Allis-Chalmers HD-6 crawler

Posted by Chris Graham on 3rd February 2020

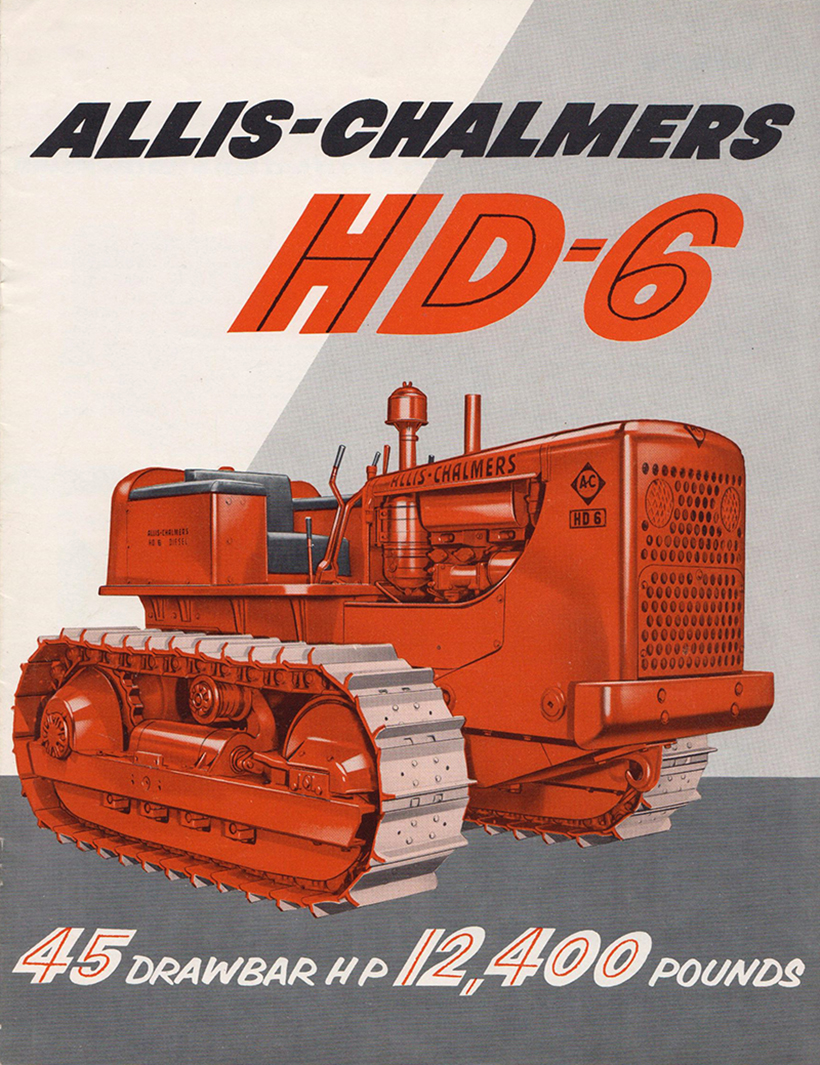

The Allis-Chalmers HD-6 crawler launched in 1955, with high expectations which, as Paul Tofield explains, were proved thoroughly justified

The Allis-Chalmers HD-6 crawler brought big tractor design features to the 50 drawbar horsepower class

Although the Allis-Chalmers HD-6 crawler was the smallest in the range by drawbar performance and weight, it outsold its bigger brothers significantly. When production finally ceased in 1974, over 25,000 units had been produced. The HD-6 outsold the larger HD-11 by more than 10,000, and remained in production for several years after the bigger models – which also began their lives in the mid-1950s – had been redesigned.

The production figures for the HD-5 eclipsed every other Allis-Chalmers crawler; it took 19 years of sales of the HD-6 to achieve sales of 25,171 units, due to the steady contraction of the world market for small crawler tractors. The HD-6 built on the success of the HD-5, offering big tractor features like unit construction, which allowed major components to be removed without disturbing other key assemblies, and double reduction final drives.

