Industrial Stuart-Turner P55

Posted by Chris Graham on 4th June 2020

Two-stroke engines are like Marmite; people either love or hate them. But Philip Thornton-Evison is a big fan of his industrial Stuart-Turner P55.

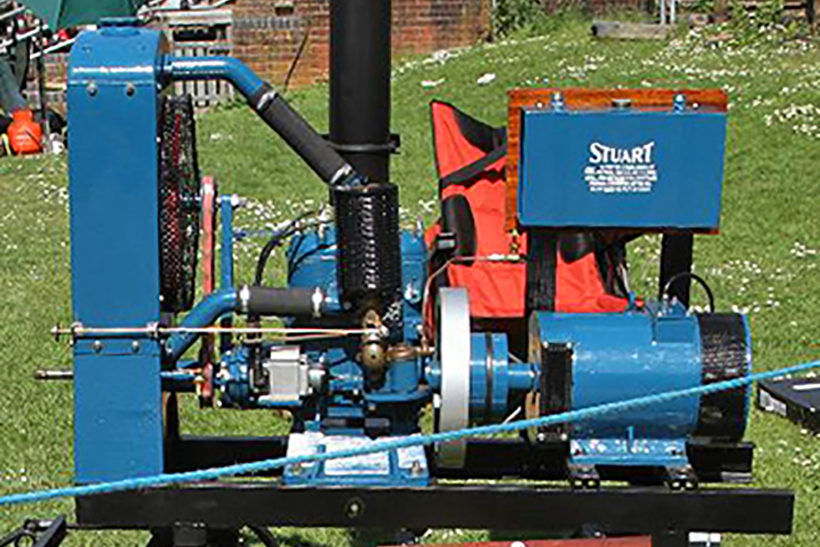

Industrial Stuart-Turner P55: When I collected it, garish red and green paint had been plastered all over the pre-existing rust and dirt on the engine.

Introduced in around 1936, the P55 is basically a doubled-up P5. Displacing 535cc, it develops 7hp at 1,500rpm and, while the marine version is relatively common, the industrial versions – like this one – turn up far less frequently.

Initial assessment

On first sight, ‘my’ example appeared essentially all present and correct, if rather garish. There was a very imposing radiator to admire, and it had both good compression and some sort of spark. It could be just about persuaded to run, though it wasn’t the greatest. However, as the asking price was very reasonable, coin of the realm changed hands and it was taken home to my shed.

There was a huge amount of debris in the radiator. I reckon it must have been repeatedly filled from the bottom of a pond!

Once there, I’m afraid to say, it stood for a good number of years. My research showed that what I’d actually bought was slightly less than one half of a 230V, 2.5kW military generating set, probably dating back to the Second World War. The alternator had been removed by the simple expedient of sawing the frame in two.

Also missing were the fuel tank, the field regulator and various other miscellaneous but useful parts. A flat-belt pulley had been grafted on to the flywheel which, on these engines, isn’t a good idea as they’re simply not designed for it.

Oriental alternator

Fast-forward a decade or so and, but that stage, I’d managed to acquire a proper, ex-WD spares kit, containing various useful items. However, I was still at a loss regarding what to do about the missing generator. It needed to be one that ran at 1,500rpm, to match the engine speed. However, my salvation came from the Orient.

A new, 3kW, 1,500rpm alternator was sourced from the Orient.

What are generically known as ‘ST’ alternators were then available in the UK and, even more usefully, there was a 3kW, 1,500rpm model in the range. So, I ordered one and, after a wait of a few weeks, it was delivered to my door. Not without a bit of effort, I may add, as it weighs in excess of 150lbs; it came on its own wooden pallet!

I stripped the alternator, fitted better bearings and ‘faked it up’ to look more in keeping with the age of the Stuart-Turner.

So now that I had both an engine and an alternator the tricky bit could begin, which was encouraging them to play nicely together. This wasn’t so much of a restoration, but more a fabrication project. I wanted a challenge, and now it looked as if I had one.

The alternator was given to a very good friend of mine who is a proper engineer. He machined the shaft to make it fit the original S-T coupling; a more involved process than you might imagine. I also did some work to try and fake the alternator up to look older than it was; for good measure, I replaced the Chinese bearings with SKF ones.

Restoration process

The red and green paint on the engine had been plastered over all the pre-existing rust and dirt; not a pretty sight. Where possible, the current trend is to try and preserve an original factory finish, but this was so far gone it was going to need stripping and repainting. I set to work and it wasn’t long before the pile of dismembered parts started growing.

There were brazed frost repairs on both the block and bottom radiator tank, but these had been done competently, possibly still in its military days. As can be seen from the photograph here, I also found a huge amount of debris in the radiator. I reckon it must have been repeatedly filled from the bottom of a pond!

