The Intrac story

Posted by Chris Graham on 4th April 2020

Those visiting W Germany’s DLG agricultural exhibition in 1972, got their first glimpse of a revolutionary tractor design; the Intrac story had begun.

The Intrac story: The 2003 was the most successful of all Deutz’s Intrac models, with 2,301 units built between 1974 and 1979.

In 1972, those visiting the annual DLG (Deutsche Landwirtschaftsgesellschaft) agricultural exhibition in West Germany, got their first glimpse of an unusual-looking tractor that proved to be a revolution in tractor design; the Intrac story had begun. It had a roomy cab just above the front axle, a large space behind the cab to mount equipment or a load-carrying platform on, plus a surprisingly short wheelbase.

The centre of gravity was evidently low and the machine’s weight was distributed equally across both axles. In addition to the actual tractor, dubbed the ‘Intrac-System 2000’, also included a large selection of implements and attachments designed for the tractor and the space immediately behind the cab.

Newish concept

The underlying, though not entirely new, idea from Deutz’s development team was that the productivity and efficiency of a tractor could be significantly increased if the driver was protected from the weather, and afforded good visibility in all directions.

The background to the new concept was that agricultural engineers, particularly in West Germany, believed that the development of the tractor in general was largely complete. All farmers in Germany had standard tractors, while tool carriers were mostly used for tasks related to vegetable growing and for special crops.

One of the main features of the Intrac was a front-mounted cab that enabled an unparalleled view of front-mounted implements, such as this Deutz-Fahr KM 25 F mower. All versions of the Intrac featured a large amount of glass, flat floor and the main controls to the driver’s right.

Deutz saw a market for a combination of both types of machine, and companies such as Fahr, Rau, Tröster and Weiste also developed machines and implements based on the concept.

Deutz’s new design, the Intrac, was purportedly the first tractor built in West Germany to have a spacious, heated cab with large glazed areas, a flat floor and easy access to all controls. The cab, hexagonal in form and positioned above the front axle and the engine, gave the driver a commanding view to the front and allowed for seeds, sprays or fertilisers to be carried in a hopper or tank directly behind the cab, thus allowing additional implements – like a seed drill, sprayer or fertiliser spreader to be mounted on the rear linkage at the same time.

Unusual front PTO

The standard, front linkage and front power take-off were also unusual for the time, as was the Intrac-System 2000’s so-called single-phase quick coupler at the front and rear, which is also known in Germany as the Weiste triangle or Accord triangle, owing to the Weiste Accord company. This triangular-shaped coupler enabled the driver to attach implements from the seat, without assistance.

Only five examples of the 80hp Intrac 2005 were built, and the 116hp Intrac 2006 didn’t fair very well either, with only a dozen customers for the model in 1975. This photograph shows a prototype Intrac 2006, based on a 2005 model. (Pic: SAME Deutz-Fahr)

The Intrac system was initially a three-cylinder model known as the 2002, but the five-cylinder Intrac 2005 – with hydrostatic drive – appeared shortly after. The 2002 used numerous components from the standard tractors of the D 06 Series, produced since the late 1960s and, therefore, had a mechanic drive. The air-cooled engine, ZF transmission and adjustable front axle (two-wheel-drive) were taken from the successful Deutz D 5006.

Instead of the full-frame configuration used in the 2005 and 2006 models, the 2002 only had a half-frame, on which the cab was placed at the front. Despite its simplicity, the Intrac 2002 (available with two- or four-wheel-drive) was about 10% more expensive than a standard tractor of the same power output – like the Deutz D 5006. This significantly reduced acceptance among farmers, although it has to be said that the Intrac was significantly better equipped.

Limited success

The success of the D 06 series meant that many, former Deutz dealers can remember selling four or five standard Deutz tractors to every Intrac and, as a result, some didn’t put any effort into selling the new concept. In addition, the Intrac 2002 wasn’t perfect – the front window couldn’t be opened (a popular feature on the Continent), and the noise level in the cab was significant.

The power output of 51hp was also of limited use for many farmers in this area of Europe and, as a result, only 1,159 examples of the Intrac 2002 were sold between 1972 and 1975 (the last of which almost one year after production ended in 1974). Only five examples of the expensive, 80hp Intrac 2005 are said to have been built, and the 116hp, six-cylinder Intrac 2006 could only find a dozen customers during its single year of production – 1975.

The Intrac 2003, which was introduced in 1974, solved many of the problems associated with the 2002, thanks to its cab being better isolated against noise, an openable windscreen and a four-cylinder engine rated at 60hp.

Combining different implements, carried on the front and rear linkages (and platform where applicable), was the basic idea of the Intrac design. This 2003 model is shown drilling sugar-beet with a 12-row crumbler at the front, and a 12-row precision drill on the rear. Access to the cab of the Intrac 2003 was easy, thanks to a sliding door that could also be used for ventilation on warm days.

