A Scandinavian surprise

Posted by Chris Graham on 14th March 2020

Michel Meesters, from Denmark, claims to have one of just a handful of factory-produced IH Hydro 85s with a driven front axle. Scott Lambert explains more about a Scandinavian surprise

A Scandinavian surprise: Michel Meesters, from Denmark, purchased this International Hydro 85 after a deal to export it to Eastern Europe fell through. It started its life in Norway, and is purported to be a rare, factory-built four-wheel-drive version of the model. All photos: Michel Meesters (unless stated).

As anyone with a passion for – or knowledge of – International Harvester may know, of all the models built at Doncaster after the introduction of the World Wide Series in 1970, tractors with a hydrostatic transmission are seldom seen. Although IHGB produced hydrostatic versions of several World Wide models – most notably the 574 – it was the gear-drive counterparts that enjoyed the spoils, as they were true all-rounders.

Despite IH marketing its hydrostatic tractors in a way that portrayed them as being suited to all jobs on the farm, the reality was that they were best suited to power take-off work, or specialist applications. This meant that they carved out a niche on hedge-cutting duties, as the power source for conventional and round balers and for planting and/or precision row-crop work.

Constant engine speed

Their ability to maintain a constant engine speed for PTO-driven equipment, while providing the operator with the option of changing the ground speed at the push or pull of a dash-mounted lever, made them a great choice for the aforementioned jobs – but they had their foibles too.

International Harvester’s hydrostatic tractors excelled at PTO operations, although the PTO power was considerably less than the engine’s maximum output. The 540rpm shaft was rated at 56.7hp, while the 1,000rpm shaft produced 61.3hp. Maximum lift capacity at the lower link ends was 2,000kg (4,400lb).

The predominant problem with these tractors, aside from increased noise levels and additional heat from the transmission, was parasitic power loss – this method of propulsion used up more of the engine’s power than a gear-drive model, which meant that the 454, in particular, was not great in Hydro guise.

IHGB realised this and withdrew the 454 Hydro from its line-up in 1973, briefly replacing it with the 474 Hydro, but leaving the gear-drive model to continue on to 1977. This meant that the 574 Hydro was the company’s largest hydrostatic offering but, at 68hp, it wasn’t powerful enough to suit the most demanding applications. IH rectified this at a later date, likely to be June 1976, with the arrival of the ‘Q’ cab, when it gave the 574 Hydro a 674-spec engine.

With the launch of the Hi-Performers, otherwise known as the 84 Series, the hydrostatic offering was called the Hydro 84 (built in 1977-81). With 80hp generated from the D-246 four-cylinder engine, the new model was better suited to more demanding tasks than the first incarnation of the 574 Hydro, but it was still only offered in two-wheel-drive configuration.

Despite IH’s hydrostatic tractors having struck a chord with potato growers, where the infinitely-variable speed control was useful for planting and particularly harvesting, IHGB hadn’t offered the option of four-wheel-drive for pulling such equipment in arduous conditions.

Savvy conversions

Some savvy farmers and dealers converted World Wide Series models, Hi-Performers and even later tractors (see ‘Bullmer’s Hydro’) to become four-wheel-drive, hydrostatic tractors, but they were seldom seen – with the exception of one or two in the public eye.

The late Don Woodhouse used a converted IH 574 Hydro when competing in ploughing matches. (Photo: Andrew Brown)

The late Don Woodhouse, for example, used a 574 Hydro with a driven front axle to good effect in many high-profile ploughing matches, but it wasn’t until the introduction of the Fieldforce range (85 Series), that a four-wheel-drive IH with a hydrostatic transmission became a factory-built option for the European market.

The Hydro 85 – essentially a hydrostatic version of the 785L – replaced the Hydro 84 in 1982 and, before production ceased in 1984, a lowly number of approximately 250 had been built. Due to this fact, finding straight examples of the Hydro 85, referred to by IH as the H85, is becoming increasingly difficult. So, to be made aware of the rarest of them all – a factory four-wheel-drive example – is extremely exciting.