Launched in 1955, HD-6 production ceased in 1974 with sales of over 25,000 tractors

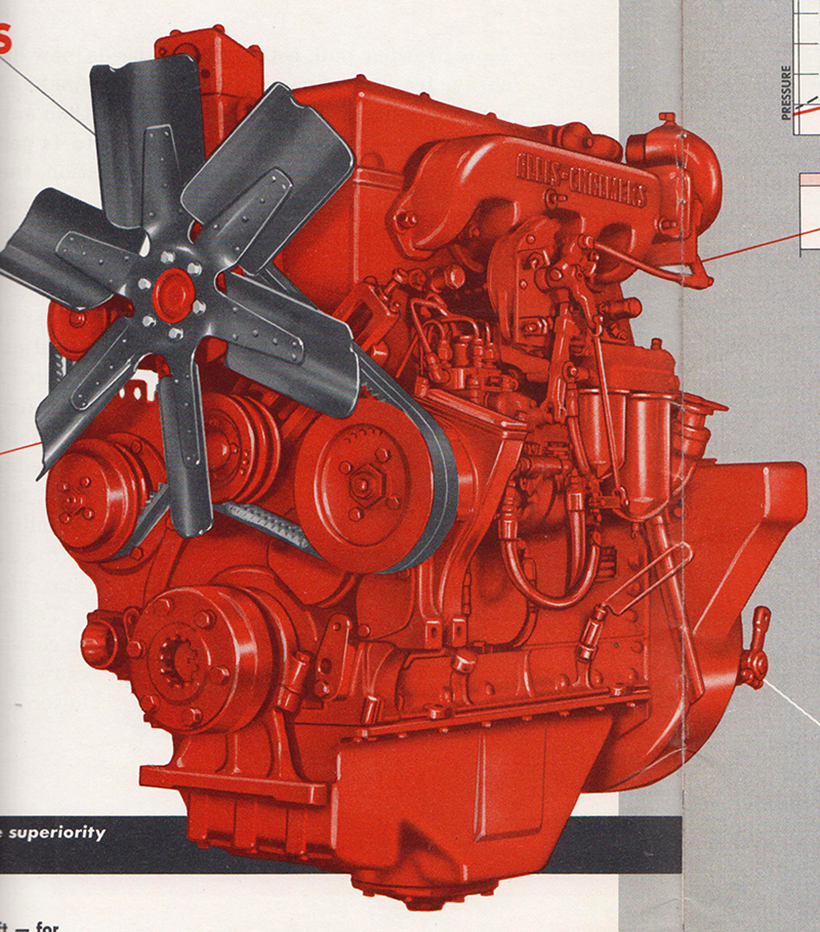

Allis-Chalmers diesel

The old, two-stroke, twin-cylinder 2-71 General Motors engine was replaced by a 344cubic inch, four-cylinder Allis-Chalmers diesel, based on the Buda engine design, otherwise it was very much business as usual for the new HD-6. It was promoted as an operator’s tractor and, with no requirement for daily lubrication, the reduced down-time appealed to owners and mechanics alike.

While the Allis-Chalmers HD-5 was a good, solid seller, it never broke the 5,000-units-a-year production barrier; this accolade was achieved by the HD-6 in 1956, its first full year of production which accounted for 5,318 tractors.

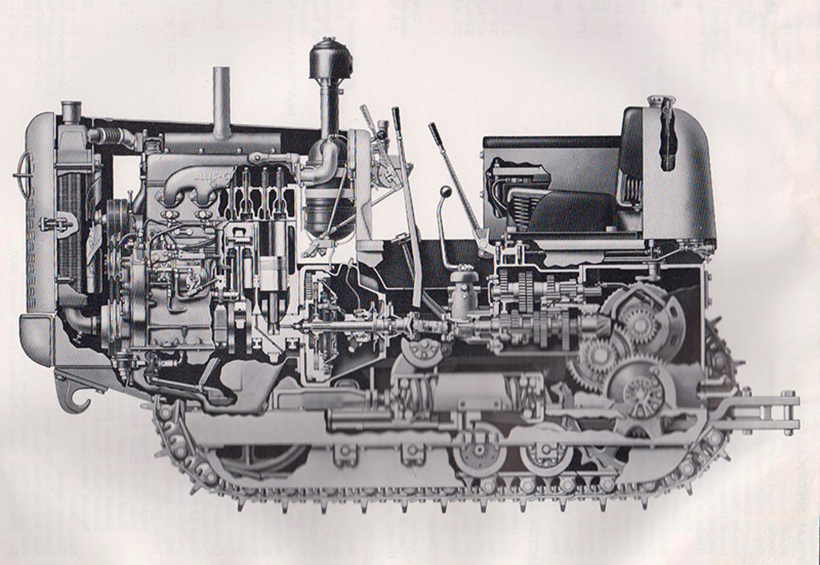

This cutaway illustration was used in many sales brochures to highlight the exclusive benefits found in the HD-6 design

The initial HD-6 sales material billed it as a 45 drawbar horsepower tractor weighing 12,400lbs, with an extra seven drawbar horsepower over the outgoing HD-5. The obvious competitors to the HD-6 were the Caterpillar D4 U series which, following its 1954 refresh, offered 48hp at the drawbar, and the International TD-9 models. The old TD-9 of 29 drawbar horsepower fell well short of its competitors, and was replaced by the TD-9 91 series during 1956, which boasted almost 42 drawbar horsepower from its D350 International diesel.

