Matbro Mastiff Minor

Posted by Chris Graham on 25th September 2020

Jurrie Potze, from The Netherlands, recently finished a long and involved renovation project on his unusual, Fordson-based Matbro Mastiff Minor. This is his story.

Jurrie Potze’s 1968 Matbro Mastiff Minor loading shovel, now in perfect working order.

I’m sure that many of you reading this will be familiar with the articulated 4WD tractor, the Matbro Mastiff 6/100MT. It was based on Fordson Super Major components, and was a spin-off from the Matbro Mastiff loading shovel. As I’m a technician, I’m very interested in the many Fordson Major conversions that were created down the years, which is why, back in 1997, I bought the wreck of a Matbro Mastiff Minor loading shovel. The principle of the machine is the same as that of the 6/100MT tractor.

The example I bought was in a very poor state; all of the pivot points were totaly worn out. The original gearbox had been replaced with a manual unit from a Fordson Major, and there was no tinwork left at all.

The first thing I did was to get in touch with Matbro, in England, and my letter to it was forwarded to Bill Clarke of AC Spares, based in Horley, Surrey. Mr Clark was one of the few remaining members of the original Matbro Company, having started work there in 1963. Now he’s a dealer in spare parts for the older machines.

The Matbro Mastiff Minor in as-bought condition, back in 1997.

He was able to supply me with some of the parts I needed, and was kind enough to send me copies of the original drawings for the tinwork. Then, however, I had to stop my work on the project for family reasons, and wasn’t able to get things moving again until 2012.

I thought readers might be interested in a summary of the restoration work done, so here goes.

Axles

Both front and rear axle are standard Super Major components, without brakes and linkages. But, in the front axle, the crownwheel is placed on the other side of the pinion, so that the wheels turn in the opposite direction. These parts only needed cleaning and the fitting of new seals.

Transfer box

This box contains a five-fold chain to transfer the power from the gearbox (above the axles) to the axles but, in my case, this was broken. So, a new one was sourced, together with new bearings and seals. Also, the aluminium housing was cracked in two places, which I welded and flattend with my Bridgeport milling machine.

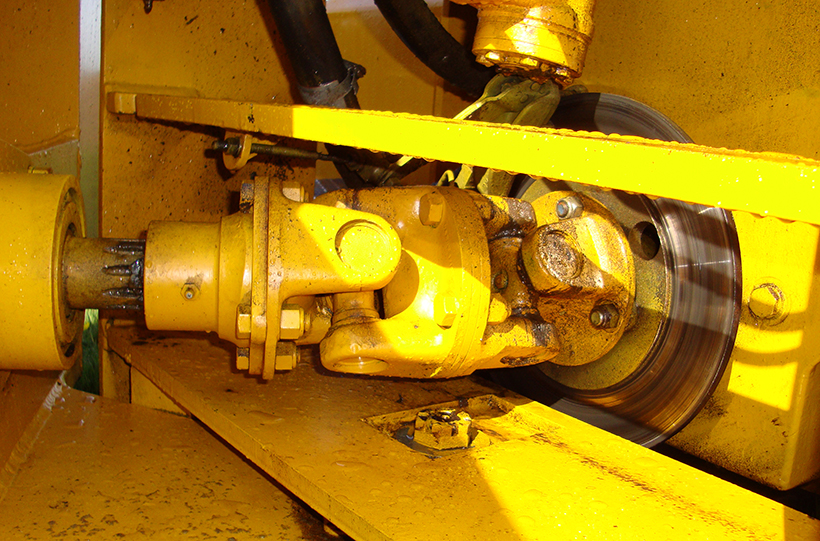

This single disc – on the transfer box output shaft – provides all the braking the vehicle has.

Gearbox

The gearbox is a Brockhouse automatic unit with torque converter, as mounted in many other Fordson Major conversions. But my Matbro had been fitted with a manual gearbox, presumably due to the failure of the original, which has a reputation for being rather weak.

I was lucky to find a replacement Brockhouse gearbox and torque converter in a scrap yard, although it needed a number of new parts, the trickiest of which to deal with were the planetary gears. I first contacted BT Transmission Services in Wednesbury, but they couldn’t help.

Fortunately, I then came across a Dutch company called Werklust, which had rebuilt a loader based on the Fordson Major, and still had some Fordson and Brockhouse parts in stock, which I bought. This enabled me to rebuild the unit back into usable condition.

A replacement Brockhouse automatic gearbox/torque converter unit was sourced from a scrap yard and rebuilt.

However, the sump didn’t fit the Matbro; it was too high. It seems that Brockhouse used several different sump designs, depending on the vehicle application. So I had to fabricate a replacement myself.

Engine

The motor of this Matbro is an industrial version of the Fordson Super Major’s powerplant – the Ford 592 E. So I found one from a Clayson M80 combine, and gave that a complete overhaul so that, now, it’s as good as new.

Chassis, main arm, bucket

All of the pivot points associated with these parts needed over-hauling. One small sentence, but a lot of work! I used a boring head to make the holes round again, then pressed bushes in to recreate the correct, original diameter. The cylinders were fitted with new piston rods and seals, and all of the hydraulic hoses and piping were renewed.

Brakes

The Matbro shovel only has one brake, which acts on the output shaft from the transfer box; a system which allows the operator to continue steering once the brake has been applied.

Of course, the condition of the brake was poor, and I had to replace the seals and pads, and fit a new disc.

Because the brake caliper is a Dunlop unit that, coincidentally, was also used on the MGA, parts were easy to source and reasonably priced. The disc, however, had to be made to special order, in a machine shop.

Tinwork

Because all the tinwork was missing, I had to fabricate everything myself, with the help of the technical drawings supplied by Mr Clark, in England.

Only 75-100 Mastiff Minors were built by Horley-based Matbro. This is one of the lucky survivors.

For the bonnet, Matbro used metal for the older machines, but switched to GRP for the later units. I chose to make the replacement bonnet using 2mm sheet metal as I found this easier to handle and work with.

Electrics

Most of the electical parts are from the Ford Motor Company so, with the help of the operator’s handbook, it was no problem to get the electrical system up and running.

MASTIFF MINOR HISTORY

There were only 75-100 Mastiff Minors built; many operators found them too small for their needs. My machine, with serial number 3599, was built in 1968, and was first delivered to construction plant specialist, R Ruthemeyer, in Germany.

I’ve since found sales literature promoting a Ruthemeyer loader with a beam similar to that of the Matbro, so the German company may well have copied aspects of the Matbro design. The articulated chassis, though, was patented, so this was not copied.

For a money-saving subscription to Ford & Fordson Tractors magazine, simply click here