Michel Meesters, from Denmark, is the current owner of the tractor featured here, which was built in 1984. He told T&M: “I know that the tractor was sold from new in Norway by Lena Maskin AS. It was imported to Denmark and was meant to be sold on to Eastern Europe, but they didn’t want it because of the hydrostatic transmission. This presented me with a chance to buy it, which I duly did.

The serial number plate indicates that the tractor was built at Doncaster in 1984.

Information scarce

“I’ve owned the tractor for about a year now, and have asked a lot of people about it. I discovered that the brochure for IH products available in mainland Europe mentions the Hydro 85 with four-wheel-drive, as well as the American brochure. Besides this, I can’t find much about it. There are some that have been converted since, but I’m assured that this is a factory build.”

Michel went on to say: “It’s still on four Goodyear tyres, and there are no signs of wear on the linkage and very little on the pick-up hitch – that’s why the low hours seem possible. Plus, many small tractors in Norway are just used to clear roads of snow.”

Philip Ponton was training instructor at the Service School at the time of the 574 Hydro, before moving on to sales roles in the latter half of the 1980s. “In my early days with IHGB, I immediately became involved with the 74 Series Hydro tractors. Its infinitely-variable concept was totally unique to IH. Subsequently, the H84 and H85 models were released and, to my knowledge, all were only available in two-wheel-drive,” he explained.

“When I saw the pictures of the four-wheel-drive H85, my first thoughts were that it was a one-off conversion, albeit an extremely professional one. But is it practical? Bearing in mind that the Hydros excelled on PTO applications, such as vegetable harvesting, a four-wheel-drive would be of great benefit in adverse conditions.

“Also, the Hydro skids were bought by companies such as Brunette, which made a forestry forwarder with six, equal-sized wheels. By comparison, a four-wheel-drive Hydro tractor is a light-duty machine.”

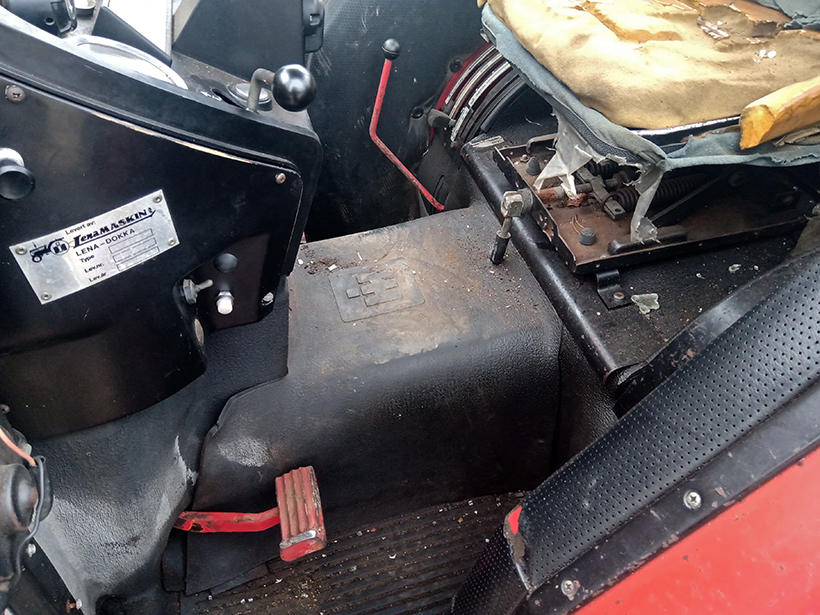

The interior reveals what you’d expect from a Hydro 85…

… including a simpler hydrostatic control lever arrangement than was fitted to the 574 Hydro.

Model exposure

Philip’s former IHGB colleague, Martin Monk, worked in the Product Training and Marketing departments, and was exposed to many different machines for global markets. He can’t recall ever seeing a factory-built four-wheel-drive Hydro, but acknowledges that if there was likely to be one sold anywhere, it would be Scandinavia.

