Lifelong traction engine enthusiasts!

Posted by Chris Graham on 10th January 2022

Sally Clifford meets lifelong traction engine enthusiasts Alan and Frank Jackson, and their current pair of superb engines.

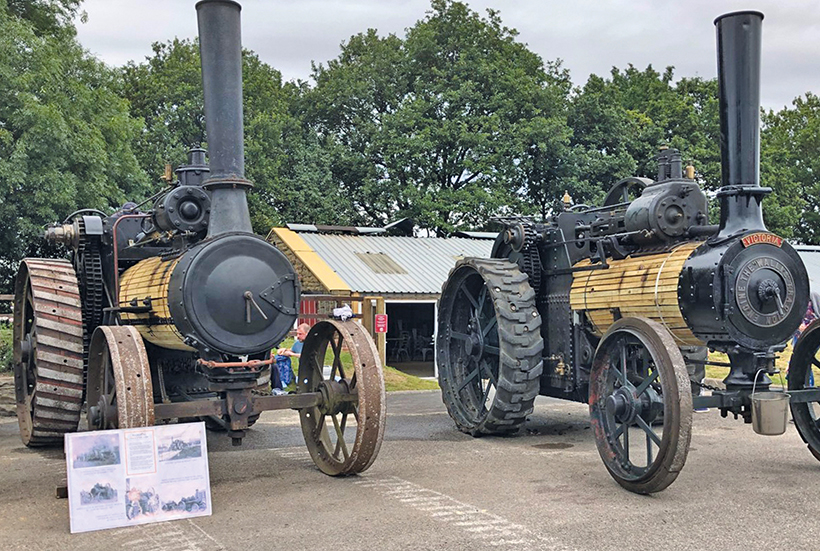

Lifelong traction engine enthusiasts: Frank and Alan Jackson with the Marshall and Wallis engines acquired by their late father, Fred. (Pic: Sally Clifford)

Their passion stems from their father, Fred Jackson, who had a keen interest and was an early preservationist. Alan has a photograph of himself, aged two or three, posing against the front wheel of one of Beeby’s single-cylinder ploughing engines at the 1955 Rempstone Rally.

The Jackson family have owned four engines over the years, but Alan and Frank have undertaken restoration work on the two they currently own, Wallis & Steevens No. 2489 of 1900 and Marshall No. 17328 of 1889.

Renovated, but still needing paint, the Marshall engine has undergone a restoration programme. (Pic: Sally Clifford)

The Marshall was found by Fred and three friends who clubbed together to purchase it in 1961, because he could not afford the £60 purchase price! “It was in a very poor condition and, as a small boy, I could remember standing at the back of it and seeing daylight out of the front,” recalls Alan.

Interestingly, Alan says Fred could remember the Marshall threshing on the family farm during WW2, and his grandfather recalled carrying water for it when threshing for his father when he was a boy back in the 1890s.

