Atlantic locomotive new-build update

Posted by Chris Graham on 2nd April 2021

Recent lockdowns have upset progress with the Brighton Atlantic locomotive new-build, but the steam engine project is still moving forwards.

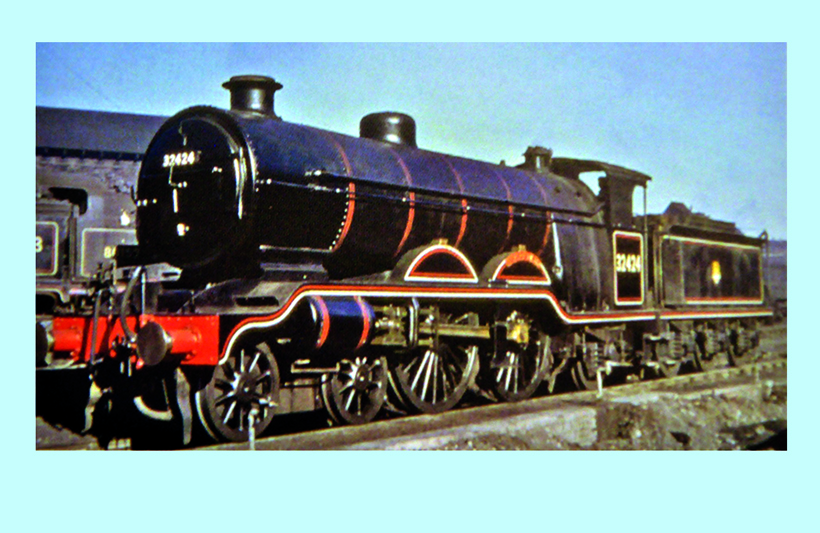

The original, BR locomotive No. 32424, Beachy Head, being prepared at Brighton for its final rail tour in 1958. (Pic: Colour Rail)

Unfortunately, due to the Covid-related lockdowns in in the UK, work on the Beachy Head locomotive reconstruction being undertaken at the Bluebell Railway, has fallen somewhat behind schedule. The team working on the exciting, Atlantic engine new-build, has had its work on the boiler lagging and clothing hampered by the restrictions, but reports that some progress has still been made.

The firebox clothing sheets have sufficient paint on them to allow them to be placed in position on the boiler.

So far, the steam feed, delivery and overflow pipes have been made and fitted to the injectors. But the remaining sections going to the combined injector steam and non-return valves on the backhead will have to wait until the boiler is installed.

The basic boiler clothing sheets have been laser-cut and rolled, although each still has about 8in of excess material on each end that needs to be removed. This is needed to allow the radius of the rolled sheet to extend fully to the ends. Although these sheets look thin, it takes three people to move each one, as they both unwieldy and surprisingly heavy. A lot of careful work will be needed on these to get them to fit accurately to the boiler, with cut-outs for hand rail knobs and splashers etc being needed. One of these latter cut-outs actually straddles the joint between two sheets, and also has a boiler band running over it.

All the super-heater elements have been installed into the boiler. (Pic: Fred Bailey)

The firebox clothing sheets have sufficient paint on them now to allow them to be placed into position on the boiler, primarily to create some more space in the shed so that the team can undertake further work on the barrel and tender clothing. All the insulation material to wrap the boiler is in stock, and is now being stored in the tender coal space. Work’s starting on the corner sheets that bridge the gap between the firebox sides and the backhead, and also the firebox sides to the throatplate.

All the coal rails and their infill pieces – plus the beading around the top edge – are now fixed, and the heads of the fastenings (seen above as silver spots) will be painted shortly. (Pic: Fred Bailey)

All of the coal rails and their infill pieces, plus the beading around the top edge are fixed, and the heads of the fastenings will be painted shortly. But the team will purchase the first two tender clothing sheets, and work on riveting various pieces to them, before fitting. Only then will they obtain the next two sheets, which curve around the back. Once again, handling is a problem as each plate is 10ft 6in long, 4ft 6in high, 3mm thick and weighs about 200lbs! The front handrails are fitted, and work is now taking place on the cab doors and the toolboxes.

BR engine No. 32424, Beachy Head, on the turntable at Newhaven, on April 13th, 1958. (Pic: Colour Rail)

Finally, all of the super-heater elements have been fitted into the boiler, so things are moving forward despite the Covid-related difficulties, which is good to know.

For a money-saving subscription to Old Glory magazine, simply click here