frequently neglect, especially if the vehicles are only used occasionally. fail to keep on top of is the braking system. Because many owners only use their tractors occasionally, brake adjustment frequently gets overlooked. “Keeping brakes correctly adjusted is straightforward,” Ben explained, “but, to do the job properly, you’ll need to get the tractor safely into the air using a jack and then axle stands, so that the rear wheels can be spun freely.

“It’s important to buy yourself a good quality trolley jack and I recommend that it should have a three-ton lifting capacity, which will be perfectly capable of handling the back end of most tractors from the 1920s-1970s period. However, once a tractor’s in the air,” Ben warned, “it’s very important that it’s supported securely on axle stands.

“Leaving it suspended on the jack while you crawl around underneath is a real no-no, as are supporting it on piles of bricks or stacks of wooden blocks. To be honest, the only time that I ever go underneath a tractor that I’m working on, is when it’s sitting on its four wheels, and I can be sure that there’s no chance of a collapse.”

Getting back to the brakes, part of the reason for the neglect in many cases is that wear rates tend to be so low, especially on most tractors that are only driven now and then. As such, the growing inefficiencies of a braking system can sneak up on you. Drivers compensate for the gradual decline in braking performance, and think nothing of it until they’re faced with an emergency stop situation, when the necessary sudden application delivers next to no stopping power.

Old tractors are peppered with grease points, all of which will need to be replenished using a grease gun as part of a routine maintenance programme. Make sure you buy one with a flexible delivery tube

Simple adjustment

Consequently, Ben advises that regular adjustment of the brakes is required on any tractor, to compensate for wear. “To do this is a simple process. All you need is a large, flat-bladed screwdriver to turn the rotary adjuster inside the hub. This is accessed through an aperture in the back of the hub plate, and alterations have to be made with the wheel in the air, so that it can be spun freely.

Adjusting the back brakes involves accessing the adjuster wheel inside the hub with a flat-bladed screwdriver, via a hole in the plate on the back

“The idea is to make gradual changes by rotating the spiked adjuster wheel with the screwdriver, until the brakes prevent the wheel from spinning freely. Once you reach this point, the adjuster can be backed-off just enough to allow the wheel to spin again, at which point the brakes will be properly adjusted. “I also find on tractors that I work on, that the brakes have often been wrongly reassembled following previous work, whether it be the fitting of new shoes or a complete overhaul. Those with insufficient experience or knowledge will typically reassemble the brakes with the shoe return spring wrongly connected. The result of this mistake is that the brake adjuster is allowed to work itself lose, which is far from ideal.”

Routine jobs

Other important aspects of routine maintenance which Ben highlighted – and where many new owners are often found wanting – include assorted electrical issues, grease points, antifreeze concentration, wheel nut tightness and battery condition.

“Typically, many old tractors suffer with poor electrical systems, and basic faults such as the lights not working are common, he told me. “Issues like this are usually caused by one of three things; a fault with the dynamo or the control box, or a bad earth. The latter is the easiest and cheapest to sort out, as all that’ll probably be necessary is to clean the contacts.

“Back in the day, dynamo issues were often sorted out by having the unit rebuilt, but things have moved on a lot in recent years, and it’s now cheaper and quicker to by a new, remanufactured dynamo from one of the many suppliers who now advertise in the specialist press, than it is to have a faulty unit reconditioned. The Super Dexta I’m working on at the moment had a dynamo issue and I could have certainly got the unit repaired for perhaps £70, but I ordered a brand new replacement (which arrived the next day) for just under £50.”

There are plenty of grease points on Ford and Fordson tractors from the classic era, and it’s important that these aren’t allowed to run dry. “You’ll need a decent grease gun to ensure all the nipples are properly treated,” Ben advised, and, depending on the model, you’ll typically find these on the wheel hubs, the back of the track rod ends, the pedals and on the linkage levelling box.

“A multi-purpose lithium grease will be fine; there’s no need to splash out on a high-tech alternative. Also, with regard to the grease gun and its ease of use around a tractor, my recommendation is to buy one with a flexible pipe, rather than the sort that have a rigid, metal delivery tube – much more versatile.”

Rookie error!

A rookie, maintenance-related error that both experienced and new tractor owners continue to make, relates to the use of antifreeze, as Ben explained. “For some reason, lots of owners seem to think that their tractor engines will be immune from the expansion effect caused by freezing water. Sadly, this isn’t the case, and I come across a regular trickle of tractors that are leaking water due to a cracked head, block or both.

“I think part of the problem is that lots of owners have stopped thinking about antifreeze because it’s not something they have to worry about with their modern road cars any more – service workshops take care of such things now. It just doesn’t figure in our motoring lives, so owners forget about the need for it in their tractors. But it can be a costly mistake to make.

It’s very important to keep the antifreeze concentration in a tractor’s coolant up to scratch. Too many owners forget all about it, with often disastrous results when the frosty weather arrives

“Elsewhere around the tractor,” Ben said, “I always advise owners to keep a regular eye on the tightness of the wheels nuts. This is another important aspect that’s all too easily forgotten. People tighten them once and then assume that they’ll hold when, sometimes, they don’t. They can loosen with use. It’s also important to avoid over-tightening wheel nuts, because older wheels can crack around the stud holes. To be sure about the correct tightening you’ll need to use a torque wrench.”

Lastly, Ben touched on battery condition monitoring. “Owners need to keep the tractor’s battery in mind, especially on tractors that aren’t used much. It’s simple and affordable nowadays to buy yourself a trickle charger (even one powered by a solar panel) that you can keep connected while the tractor’s sitting in the shed. Alternatively, if you know the engine won’t need to be started for a long period, or winter is approaching, then it makes sense to disconnect the battery altogether. The repeated re-charging of a battery after its become flat will shorten its service life significantly, so it pays to take care to avoid needless electrical discharge.”

A simple circuit tester is cheap to buy but a real asset when it comes to checking tired tractor electrics

Overall, then, the good news is that looking after the basic needs of your tractor isn’t going to cost you a fortune in parts, tools or time. If you’re sensible about your maintenance, adopt a regular, servicing routine and keep a common sense eye on overall condition, then there’s no reason why even a complete beginner can’t make a decent job of keeping their tractor running reliably, sweetly and safely.

To subscribe to Ford & Fordson Tractors, click here