International Harvester’s cultivators

Posted by Chris Graham on 11th August 2021

With autumn just around the corner, Scott Lambert takes a look at some of International Harvester’s cultivators and chisel ploughs.

International Harvester’s cultivators: An International B-275 pulling a B-930 toolbar equipped with nine rigid tines. (All photos courtesy of IH promotional literature)

Massey Ferguson was renowned for its full line of equipment throughout the 1960s and ’70s, but the other main tractor manufacturers also had equipment that complemented their prime movers.

Like MF, some of this was ‘badge-engineered’, while other items came from overseas factories to fill gaps in the product line. International Harvester was once such company, using the likes of Huard ploughs and Pettit trailers and disc harrows in its own livery, to offer an entire range of IH machinery. Combines and hay conditioners came from IH France while mowers and manure spreaders were supplied by IH Sweden.

Among the implements that IHGB offered throughout the decades was a range of cultivators and chisel ploughs to suit various applications – some of the most popular of which are shown here.

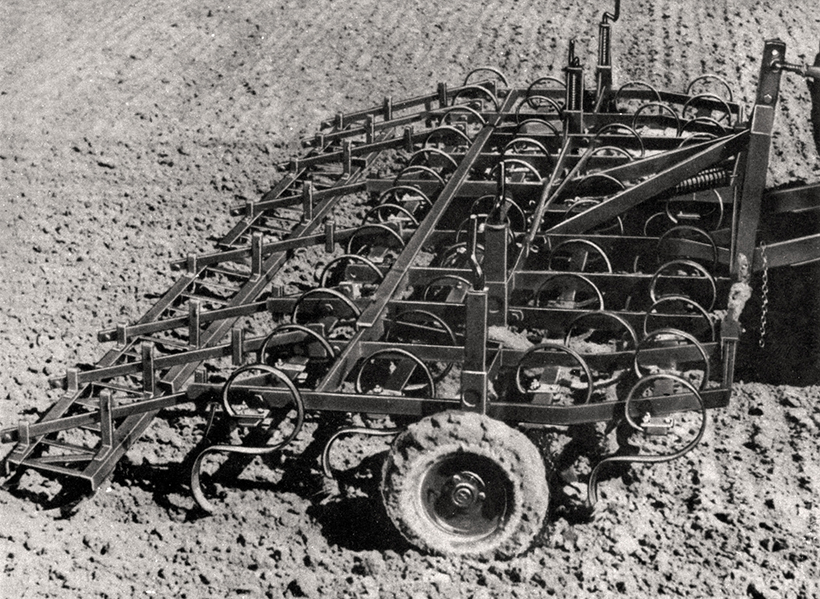

The first such machine was not solely a cultivator, as it was four implements in one. The B-930 was a mounted toolbar for category I tractors that could be equipped with nine spring-loaded tines, nine rigid tines, nine spring tines or three ridging bodies.

The frame comprised steel channels with four, tubular-steel braces, with the headstock made of flat steel. Eight feet (2.5m) wide, with the front and rear channels at 20in (510mm) centres, the bare frame of the B-930 weighed in at 145lb (66kg). Holes drilled one inch (25mm) apart across the entire width of the main frame allowed for accurate positioning of tines or bodies, without affecting any depth wheels that may be fitted – which didn’t use the same attachment points as the tines etc.

The spring-loaded tines were designed to tackle the toughest jobs at normal working speeds, with two strong springs enabling the tine to tilt rearwards should it encounter an obstruction.

Rigid tines could be set in two rows, like their spring-loaded counterparts, with a shear pin protecting the frame from damage should a hidden obstruction be met. They were suitable for general cultivations and row-crop work.

Spring tines were designed to withstand the shock of hitting hidden obstructions and, thanks to the hardened spring steel used in their manufacture, had a pulverising effect on the soil – helping to create a fine tilth.

In 1966, the B-930 cost £21-5-0, while the three tine configurations would have set you back £58-19-0, £22-18-0 and £18-12-0, respectively.

2-11, 2-12 & 2-13

Next on our whistle-stop tour of IH’s cultivators is a spring-tine trio that could be specified with four types of share. The most basic of these was the 2-11 with a rigid headstock and no depth wheels – only suitable for tractors with full draft control. Five variations were available.

The 2-11, 2-12 and 2-13 were spring-tine cultivators with reversible, goose foot, grass or row-crop tines. Working widths of 5ft 1in to 17ft 5in could be achieved, depending on the model, while a Hop version of the 2-12, with a working width of 4ft 5in, was also available.