A study of the production volumes for 1956 indicates that Allis-Chalmers was a serious player in the 12,000lb 45 drawbar horsepower market, by manufacturing 5,318 units. Meanwhile, International made 5,127 tractors, some of which received Drott shovel attachments. Like International, the Allis-Chalmers figures didn’t split out those base tractors which were fitted with Tractomotive shovels. However, Caterpillar separated the new 955C Traxcavator under a 12A prefix. Therefore, to get an idea of Caterpillar’s sales, the 1,621 955s can be added to the 4,808 Caterpillar D4 U series. So, it could be concluded that the 1956 figures suggest these three competitive tractors had similar market shares.

The base tractor weighed about 12,600lb and was targeted at the market dominated by the Caterpillar D4 U series

Short-lived impact

Sadly, for Allis-Chalmers, the impact of 1956 wouldn’t hold long-term. When International creased production of the TD-9 in 1974, the final tally was around 27,500 units. Caterpillar remained dominant in this market by getting over 57,000 D4 U series tractors to customers between 1947 and 1959, before adding any additional sales of equivalent Traxcavators with 1.5-yard capacity shovels. The year 1956 held another significance for the HD-6, as it was tested at the University of Nebraska, where the test tractor showed a much higher drawbar power than the 1955 sales brochures stated. The HD-6 was now proven to deliver 52 drawbar horsepower, rather than the original manufacturer’s estimate of 45.

As well as the extra power of the HD-6, it also featured 24-volt direct electric starting. The new International TD-9 91 series crawler retained the petrol-start diesel technology developed in the late 1930s. Caterpillar remained faithful to the horizontal, two-cylinder donkey-starting engine for the D4 – also a product of from the 1930s – which, for a fortunate operator, may have been fitted with a six-volt starting motor. Thanks to the use of General Motors’ two-stroke diesels with direct electric start, Allis-Chalmers buyers were already familiar with the ease of this starting method.

The Allis-Chalmers HD-6 crawler sales brochure of 1955 highlighted a dozen benefits which the company saw as exclusive to its product. Table 1 lists these benefits, while some of them were continued from the HD-5, a number of new features were aimed at improved serviceability and ease of operation and repair.

When first introduced, the Allis-Chalmers HD-6 crawler used a four-cylinder, four-stroke diesel with the Lanova energy cell indirect injection system. The engine ran at a rated speed of 1,800rpm. Sales brochures still showed this engine as the power unit in May, 1959. Allis-Chalmers engineers began developing a direct-injection engine based on the Buda model in 1958. It would appear that this new engine, designated the 6000, was used in the HD-6 from 1960, with tractor serial no 13322.

A four-cylinder, 344 cubic inch diesel used the Lanova energy cell indirect injection system for combustion

Power control

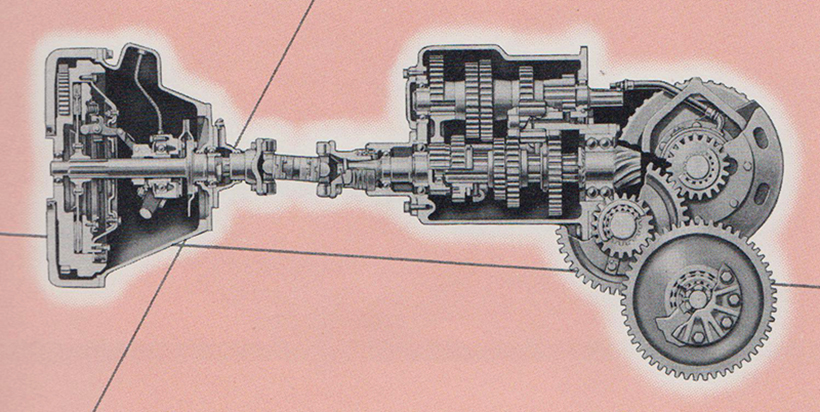

Early tractors used a Rockford main clutch; the parts books indicate that the Auburn clutch was fitted from tractor 3006 of 1956. Drive from the clutch was transmitted to the five-speed forward and single reverse gearbox through a double universal joint. The forward speeds remained the same as the old HD-5 tractor. A four-speed forward and two-speed reverse transmission was unique to the track shovel application.