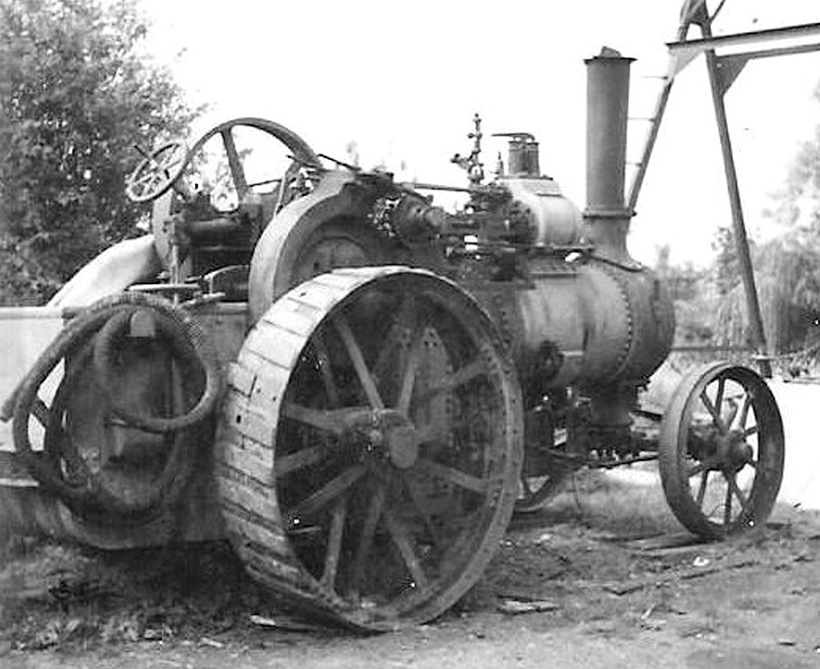

The Wallis engine as it looked before the restoration began. (Pic: Alan Jackson)

Much work was completed back in the early 60s, including some boiler work and the replacement of the smokebox, but after the family farm was sold, a new home for the old Marshall had to be found and it was stored in an old sand quarry near Tickhill.

Little work was carried out for the next 15-20 years. The engine had to be moved from the sand quarry during the 1970s to the Jackson’s yard. A little further work was done before the engine stood with little happening until the early part of the 2000s.

The Marshall and Wallis stand side by side; icons of a bygone age now serving a new purpose entertaining visitors at traction engine rallies in retirement. (Pic: Sally Clifford)

By then Fred had become old and was unable to carry on with the restoration, but his sons were determined to carry on with the work so Fred could see it up and running.

“We thought we would get it running so he could see it run while he could. It was repaired far enough to run at low pressure, and it chugged around the yard a bit, though unfortunately Fred could not manage to get on the footplate to drive it,” they explained.

Wallis & Steevens No. 2489 when delivered as part of the exchange. (Pic: Alan Jackson)

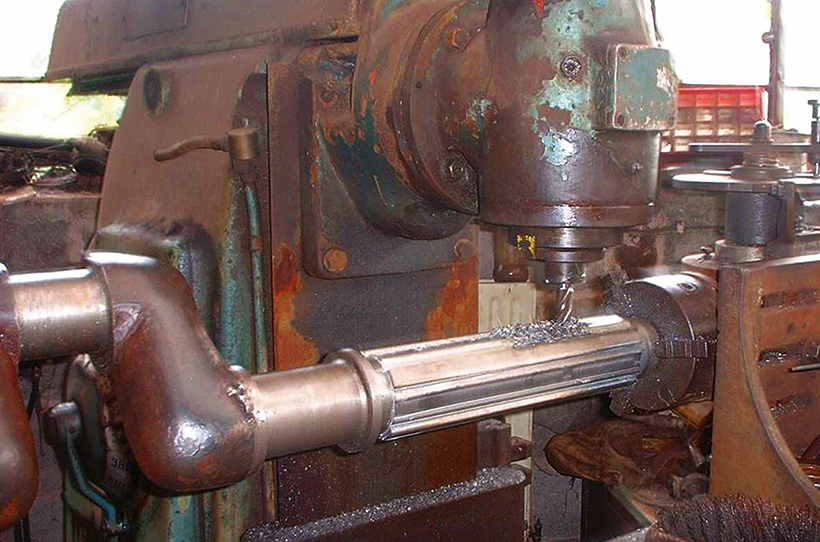

Since then, the boiler has been extensively repaired. Works include making a new crankshaft low gear; and new bearings to the crank and second shaft have also been made and line bored and other mechanical work has been carried out, but according to Alan there is still plenty to do. Preserving engines is a commitment, physically, financially and in time, as anyone involved will know.

According to the brothers, the engine left Marshall’s Gainsborough works in 1889 bearing the works number 17328. She was built to the order of George Law, the proprietor of Balby Brickworks. He apparently also ordered another engine from Marshall some years earlier that was delivered to somewhere in Derbyshire.