The second and third models, the 2-12 and 2-13, utilised an automatic depth stabiliser and pneumatic wheels, although the 2-12 could also be specified with steel wheels. Six sizes of the 2-12 could be specified, as well as a Hop model, and the 2-13 came in four sizes – utilising a reinforced frame with folding side extensions and either two or four pneumatic wheels.

A welded steel frame was used to mount the tines, with four types of hardened and tempered steel allowing shares to choose from – a 1.38in (35mm) reversible, 2.75in (70mm) goose foot, 0.63in (16mm) grass and 4.13in (105mm) row-crop.

Optional extras included a front-mounted levelling board for ploughed or rough land, and side extensions for four tines – useful in orchard and row-crop applications and to make the cultivator suitable for larger tractors.

Working speed was 5-7mph (8-11kph) and 1-2dbhp was required per tine, depending on the soil type.

The 1-1

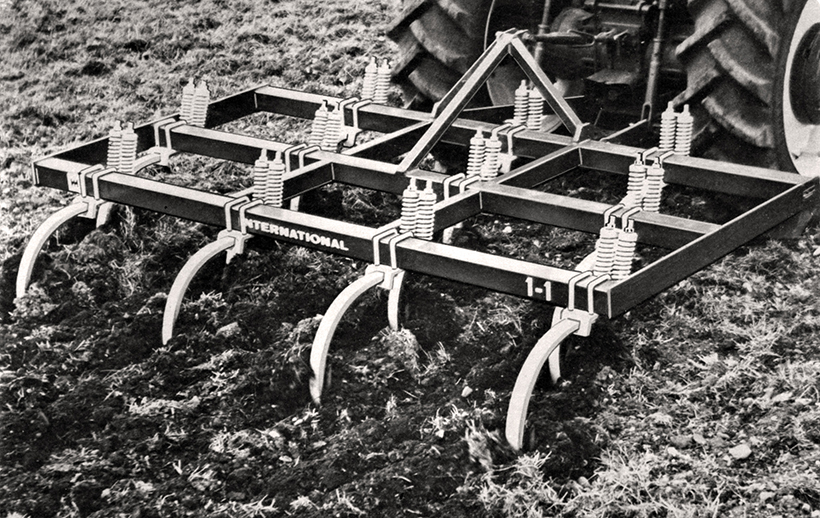

Our penultimate model is the IH 1-1 chisel plough – comprising a massive steel frame with main beams made from 4x4in (102x102mm) hollow section. The frame alone weighed in at 485lb (182kg).

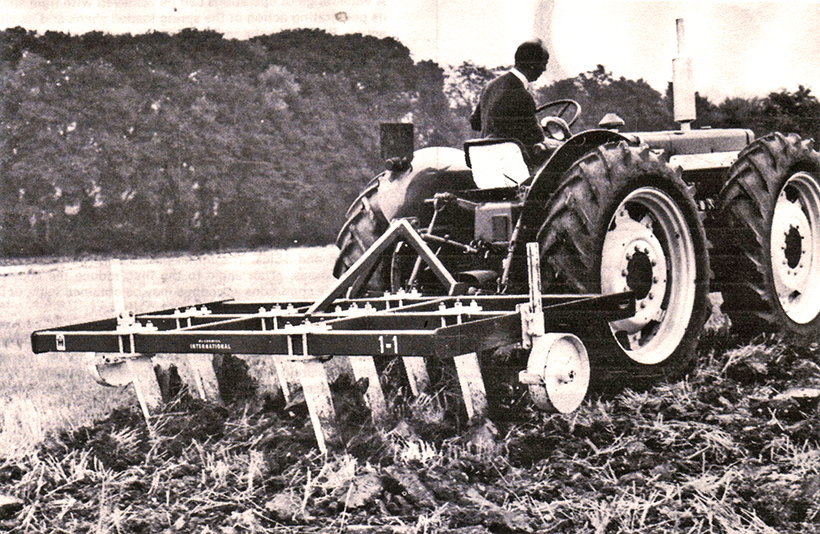

The International 1-1 was a chisel plough that could be ordered in three sizes, with either five, seven, nine or 11 shanks. Straight rigid, curved rigid or cushion shanks were fitted to suit the application. Straight rigid shanks are seen on this seven-shank model, pulled by a 634 All Wheel Drive.

Three widths were available, from 6ft 6in (2m) to 10ft (3m) and three shank types could be specified – straight rigid, curved rigid or cushion shanks – with a 2in (50mm) wide reversible chisel point as standard. Options included twisted left- or right-hand shovel points, a 4½in (115mm) reversible shovel and an 8in (200mm) triangular shovel.