The HD-6 was available in either 44-inch or 60-inch track gauges, with standard- and long-track frames offered for both gauges. The standard frame had four truck wheels, the long-frame carried five wheels. The HD-6F specification included 60-inch gauge, and extended long-track frame for six truck wheels, and was intended for sideboom equipment. Further changes in the early 1960s saw the introduction of the HD-6E, which eventually replaced the HD-6A. A new HD-6, with a torque converter and two-speed powershift transmission, as the HD-6EP, arrived for bulldozer work.

The rigid frame to carry the engine, clutch and gearbox was not common in crawlers of this size and power

With the concept of manufacturers offering a full line of matched equipment well established, Allis-Chalmers offered either in association with or often by purchase of a key equipment supplier, a range of matched hardware. A customer’s HD-6 could be fitted with either a 10ft 6in hydraulic angle blade, or an 8ft straight blade, the new heavy-duty hard nose carrying a pair of rams.

A Carco E24 rear towing winch was offered. An HD-6 with a rear cable control unit could handle the Allis-Chalmers Model 44 open-bowl towed scraper of 4 yards struck/5.5 yards heaped capacity. A rear-mounted, lightweight ripper made by Tractomotive with five shanks, increased the versatility of the HD-6 also, and made a decent counterweight for another Tractomotive product, a 1.5-yard hydraulic shovel.

Unit construction allowed the removal of the engine, clutch, gearbox and steering clutches without disturbing other parts of the tractor

Hydraulic shovel

With the launch of the HD-6, the Tractomotive 1.5-yard shovel was designated the TS-6. The hydraulic shovel design had met with great success on the HD-5. The Tractomotive Corporation was founded by Van Dobeus, who began his career with Allis-Chalmers as a field service engineer, and was ultimately appointed chief engineer. Following his early death in 1952 aged just 49, the Tractomotive company continued and became part of Allis-Chalmers in 1959. In mid-1959, the HD-6 and TS-6 combination appear to have been promoted as the HD6G.