While the 2002 was painted in the old dark-green Deutz livery, the 2003 was finished in the new, light green ‘Deutz 74’ colour, and the wheels were painted silver from 1978, leading (with the addition of a dark blue chassis) to a colour scheme that became standard for all Deutz and Deutz-Fahr tractors built in and after that year.

The 2003 model was much more successful than its predecessor and, by the time production had ended, a total of 2,301 examples had been produced and sold – making it the most successful Intrac model ever built.

Access issues

Poor engine access remained one of the Intrac 2003’s main faults but, in both two- and four-wheel-drive form, it proved relatively popular. Two special versions, called the ‘Intrac 2003 GI’ and ‘Intrac 2003 TGI’, could be ordered for municipal use and, with the introduction of the Intrac 2004 in 1978, the Intrac 2003 was upgraded.

The wheel size increased, the hydraulic system was uprated and the in-house-designed transmission had additional transport gears to allow for maximum speeds of either 30 or 40kph.

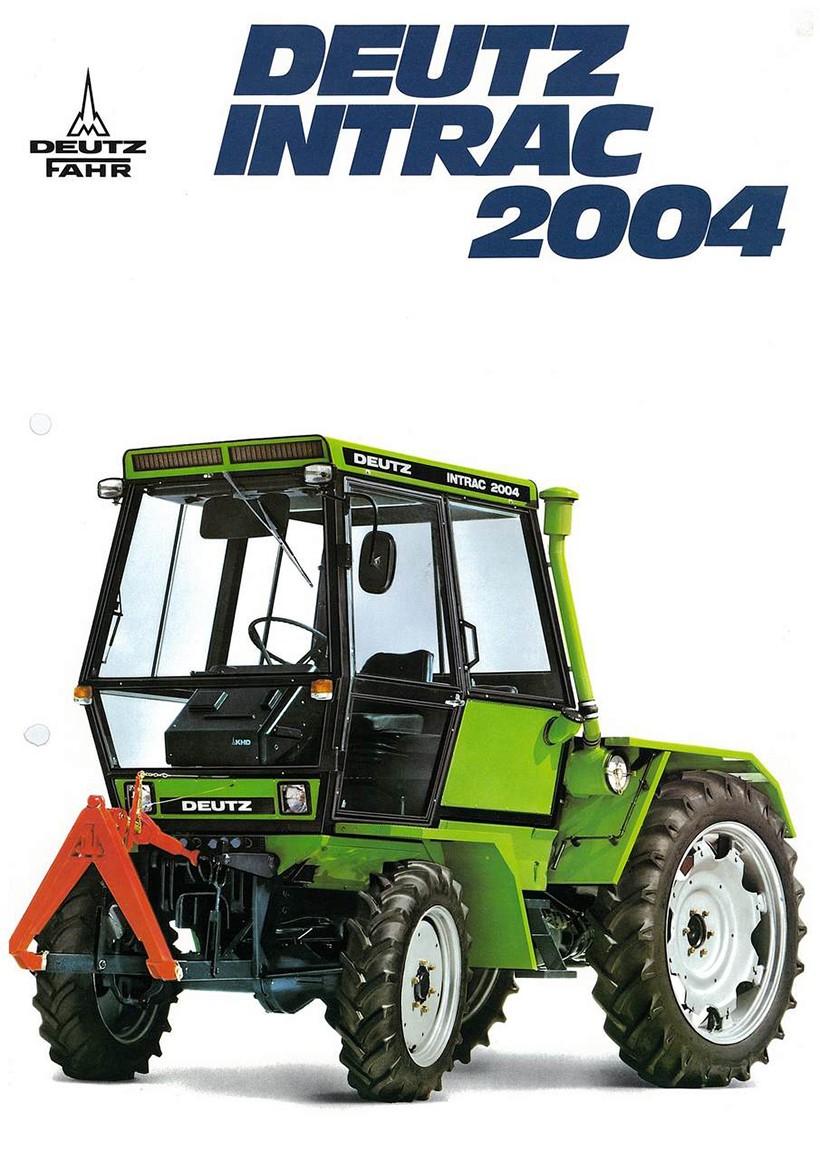

Meanwhile, the 70hp Intrac 2004 was the new top model in the Intrac range. It differed from previous as the cab came from Denmark-based Sekura, rather than the previous versions built by Deutz. The new Sekura unit was also used on the standard D 6806 Special and D 7206 Special tractors.

The Intrac 2004 model was built between 1978 and 1989, and a change in cab design saw the sliding door dispensed with and access somewhat restricted compared to its predecessor. (Pic: SAME Deutz-Fahr)

The cab on the Intrac 2004 had both good points and bad points. On the plus side it could be tilted, which made access to the engine easier, and it was also rubber-mounted to improve operator comfort.