“As Philip has hinted, forestry applications were popular outlets for IH’s four-wheel-drive tractors, and this would seem the most plausible explanation for a four-wheel-drive hydrostatic tractor, as the additional traction and stability would be beneficial in this type of environment,” Martin explained. “In all my years at IH, I never saw one, but this doesn’t mean that this tractor isn’t a factory build. There is the possibility, however, that it could have been converted in Norway.”

One person that appreciates how special IH’s hydrostatic tractors are is Suffolk farmer, Andrew Brown. His father’s older brother, John, was involved in the development work on such transmissions with Lucas in the 1960s, and Andrew’s father subsequently became interested in the technology, buying several Hydro 84 and Hydro 85 models for use on the family farm.

Other than the four-wheel drive engagement lever, which appears to be from an XL-cabbed model, the other controls are as you’d expect to find in a Hydro 85 fitted with an ‘L’ cab. Note the instructional decals in Norwegian.

Andrew maintains the farm’s fleet, and has vast experience when it comes to IH’s Hydro tractors. He explained: “The four-wheel-drive option was never officially offered in the UK, although a few may have been specially ordered and several have been created over the years using parts from gear-drive models. Back in the 1980s, no other tractor could offer infinitely-variable ground speeds while keeping a constant PTO speed, and so this made Hydros quite popular tractors for operating potato harvesters, and a few dealers converted some to four-wheel-drive.

1960’s approach

“The concept of utilising oil to transmit the power from an engine-driven pump, to drive a motor to propel a tractor, was seen as the future in the 1960s, with several manufacturers spending money on research. In the UK, both Lucas and Dowty were working on ways of incorporating pumps and motors into tractor drivelines. Dowty came up with its Taurodyne hydrostatic transmission, and even licensed the design to Eaton in the USA, as far back as 1964.

“Different manufacturers approached the concept in different ways, but most shared the principal of using a variable-displacement axial piston pump to drive an axial piston motor,” Andrew explained. “Reduce the displacement of the pump and the slower the motor will turn. Add in a variable-displacement axial piston motor, and more torque can be transmitted by increasing the motor capacity at low speed.

“In the end, International Harvester was the only mainstream manufacturer to commit to volume production, and launched the US-built 656 in 1967. More models soon followed in the US and, when IHGB launched the all-new, Doncaster-built World Wide Series 50 years ago, both the 454 and 574 had the option of a hydrostatic transmission.

“In theory, the concept of being able to vary speed and direction without a clutch, while maintaining constant revolutions, is brilliant. But utilising oil as the way of transmitting the power has its limitations and disadvantages – the most evident of which was efficiency. IH placed the pump and motor next to each other in the main frame casting, eliminating the use of any hoses or pipes to transfer what had the potential to be extremely high-pressure oil between the them.”

Michel has replaced the windscreen since he purchased the tractor, but he is yet to fit an original-type exhaust silencer.

Creative marketing

Andrew continued: “However, the pump, motor and live drive gears all needed to be completely submerged in oil, and this caused both drag and heat to build up in the transmission oil. Excessive amounts of heat were also created when the tractors were used for heavy draft work. IH fitted a larger transmission oil cooler and a multi-bladed fan to draw more air through the grille to help keep things cool but, again, this consumed more power than a gear-drive equivalent.

“Add to this the fact that the tractors were advertised with a 17-gallon fuel tank, but they would start spluttering after about 11 gallons had been burned, so in an age when few people actually measured the quantity of fuel used accurately, the hydrostatic transmission got a bad name for fuel consumption.”

Commenting on hydrostatic tractors’ ability to perform all of the tasks asked of them, Andrew said: “IH marketing had a difficult task, as the Hydro was really a specialist tractor and, throughout history, niche machines have never sold well. A tractor has to be universal, so it was often shown in publicity material operating completely unsuitable equipment because, in the marketing department’s mind, this demonstrated the tractor could do any job a gear-drive could.