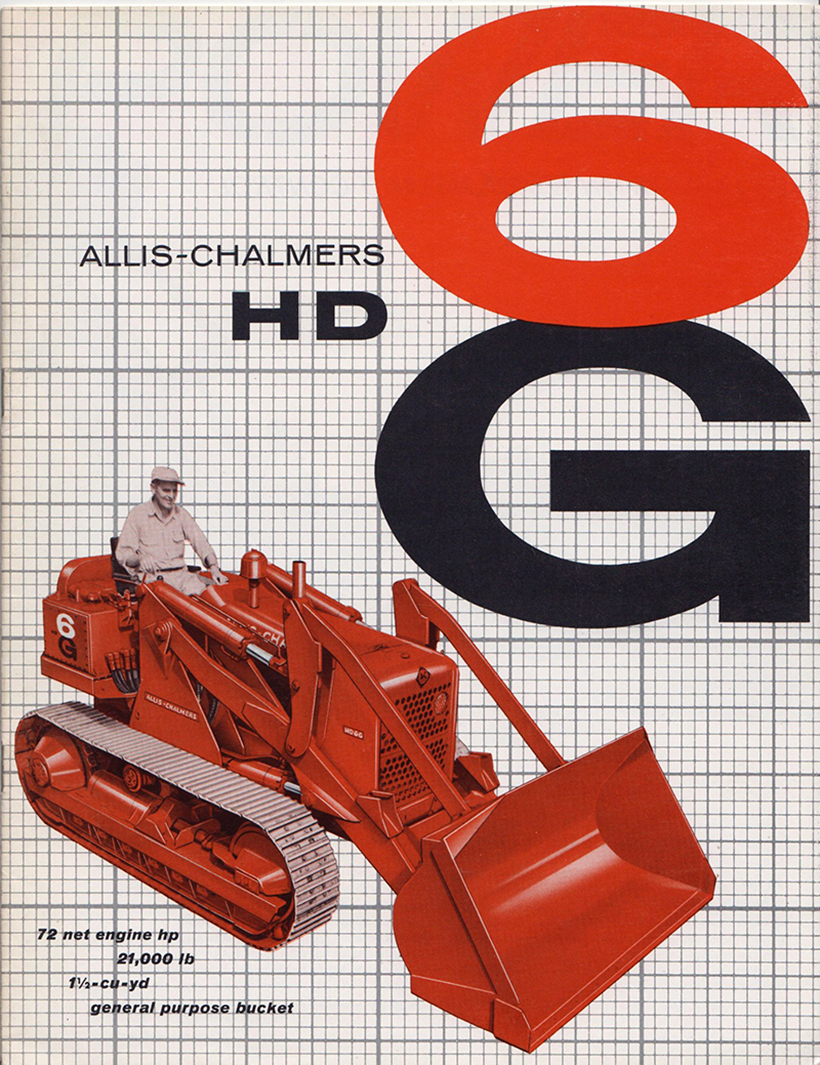

Although the ‘G’ postscript had denoted the specification of the six-truck wheel track frame and other specific modifications for shovel work for some time, the HD-6 shovel sales brochure of July 1959 highlights 6G strongly on the leaflet cover and the side of the tractor. The leaflet showed the redesigned loader frame and linkage. While increasing the operating weight from 19,600lb to 21,000lb, the loader improvements made the operator platform more of a walk-through design, with much care taken to avoid ‘shin busting’ levers and brackets, to use the words of the text in the leaflet. There will be countless track shovel operators who can identify with the intense pain of a cracked shin from that scenario!

The HD-6 sales volumes prove the tractor was well respected in its many applications. It was well-appointed with features like front electric lighting, crankcase guard and exhaust muffler as standard, rather than additional cost accessories. As a logging tractor with protective canopy, extra brush guards, angle blade and rear winch, it was highly regarded by loggers who commended it for its low centre of gravity for working on difficult gradients. Many are still active today, with only the problem being finding parts for a 60-year old tractor reducing the HD-6 population.

The cover of the HD6G 1.5-yard track shovel, dated July 1959, shows the redesigned shovel linkage and frame

Too few UK sales

It’s a shame that only a few buyers in the UK decided to buy HD-6 tractors. A small number of machines were sold into agriculture, including one which has been on the same farm from new. The owner, an Allis-Chalmers enthusiast of long standing, farms in the East Midlands. Some recently-found sales record cards from 1964 and 1965, suggest sales of one HD6G track shovel a month. Of the 21 machines sold, most went to small plant hire companies, but it’s interesting to note that the London Brick Company bought two with consecutive serial numbers, in 1964. Sales to Cardiff Plant Hire accounted for five of the 21 tractors recorded. Table 2 breaks down the cost of the tractor, showing import duty and shipping costs, which account for around a quarter of the final cost of the machine. The £5,800 HD-6 had to compete with Caterpillar 955F built in Glasgow, and retailing at £6,800 and, latterly, the 951 Traxcavator, again a Glasgow-built machine, selling for around £7,000.

As the little tractor with the big tractor features, the Allis-Chalmers HD-6 crawler deserved to sell well. It probably spurred the competition to develop their product offerings. Caterpillar was only able to match the HD-6 in styling and performance with the arrival of the D4D, in 1964. Allis-Chalmers had to be innovative with products as the way of taking business from the competition, but this came with a high level of risk. Failed innovation within a business like Allis-Chalmers – once summed up in one sentence ‘too many businesses; too few dollars’ – meant a failure had a serious impact on the business.

Table 1

Twelve Benefits exclusive to the HD-6

(Source 1955 sales brochure)

- All-steel main frame

- One-piece steering and final drive case

- Straddle-mounted final drive gears with shafts supported at both ends on taper roller bearings

- Heavy-duty track frames

- 1000-hour lubrication intervals for truck wheels

- Unit construction allowed major components to be removed with disturbing other assemblies

- Ceramic master clutch lining

- Wrap-round radiator guard hinged for ease of access

- Diesel engine mounted on rubber cushion blocks

- Direct 24-volt starting

- ‘Follow through’ combustion sustained pressure on the piston during its downward power stroke

- Daily lubrication tasks avoided

Table 2

Final price of an HD6G sold in Britain, February 1965

Base machine £4,553

Bucket £136

Cab £65

Shipping £308

Duty £613

TOTAL £5,675

To subscribe to Classic Plant & Machinery magazine, click here