Once dismantled, it was obvious that the engine had been subjected to a fair amount of abuse. In fact, I was sure it had suffered at least a partial seizure at some point. Fortunately, I was able to acquire a donor engine, and it was rather a case of ‘mix and match’, to use the best parts of each.

The engine base and radiator stand set out to determine the basic dimensions needed to fabricate a trolley.

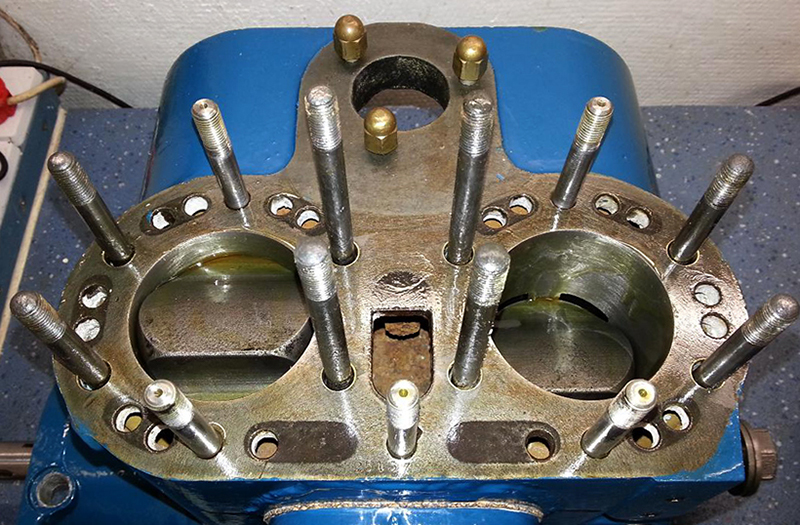

A twin-cylinder. two-stroke isn’t a particularly complex beast and, with the aid of photographs (this is where a mobile phone really comes into its own!) and a bit of imagination, it went back together without any real problems. The spares kit contained a complete set of new gaskets, which was a real time-saver. As ever, though, I seemed to spend ages on the lathe making various little bits and pieces although, to be honest, I do rather enjoy producing swarf.

Reassembly of cylinders and studs.

By the time the whole set was assembled on its newly-fabricated trolley, it looked impressive, especially with that large (and very heavy radiator). The fuel tank was originally intended for a Lister A type, but I merely turned it on its side. The vinyl lettering was surplus to an earlier project. The more observant may have noticed the paint colour isn’t one that ever came out of Henley-on-Thames. It is, in fact, LNER Garter Blue, from Craftmaster paints and, to my mind, looks very smart.

The engine was reassembled on the newly-fabricated trolley. The exhaust pipe seen here is the original.

The start-up

The excitement of the first start after restoration was rather tempered by the fact that it wouldn’t. No matter how much I swung the handle and swore, all that happened was the occasional, massive back-fire. Another good friend gently suggested that I might like to check the timing and, sure enough, it was 180° out, as I’d timed it on the wrong cylinder.

With this beginner’s error corrected, it would start, but didn’t then run at all evenly. After checking everything else, we concluded the magneto – which had been professionally overhauled – must be the problem. I gave this a certain amount of consideration, then sent it off to a different professional who confirmed it wasn’t right, and proceeded to do a better job.

If the first bloke couldn’t get it right once, I was dubious of his ability to get it right at all. However, after refitting the magneto, and taking care to time it correctly, starting and running was absolutely fine. The alternator is effectively self-regulating, with no external controls being necessary.

A few observations

The P55 is mainly a device for converting fuel into noise and smoke. At full chat it sounds absolutely glorious, but is capable of making a gallon of petrol disappear in about 90 minutes. This isn’t an engine to take to a three-day rally! It really needs that big radiator; it’s not just there to look good, and it must take around a horsepower merely to drive the cooling fan!

Probably due to the botched drive pulley, the crankshaft was slightly bent, and you could see a slight wobble on the flywheel as it ran. This annoyed me beyond measure. At the time of writing, I’m in the process of fitting a different – and hopefully better – one. The exhaust system will also be modified. Even though the Stuart runs on a 50:1 petroil mix, it’s a bit of a messy eater, and throws out oil spots. The donor engine came with an original, low-level exhaust system, which will be cleaned and painted before being re-used.

The engine’s first outing was at the Amberley Rally, in 2019, where it looked smart in LNER blue.

So, there we have it. Sadly, it seems to be one of those unloved engines that nobody really wants, but I’ve very much enjoyed this project, and it’s something that I’m pleased to have in my collection.

I hope to take it to a few events in due course so, if you see a man looking disconsolate, surrounded by empty fuel cans and wreathed in clouds of blue smoke, that’ll be me! No wonder most of these went to the military; I reckon only the government could afford to run them!

To buy a money-saving subscription to Stationary Engine magazine, simply click here