The crankshaft being rebuilt on the milling machine. (Pic: Alan Jackson)

Her early history is uncertain. The engine build sheet states the purchaser’s specific design requirements including an enlarged tender; no front draw bar; no brass boiler bands and an owner’s and lessor’s plate was to be fitted which is consistent with use for road work hauling bricks.

However, she was subsequently owned by George Law’s cousin, Mr Sam Law of Misson, a threshing contractor. The ‘owner’s and lessor’s plate’ may indicate the engine was purchased new for Sam Law and to be paid on a hire purchase agreement, or it may have been used for hauling bricks: “Will we ever know?” the brothers ask.

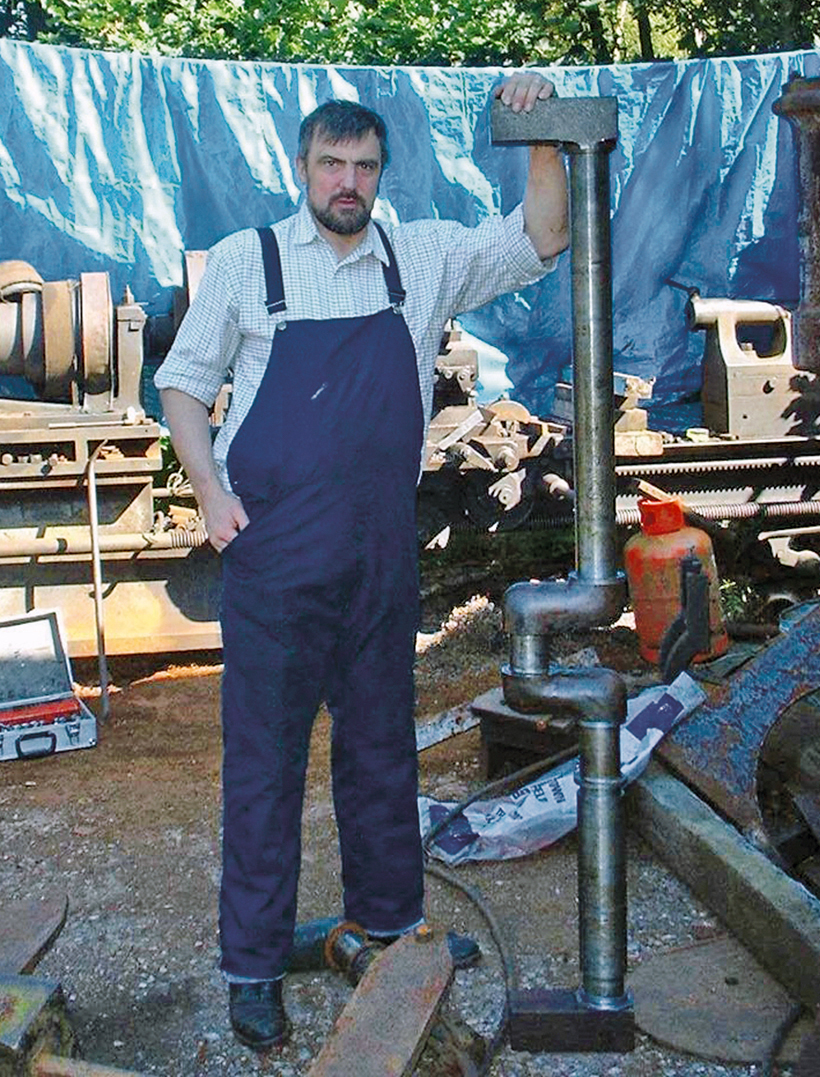

The lathe in the background was borrowed to do the basic turning, driven by a single-cylinder diesel engine and a flat belt. (Pic: Alan Jackson)

When it comes to the finer detail, the Marshall is an 8nhp single-cylinder, three shaft, two-speed general purpose engine and believed to be one of only two of this type remaining in the UK.

The 1920s marked another chapter in her working life when she was sold to threshing contractors Haldenby’s of Wroot, and driven by the late Jack Oldfield. “Jack was known to my father and supplied the working-day photographs,” says Alan. According to Jack, the Marshall had a new firebox fitted during the 1930s by Heptenstalls of Gainsborough. The work was apparently carried out on site in the farmyard and the cost was said to have been £20. The cylinder was re-bored and a new piston fitted at the same time.