“In practice, customers could buy one for the wrong reasons. Why would you need infinitely-variable speed at constant engine revolutions to commercially pull a plough? But IH marketed the tractors for this, even stating that costs could be reduced and productivity increased.”

Understanding the concept

Back to the four-wheel-drive H85 and, once again, Andrew’s knowledge explains the concept well. “US models of International’s Hydros were offered with front-wheel assist (four-wheel-drive), but the tractors were converted by outside, approved suppliers,” he said. “Ellwood and Colman were companies that IH worked with, much like in the UK where IHGB worked with Roadless and County.

“Towards the tail end of the production of the gear-drive 475, 574 and 674 models, a KIMCO four-wheel-drive option was available, and a small number of these found homes on farms. This conversion, in an improved form, continued to be available on the later, 84 Series models, except the Hydro 84.

“Finally, with the launch of the 85 Series range in 1981, a true factory-built four-wheel-drive option became available – with durable components, including a side-driven ZF axle. At this point, IH decided to offer the Hydro 85 with the four-wheel-drive option, but not for the UK market – just for export to Europe, Middle East and Asian markets. Sales brochures show the option alongside its gear-drive cohorts in the specifications. The North American market could also order four-wheel-drive hydrostatic tractors, but they were still marketed as the 84 Series.”

The 85 Series brochure for the Europe, Middle East and Asian markets.

So, if IH’s hydrostatic tractors were popular with those that operated them, why were four-wheel-drive options not offered in the UK? Andrew Brown believes he has the answer. “The reason this option wasn’t commonly available is that it’s not to provide more, out-and-out traction, as the hydrostatic unit won’t have the lasting power for that,” he said. “It’s for very specialist jobs. Loader work and hedge-cutting are classic examples of tasks a four-wheel-drive Hydro would excel at in greasy conditions, as being able to control speed and direction without a clutch is what Hydros are all about.”

Correct ratio?

There’s also the question of gear ratios, and making a hydrostatic tractor suitable for use with a driven front axle. Once more, Andrew explains: “Over the years, Doncaster Hydro production changed slightly. The first 574 models had the highest-speed crown wheel and pinion set available. This had a tooth count of 14:51, giving a ratio of 3.64:1. These were quite famous back in the early ’70s for being swift; on 11×36 tyres, they would reach 23.8mph.

“The later 84 Series and 85 Series were fitted with a slower ratio, as it had been possible to stall the 574’s transmission in low range with the 3.64:1 ratio. The ratio of crown wheel and pinion is always shown on the skid unit’s ID tag and, before the 85 Series, this tag was on the bell housing, above the starter motor. But it was moved to the rear with the 85 Series, and is found on the right-hand side, near the PTO.

The build of a four-wheel-drive Hydro would have to be altered to suit the addition of the front axle. Andrew said: “A normal H85 would have a build code of BRYD, where B = Fast speed, R = 12:53 teeth and ratio 4.41:1, Y = 611rpm PTO and D = Dual-speed PTO. Two-wheel-drive Hydros are also fitted as standard with 11×36 wheels.

“Michel’s tractor’s skid unit tag is stamped BTYD, where T = 11:52 teeth and ratio 4.72:1. Four-wheel-drive tractors are almost always set up to have some ‘lead’ in the drive to the front wheels, meaning they are turning just slightly faster than the rears, to enable the axle to pull the tractor, rather than be pushed by the rear. The optimal amount of lead is between zero and 3% and, to achieve this, the design engineers choose the best diameter of front and rear tyres matched to the gearing, ending up with what’s called an ‘inter-axle ratio’.

ZF front axle

“IH 85 Series four-wheel-drive tractors are fitted with a ZF APL-1351 front axle, with an inter-axle ratio of 1.4039. This lead could not be achieved with a standard-build, two-wheel-drive Hydro, without changing the rear crown wheel and pinion to the 4.72:1 ratio. Michel’s tractor was built this way, along with it having the optional 12×38 tyres required to achieve this.”