On the bad side, entering the cab was not as easy as on the earlier models, as the new unit was originally designed for standard tractors – requiring the door to be positioned towards the front of the cab, meaning the driver had a somewhat awkward entry and exit procedure, via the mudguard over the front wheel.

Spot the difference! The Deutz Intrac 2003 (left) and 2004 may look similar at first glance, but the later model used a cab built by Sekura, rather than the in-house built unit fitted to the 2003.

Similar to the 2003 model, various versions of the Intrac 2004 were built over the years, including the AS, AT and GI. – where ‘A’ signified ‘Allrad’ (all-wheel-drive), which was actually superfluous as the 2004 was only offered in this configuration. Models with a 30kph transmission were covered by the ‘S’ suffix and ‘T’ signified that it was a 40kph model. The ‘GI’ version was designed for the municipal and industrial sectors, resplendent in a bright orange livery.

Similar approach

Like its predecessor, the Intrac 2004 used a Deutz F4L 912 air-cooled, four-cylinder engine, but power was increased from 60 to 70hp. Production of the 2004 ran from 1978 to 1989 but, about 5,000 Intracs (2002, 2003 and 2004) had been built since production of the concept began.

Similar to the 2003 model, various versions of the Intrac 2004 were built over the years. The ‘GI’ was a particularly robust municipal/industrial version of the concept. (Pic: SAME Deutz-Fahr)

During the course of the 1980s, when Deutz had become Deutz-Fahr, the Intrac series was gradually expanded, leading to the introduction of the high-end 98hp 6.05, 115hp Intrac 6.30 and 150hp 6.60. The cab was now more comfortable, and a 40kph transmission was now the norm.

The six-cylinder models were based on the successful DX range of standard tractors, and were given a simple powershift and electronic control of both front and rear linkages. These larger tractors had equal-size wheels, made possible by the installation of portal gears.

Unlike the 2004’s cab, that tilted to the right of the machine, the later, six-cylinder models had a cab that pivoted at the front, for additional access to the engine. (Pic: SAME Deutz-Fahr)

However, despite more power, more refinement and better features, the concept failed to strike a chord with the bulk of farmers, and sales of the larger Intrac models remained low. The sophisticated technology was ahead of its time and, therefore, relatively expensive. There was also a great deal of competition from standard tractors, which were also now available with front linkages, better cabs, continuously-variable drive and suspended front axles.

Similar to the 2003 model, various versions of the Intrac 2004 were built over the years. The ‘GI’ was a particularly robust municipal/industrial version of the concept. (Pic: SAME Deutz-Fahr)

To save the Intrac concept, Klöckner-Humboldt-Deutz AG and Daimler-Benz founded the Trac-Technik-Entwicklungsgesellschaft (TTE), in 1987. The TTE developed a new range in Cologne, from 68-180hp, with three zones for attachments and equal-size wheels as before. Nevertheless, they were too expensive, and so development stopped in 1990. The last Intrac, a 6.60 model in MB-trac colours, was produced in 1991.

Although the Intrac was ahead of its time, it didn’t get lucky and make the breakthrough that perhaps it deserved. It shouldn’t be forgotten, however, that the Intrac gave considerable impetus to the development of comfortable cabs, and the increased use of front-mounted implements. The fact that this is taken for granted today is due in part to the Intrac concept.

Access for the operator was better on the 6.05, 6.30 and 6.60, with a door at the rear of the cab and wide steps. (Pic: SAME Deutz-Fahr)

Intrac 2003 & 2004 specifications |

||

| Type | Intrac 2003 | Intrac 2004 |

| Power | 60hp | 70hp |

| Engine model | Deutz F4L 912 H | |

| Engine type | Air-cooled, direct-injection diesel | |

| Cylinders | 4 | |

| Bore | 100mm | |

| Stoke | 120mm | |

| Capacity | 3,768cc | |

| Fuel capacity | 85 litres | 82 litres |

| Transmission | 8 fwd, 2 rev or 12 fwd, 4 rev | 12 fwd, 4 rev |

| Maximum speed | 25 or 30kph | 25, 30 or 40kph |

| Width | 1,890mm | 2,025mm |

| Wheelbase | 2,200mm* | 2,200mm |

| Weight | 3,450kg* | 3,500kg |

| Front wheels** | 7.50-18 or 10.5-20* | 10.5-20 |

| Rear wheels** | 14.9-28 | 16.9-30 |

| Produced | 1974-’79 | 1978-’89 |

| Number built | 2,301 | approx. 2,000 |

* Four-wheel drive model

** Typical tyre size

To subscribe to Tractor & Machinery magazine, simply click here