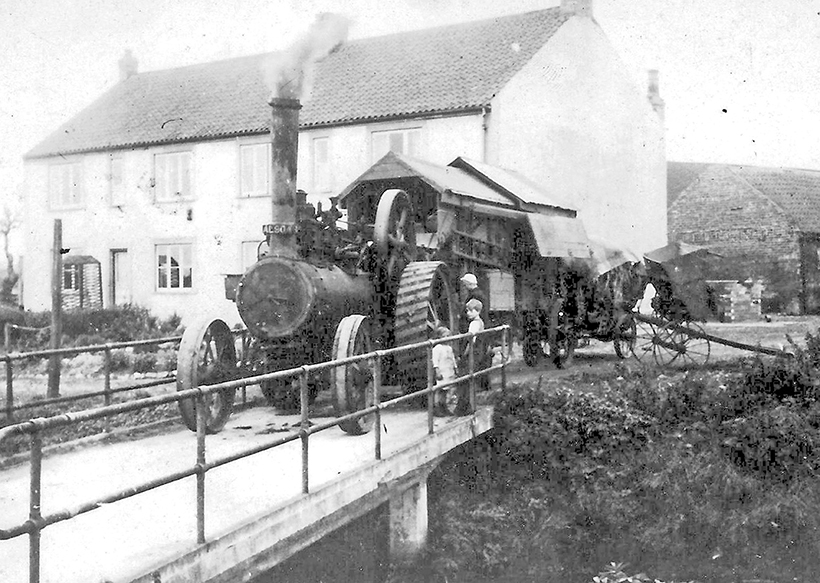

Marshall No. 17328 pictured around 1900. (Pic: Alan Jackson)

“We also believe that a new low gear crankshaft pinion was obtained and fitted about that time as that fitted to the engine when it came into our possession that had six splines and the shaft and high gear only three, and there was about 3/8” clearance on all splines, internal and external, and quite a lot of diametric clearance as well,” explain the brothers.

By 1949 the Marshall had been working for 60 years, but steam for threshing becoming uneconomic, and the engine was retired. She was sold to a Mr Brown of Epworth. It is understood he wanted her for steaming potatoes for pig food, but apparently she was never used for that role.

The Marshall spent all of its working life around farms in the Isle of Axholme area, and until it moved to its present location a few months ago, probably never moved more than a day’s drive from Gainsborough.

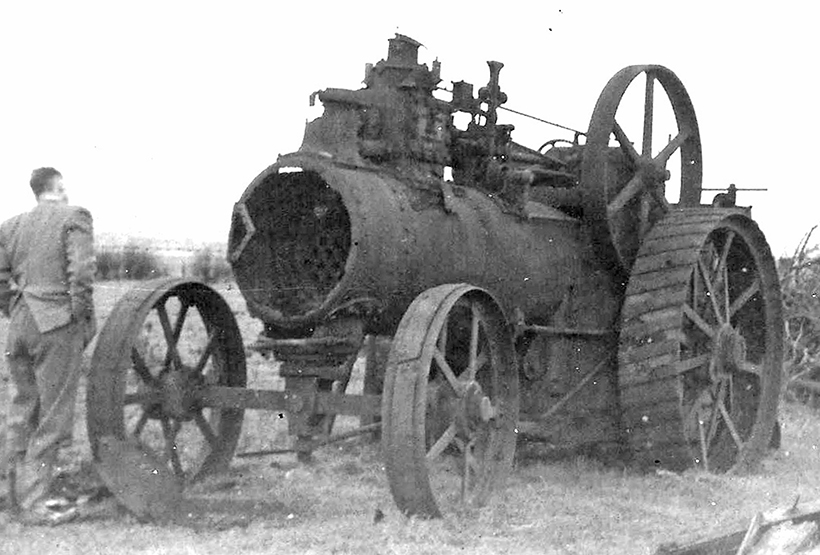

The Marshall pictured in Brown’s yard. (Pic: Alan Jackson)