This tag indicates that the tractor is with a fast transmission (B), with 11:52 teeth and ratio 4.72:1 (T), 611rpm PTO (Y) and dual-speed PTO (D).

To further assess the tractor’s ‘credibility’, we asked Andrew to comment on the tractor’s controls and interior. He noted that the four-wheel-drive engagement lever has a brown knob, like an XL model but, otherwise, everything appears to be as it should. “With any IH Hydro model, it’s always interesting to divide the mileage by the number of hours clocked up,” he said. “This gives an idea about what sort of work the tractor’s done or, in some cases, if the figures match. The hours and mileage are both very low, giving a plausible 2.5mph average speed. This average doesn’t allow for reversing and stationary work, so the actual speed the tractor has been used at when moving will be higher.”

The tractor features a side-driven ZF APL-1351 front axle.

Assessing a tractor’s provenance isn’t always easy and, whether Michel’s four-wheel-drive Hydro 85 is a factory-built example or not, is difficult to confirm. But the evidence seems to suggest that it is.

If you can shed any light on the subject, or own a four-wheel-drive IH hydrostatic tractor, please get in touch as we’d love to hear from you via email; to: tm.ed@kelsey.co.uk

Bullmer’s Hydro

International Harvester’s hydrostatic tractors remained popular with users long after production ceased, leading some individuals and dealers to create their own using spare parts. Robert Buchanan produced what’s thought to be a one-off, four-wheel-drive Case IH ‘895 Hydro’, while working as a service engineer at Ross Farm Machinery Ltd, in the 1990s.

This Case IH 895 Stockman was fitted with a reconditioned hydrostatic transmission from an earlier tractor by Ross Farm Machinery Ltd in 1993. (Photo: Robert Buchanan)

He told T&M: “Russell Brett, of Ross Farm Machinery, was contacted in 1993 by HP Bulmer Ltd, as the company was looking to replace one of its fleet of ageing IH hydrostatic tractors. It operated a mix of 74, 84 and 85 Series, two-wheel-drive machines supplied by the local dealer, Farmore Farmers, and later West Midland Farmers. The first was supplied during the mid-1970s.

“Bulmer’s need was for an 80hp tractor with four-wheel-drive, a hydrostatic transmission and air conditioning. It was agreed that a donor hydrostatic unit would be supplied for reconditioning, before being fitted into a new Case IH 895L four-wheel-drive tractor, which would be ready for the apple harvest in September, 1993.

“Work started in early spring, 1993, with the donor unit being stripped down, inspected and reconditioned under the guidance of RFM’s service manager, Francis Evans. It was then fitted into a new 895 ‘Stockman’. The build went smoothly, with any glitches being sorted as things progressed, and a new 85 Series cab roof was sourced, which allowed us to fit a roof-mounted AC unit from Kysor, through the roof hatch space. All pipework and lighting was relocated in or under the cab, as apple tree branches can be very abrasive and destructive!

This interior shot shows the hydrostatic control lever on the left-hand side of the dash panel. (Photo: Robert Buchanan)

“By July, 1993, the Case IH ‘H95’ four-wheel-drive tractor was complete and, after being thoroughly tested in the workshop, it was delivered to HP Bulmer Ltd. at Woodhouse Farm, Martley, Worcestershire, for a final test – before having an apple-shaker fitted for the upcoming harvest.

“I was pleasantly surprised to learn recently that, some 27 years later, this unique tractor that I’d built and tested, was still earning its keep, albeit no longer for HP Bulmer Ltd.”

It’s now owned by Robert Laybourn, who lives near Pontefract, and has a prolific collection of IH and Case IH tractors. He purchased the ‘H95’ about eight years ago.

The tractor as it is today. (Photo: Robert Laybourn)

You can subscribe to Tractor & Machinery magazine by clicking here