The straight, rigid shanks were angled to create less draft and better trash clearance, and were ideal for pan-breaking or mulching stubble, to a depth of 15in (380mm).

Cushion shanks could be specified for those looking for a vibrating action for seedbed preparation. This was achieved through the use of two tension springs on the mounting clamp.

An 11-shank IH 1-1 equipped with cushion shanks. Working width was 9ft 4½in (2,856mm). Power requirement was 35-45hp, 40-55hp, 50-65hp and 60-90hp for the five-, seven-, nine- and 11-shank models, respectively.

Curved, rigid shanks were designed to work in the range between the two other shanks, with sufficient ‘flex’ to overcome obstacles and resist damage.

The 45

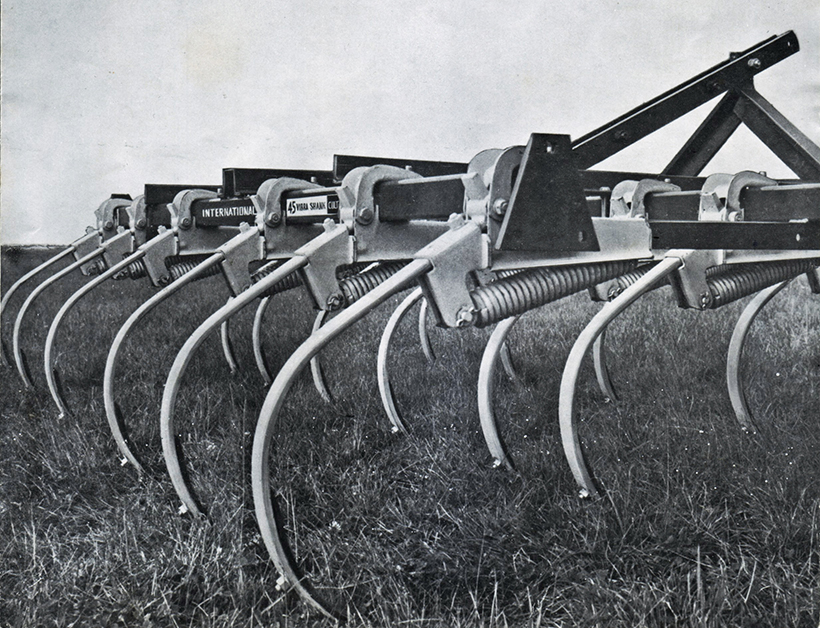

Finally, the 45 ‘Vibra Shank’ cultivator. This type of design is still used extensively in the USA, but first appeared in Europe around the start of the 1970s.

The key to its success was its shattering action – with each shank mounted to a clamp containing a tension spring. This was said to provide a greater vibration than a conventional spring tine, helping to break up clods for seedbed preparation.

The International 45 Vibra Shank came in four sizes, and was fitted with reversible points. It had an excellent shattering effect for creating seedbeds, and came in working widths of 8ft 6in, 12ft 6in, 15ft 6in and 18ft 6in, with 17, 25, 31 and 37 shanks, respectively.

Clearance between the front and middle and middle and rear frames was 29in (737mm) and 25in (635mm) respectively, with an underframe clearance of 20½in (521mm). If a large obstacle was encountered, each shank had the ability to break back by 10½in (270mm).

The number of shanks could be reduced and the spacing increased to make the 45 better suited to heavier cultivation tasks, up to a depth of 6in (150mm).

The shanks had the ability to break back by 10½in (270mm) if a large obstacle was encountered.

Optional extras included steel depth wheels and twisted points – turning soil and roots to the top to speed up drying and decomposition.

As the 1970s drew to a close, International Harvester’s range of implements was dwindling, as the specialists in tillage machinery began to dominate the market. IH’s days as a ‘full liner’ were almost numbered.

For a money-saving subscription to Tractor & Machinery magazine, simply click here

Useful contacts

Agricast

East Torrington, Lincolnshire

Tel: 01673 857619

agricast.net

Agri-Linc Ltd

Edenham, Lincolnshire

Tel: 01778 591225

agri-linc.com

Kramp UK Ltd

Biggleswade, Bedfordshire

Tel: 01767 602615

kramp.com

Pan Anglia Ltd

Sudbury, Suffolk

Tel: 01787 242740

pananglia.com

Shoup Manufacturing Co. Inc.

Kankakee, Illinois

Tel: 001 800 627 6137

shoupparts.com

Sparex Ltd

Exeter, Devon

Tel: 01392 368892

gb.sparex.com