In 1973 the Jackson’s acquired their second engine – Wallis No. 2489 bearing the nameplate Victoria. Built by Basingstoke-based traction engine, road roller and agricultural equipment producers Wallis & Steevens, No. 2489 was sold new to Ernest A Loveridge of Shiphay Farm, Colyton, Devon. She left the works on July 12 1900, and remained in Devon when her ownership changed to H Parnell of Musbury around 1920. Her next move was to Gloucestershire where, due to new legislation, she was awarded her current national registration number in 1920. Between 1920-27 the engine was with R&LC Lane of Stanway, Winchcombe, Gloucestershire.

The next owners were Collins Brothers of Inkberrow, Worcestershire, steam threshing and ploughing contractors, where she finished her working life in 1935, completely worn out. She was parked up in their yard in the open until the late ’60s when bought by a Mr Rockliffe of Stillingfleet for restoration.

The Jacksons acquired it as part of a three-way exchange involving their Garrett 4CD tractor, that was organised by the late Jack Hardy.

The Marshall leaving a farm during World War 2. (Pic: Alan Jackson)

According to the brothers, it was totally dismantled and the boiler was on its side in a farm yard. As part of the deal, the engine was assembled and the boiler repaired, with a boiler certificate, and was driven into the Jackson’s yard under its own steam, but still in poor condition. The flywheel-side bearing of the crank had worn completely through and it was running on the cast iron bearing housing. Everything on the engine was in similar condition.

About three years’ work was needed to get it back into reasonable running condition, including bearing repairs, re-straking and new front tyres. Since then work has continued, including making a new crankshaft, replacing bearing brasses, a re-bore and new piston and rings. The brothers explain that almost all of the work, except boiler repairs, has been carried out in the home workshop.

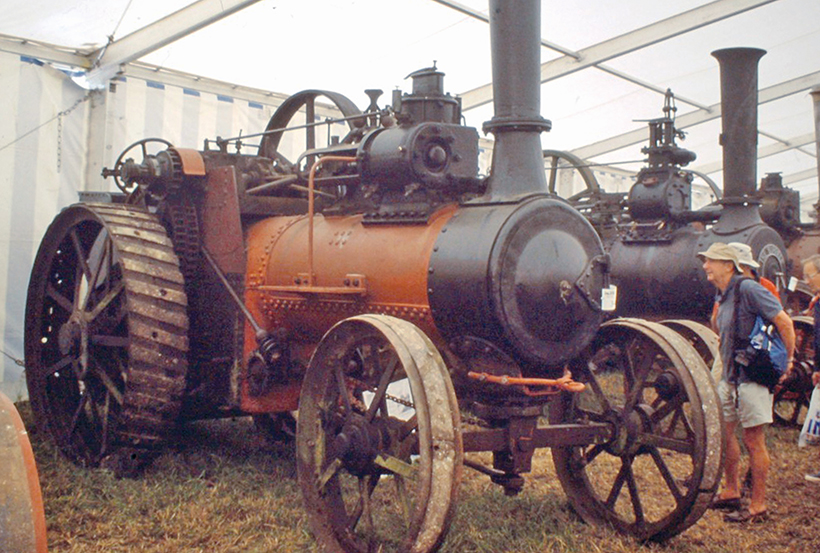

Seen at the Great Dorset Steam Fair in 2004 is Marshall No. 17328 as some well-known Australian fans look on. (Pic: Bob Moorman)

According to the brothers, the Wallis is now in reasonably good mechanical order, though they say the decorative finish leaves a lot to be desired!

Driving the engines is their greatest pleasure, and showcasing them to the public. However, due to them rarely travelling on a low-loader, it limits the number of shows they can attend, so it was a real privilege to spot them at a local steam event I attended.

For a money-saving subscription to Old Glory magazine, simply click here